With such a variety of CNC router software on the market, it can be a pain to figure out which covers your needs without being overly complicated. In this guide, I’ll compare my hands-on experience with all the most popular software across important factors like user-friendliness, compatible operating systems, range of features, customer support, and much more.

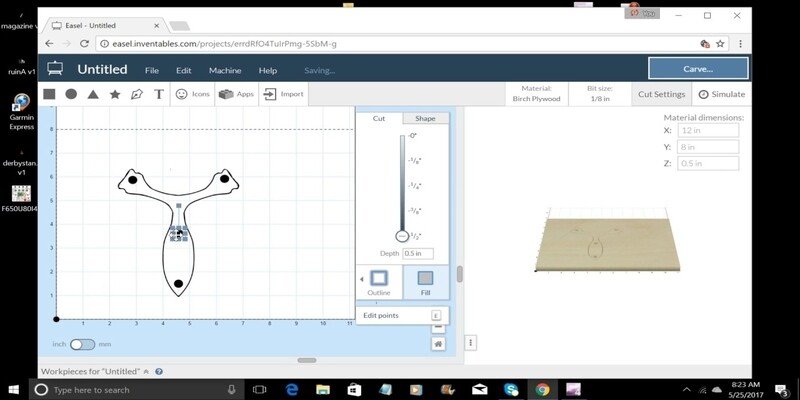

Easel is one of the best CNC software for most users – especially beginners. The free version covers everything you need in a single software, with a user-friendly interface that is compatible with the vast majority of CNC routers.

More advanced users may look to use more specific applications to get access to advanced tools not available in “all-in-one” solutions:

- CNC design software (CAD) lets you create 2D or 3D CAD designs

- CAM software for creates toolpaths and exports g-codes that your CNC router can interpret

- CNC controller software runs your machine to create perfect carvings and cuts

I recommend Fusion 360 as a CAD software with advanced features and extensive toolsets, while GRBL Candle is a dependable free CNC controller offering simplicity for beginners

CNCSourced Recommends

All-in-one software:

Best CNC CAD software

Free CNC controller software / G-code software for CNC:

Best CNC controller software (professional):

You’ll also want to consider price. While there is free CNC software that can be used by anyone, some of the best software can cost hundreds of dollars – so you need to find a program that covers your needs without overspending.

So take a close look at the key aspects of each CNC software to help you make the right choice.

All-in-one CNC Software

1. Easel / Easel Pro – Best CNC Software For Beginners

- Price: Easel is free, Easel Pro is $24/m or $233/year

- Operating Systems: Windows / Mac / Linux

- Where to get it: Easel

Pros

Seamless compatibility with most common CNC routers.

Continuous improvements and new features introduced.

Free version available.

Cons

Can be difficult for beginners to navigate through the software.

Made by Inventables, makers of the popular X-Carve CNC router, Easel is sold as the easiest and most beginner-friendly CAD-CAM software for CNC around.

It’s also a CNC control software. So, even if you’re not using Easel’s CAD/CAM, It’s easy to import g-codes from tools like Fusion 360 into Easel and get machining right away for a convenient workflow.

Easel has seamless compatibility with most common CNC routers well beyond their X-Carve machines, including 3018 CNC routers by brands like Sainsmart and Mysweety, as well as larger machines by Millright, BobsCNC, Shapeoko, and many more. You can also export gcodes for machines like Maslow, though you can’t directly control them with Easel.

The all-in-one focus saves you hassle if you’re a beginner or time-pressed, and you’re able to design, import, and get carving all within the one CNC CAM software.

An online CNC software, Easel frees you from downloading and launching software continuously, as well as letting you easily store your designs and changes in the cloud. Easel is only improving, too, with continuous improvements and new features introduced, including v-carving, better tool paths, tiling, and new graphics added all the time.

If you get stuck, there’s a great community built around both Easel software, and the X-Carve machines, to help you out. Also, check out Inventables’ Easel 101 videos if you’re a beginner and want to get learning.

Easel Pro has v-carving, more advanced tool paths (raster carving for optimizing the direction of your CNC router’s cut based on the length/width of your part, ramping plunges, etc), access to the Pro design library with over 3 million designs, a customizable font library, and much more — but the very serviceable basic version is free.

CAD Design Software for CNC

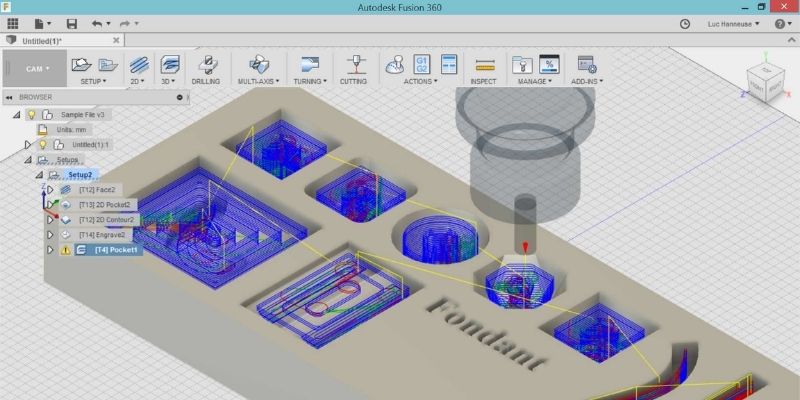

2. Fusion 360 – All-purpose CNC CAD-CAM Software

- Price: Free for students and personal use, and $545 annually for commercial use

- Operating Systems: Windows / Mac

- Where to get it: Fusion 360

Pros

Capable of 2D and 3D CNC designs.

Free version is available as well as a free student version.

A great CNC CAM software for generating g-code files.

Cons

Free version is very limited.

With a huge market share and a favorite of many makers, Fusion 360 is a great all-in-one CAD/CAM software for CNC. Capable of creating 2D and 3D CNC designs, Fusion 360 also has advanced CAM and a g-code editor and CNC simulation tools based on your chosen toolpaths.

While Fusion 360 is free for personal use, you’re limited compared to the paid version. You only get 10 active and editable Fusion 360 documents, can’t use it for 4 or 5-axis CNC, can’t export .dxf, .dwg and some other file types, and you don’t get access to premium tools like HSMWorks.

For hobbyist use you’re probably only using a 3-axis CNC machine though, and may not need complex simulation tools — you just want to get making with your CNC router. Fusion 360 is also free if you’re a student for educational purposes.

If you’re upgrading to Fusion 360’s paid version, you can use 4 and 5-axis functionalities, and it works for a variety of CNC machines beyond just CNC routers: waterjet cutters, plasma cutters, laser cutters, FDM 3D printing, and more. Fusion 360 gives you a wide range of tool path templates to save you time and make you more efficient — making you more money. Adaptive clearing, parallel passes (for detailing), circular and pocket clearing, 2D contours, and many more custom options cut down on experimenting so you can get right to work. It’s one of the best CNC programming software tools out there, and a great CNC CAM software for generating g-code files.

Naturally, post processors are available for a wide range of machines, so you don’t need to worry about compatibility — you can find these in the Autodesk Post Library. Its popularity means there’s a wide range of resources for learning specific elements, and ensures it’ll be supported for decades to come.

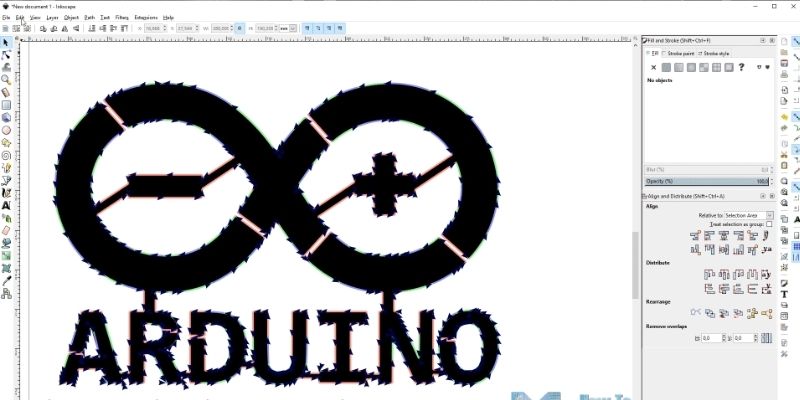

3. Inkscape — Free 2D Vector CNC Design Software

- Price: Free

- Operating Systems: Windows / Mac / Linux

- Where to get it: Inkscape

Pros

Free and open-source.

Great for laser cutting and CNC cutting.

Great for 2D designs and as CNC lettering software that can save you money.

Cons

G-code is not built in natively.

Inkscape is a free and open-source CNC software commonly used in laser cutting for its great 2D design tools. And for all the same reasons, it’s great for 2D CNC cutting as vectors work perfectly for projects with text and image designs.

For more complex and advanced design projects, using Inkscape (free) or Adobe Illustrator ($20.99/month) can be easier for the initial design work, before exporting the design as an SVG file and transferring it.

You can also use Inkscape to save money, as some free CNC software limits you design-wise, such as Easel’s limited number of fonts in their free version. This makes it an effective free CNC engraving software, as well as for CNC carving. More advanced makers will have better (and more expensive tools), but if you’re having fun with your 3018 CNC router, Inkscape is a great companion for 3018 CNC software and quickly makes simple designs.

While for convenience you could upgrade and pay $24 per month for Easel, more shrewd CNCers may consider designing the project in Inkscape for free, taking advantage of the limitless font options, before exporting the SVG and importing it into Easel for creating the toolpaths.

While not built in natively, you can install a third-party g-code extension to export g-codes for your control software, but by default, Inkscape can export DXF files for CNC, and a range of other formats. Overall, it’s great for 2D designs and as CNC lettering software that can save you money.

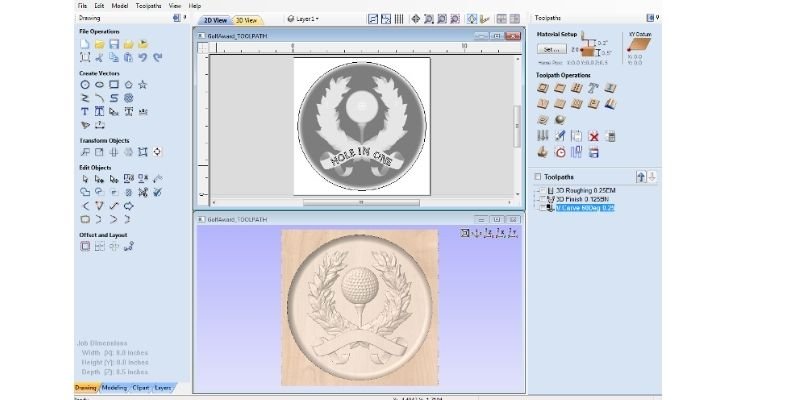

4. V-Carve Pro / Desktop – Professional CAD/CAM Software for CNC

- Price: $699 / $349

- Operating Systems: Windows 7 or newer

- Where to get it: V-Carve

Pros

Lets you create complex 2D, 2.5D, and 3D CNC toolpaths.

Unlimited free trial.

Supports a 4th axis/rotary attachment module for any 4 axis CNC makers.

Cons

Free version is heavily limited in features.

Laser module license is needed to use the software for laser projects.

Vectric’s V-Carve CNC software comes in two main options: V-Carve Desktop, and V-Carve Pro. While they’re mostly similar, there are a few key differences: mainly the limited job and tool path sizes in V-Carve Desktop of 25 x 25 inches — so if your CNC is larger than 6060 then you’ll need to upgrade.

You can create 2D CAD designs with VCarve, but you can’t create 3D designs. However, VCarve allows you to import 3D designs to use with its CAM tools.

As a CAM software, V-Carve lets you create complex 2D, 2.5D, and 3D CNC toolpaths and includes v-carving textures. With V-Carve you get access to Vectric’s expansive 3D clipart file library for creating models quickly, and the software supports a 4th axis/rotary attachment module for any 4 axis CNC makers.

However, if you plan to use V-Carve’s laser cutting and engraving software, keep in mind that you’ll need a further license. While only $49, some may be irked by the extra cost to use it for laser projects.

Overall however, V-Carve Pro and Desktop are advanced CNC software tools for hobbyist and professional carving, and the one-off license fee may swing it in your favor if you’re not a fan of monthly subscriptions, as with Easel or Carveco.

You also get an unlimited free trial that doesn’t expire — but the downside is you’re heavily limited on features, for example, you can’t export output files. Mac users needn’t fret, as though V-Carve isn’t natively designed for MacOS, you can run Parallels Desktop and run it without issue — many CNCers worldwide use this exact method for their workshops.

5. Carveco Maker — Powerful CNC CAD Software

- Price: $15/month

- Operating Systems: Windows

- Where to get it: Carveco Maker

Pros

Speeds up your workflow.

Used for both 2D and 3D design.

Intuitive UI.

Cons

Only compatible with Windows, not Mac.

A competitor to V-Carve in the CNC CAD software category for both 2D and 3D design, Carveco Maker instead goes down the monthly subscription route, costing $15/month, or one month free if you sign up for a yearly subscription.

The software focuses on hobbyists and small business users, speeding up your workflow so you can work productively and create things like custom signs, boards, and 3D carvings — and earn more, too.

The UI has similarities to Photoshop so it feels intuitive, not alien as some more basic CNC router software can. Carveco Maker supports all major image file types, from bitmap and PDF to jpeg, tiff, and vector files like dwg, and dxf, and also features a 3D clipart library like V-Carve for quickly prototyping designs or adding other fun details to existing projects.

You can map out different machining strategies within the software, from v-bit carving, drilling, 2D area clearing, inlays, and more, and select from a huge range of custom tools and machines, picking your speeds and feeds. Unlike V-Carve Desktop there’s no size limit for your creations (V-Carve Pro removes these limits), and when you’re done, simply export your design to your CNC controller software.

However, Carveco is only built for Windows, so Mac users will have to look elsewhere.

Free CNC Control Software

6. LinuxCNC – Best Free CNC Control Software

- Price: Free

- Compatible Hardware: CNCs with parallel porting control / LinuxCNC supported boards (General Mechatronics, Mesa, Motenc, Servo-to-Go)

- Operating Systems: Linux

- Where to get it: LinuxCNC

- Best for: DIYers parallel porting without a controller or running their CNC with LinuxCNC supported boards

Pros

Free and open-source.

Can control up to 9 axes of a CNC machine.

Highly customizable and supports many advanced control features.

Compatible with many popular machines.

Cons

A PC with real-time computing capabilities is needed.

Not beginner-friendly.

If you’re looking for free CNC control software and have compatible hardware, you can’t go wrong with Linux. However, note that LinuxCNC requires a special hardware setup and is not compatible with most commercial CNCs like X-Carve and Maslow.

This open-source software has been around since 1993 and is one of the most popular options amongst CNC hobbyists. Many later software, including the famous Mach series, had their original code based on LinuxCNC.

LinuxCNC can control up to 9 axes of a CNC machine and run mills, lathes, robot arms, laser cutters, plasma cutters, hexapods, 3D printers, and more. It has several different GUIs suited to particular types of usage, such as interactive development and touch screen. The software is also highly customizable and supports many advanced control features, including rigid tapping and cutter compensation.

You’ll need to have a PC with real-time communication like a parallel port or an ethernet to run LinuxCNC. This is because it runs under a Linux kernel with a real-time extension, allowing the software to generate the pulses required through a parallel port or a PCI/ISA card.

You can easily install the Linux CNC software on Debian and Ubuntu, or via Linux’s live/install DVD/USB images. Another benefit of using this software is that it has an active user community where you can engage with other Linux users.

It may seem intimidating to beginners due to its wide range of advanced features, but if you put the time into learning it, it’s a fantastic free software to use.

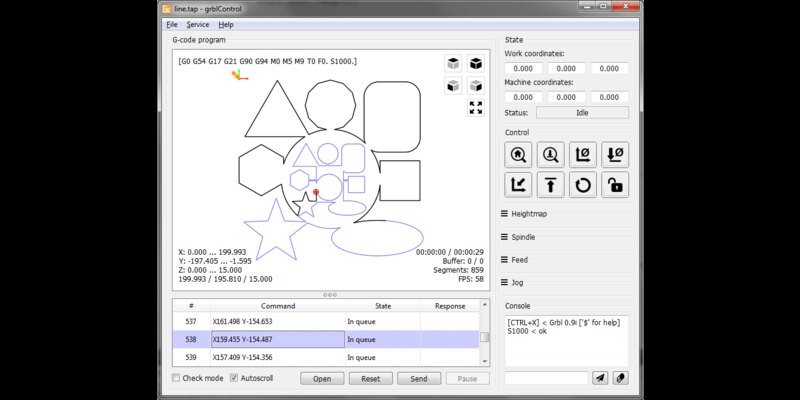

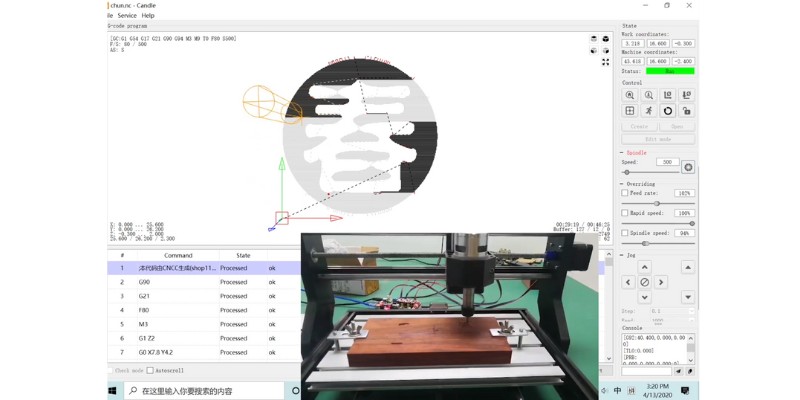

7. GRBL Candle – Powerful, Dependable Free CNC Software

- Price: Free

- Compatible Hardware: CNCs with GRBL controllers

- Operating Systems: Windows/Linux x86

- Where to get it: GRBL Candle

- Best for: Beginners following manufacturer’s instructions for starting projects

Pros

Free and used with some of the best GRBL-based CNC routers.

High quality and very dependable.

Easy and accessible for beginners.

Has many advanced parameters that make it suited for more experienced users.

Cons

Doesn’t offer backlash compensation.

Doesn’t support the rotation axis.

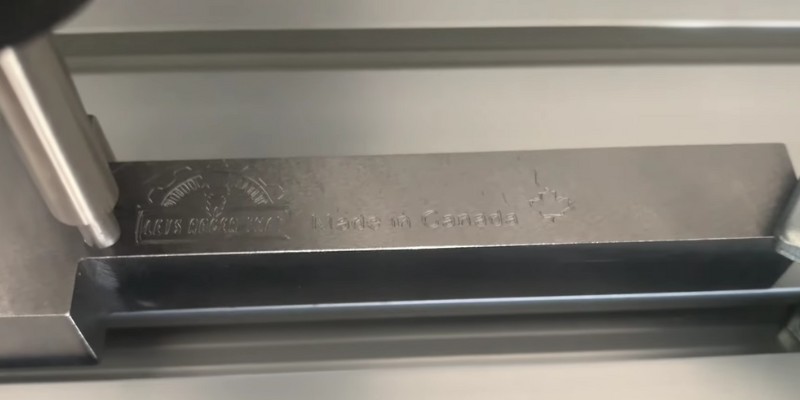

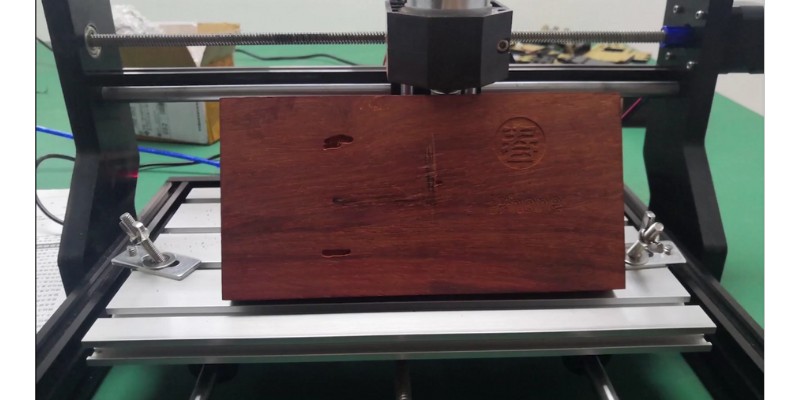

GRBL Candle is a free CNC control software that is used with some of the best GRBL-based CNC routers, such as the Sainsmart Genmitsu 3018 Pro and Vevor CNC routers. While it is fairly simple software, it’s still high quality and very dependable.

Candle ships with all popular basic DIY routers, such as 3018 CNC routers, as an easy and accessible CNC control software for beginners. It supports everything you need for creating your CNC projects, from loading, editing, and running g-codes on your router, as well as manual control to move coordinates / set zero coordinates.

GRBL isn’t just suited to beginners, though. This software also has many advanced parameters that make it suitable for more experienced users, so it’s a good software for growing your skills as a CNC machine operator. On the downside, it doesn’t offer backlash compensation and it doesn’t support rotation axis. Overall, it’s a great mini CNC router software option that’s simple and great for beginner CNCers.

8. Openbuilds Control

- Price: Free

- Compatible CNCs: those with GRBL controller

- Operating Systems: Windows / Mac / Linux

- Where to get it: Openbuilds Control

- Best for: CNC users with GRBL controllers

Pros

Lets you control your CNC router or machine.

Open-source and an intuitive UI.

Features live update visualizations of where your router is within the current job.

Also works with lasers, plasma cutters, and drag knife machines.

Cons

Bit of a learning curve for beginners.

Openbuilds, and the accompanying Openbuilds part store, form a one-stop shop for creative DIY projects, as well as a store that gives you the tools you need to build them. Spearheaded by Peter Van Der Walt, who also founded the LaserWeb laser software project, Openbuilds Control is compatible with Mac, Windows, and Linux, so if you’re looking for CNC software for Mac, Openbuilds Control could be for you.

Openbuilds Control lets you control your CNC router or machine, and also works with lasers, plasma cutters, and drag knife machines. It’s a great open-source CNC control software with a surprisingly intuitive UI, too, flattening the learning curve.

You can interface with your machine, run g-codes, set zero coordinates for your CNC router within the software, and it also connects with Openbuilds’ browser-based CAM software — Openbuilds CAM — for importing SVGs, DXF, and other files and converting them to g-code. It even features live update visualizations of where your router is within the current job in the CNC control software.

9. PlanetCNC – Free Software with G-code Manipulation

- Price: Free

- Compatible Hardware: CNCs with Planet CNC controller boards

- Operating Systems: Windows, Mac, Linux and Raspberry Pi

- Where to get it: PlanetCNC

- Best for: DIYers who want to install the Planet CNC controllers – DIYers upgrading their controllers for more axes

Pros

Comes with its own hardware.

Flexible configuration options.

Stable and robust.

Free to use.

Cons

Controller with a valid license is needed.

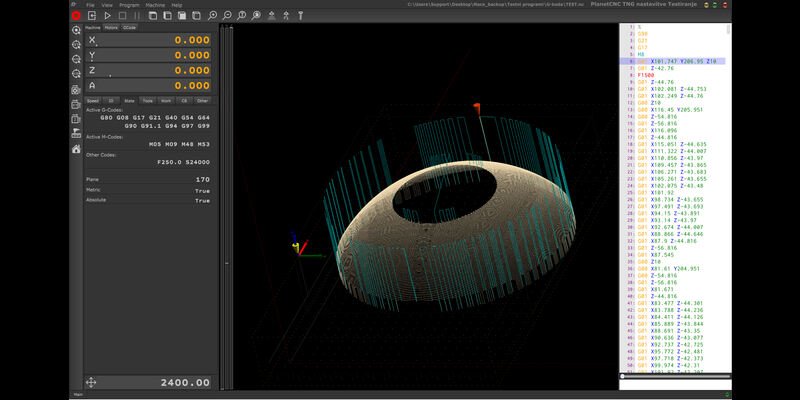

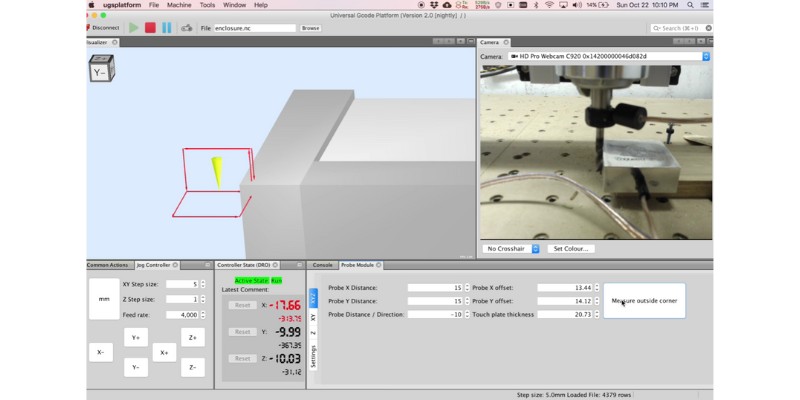

PlanetCNC is an excellent CNC router software that also comes with its own hardware. This software uses more modern techniques than some of the programs on this list, focusing on g-code manipulation. The software allows you to edit g-code and search for and bookmark lines of code. It also supports the copy and paste of g-code, allowing for fantastic flexibility.

One of the best things about this intuitive software is its flexible configuration options, with a fully-configurable tool change procedure, and simulation features. It supports many CNC machine uses, including spindle synchronization, probing, measuring, video display, relay control, and canned cycles. PlanetCNC software is also renowned for its stability and robustness.

PlanetCNC is free to use, but you’ll need to have a controller with a valid license. It’s compatible with Windows, Mac, Linux and Raspberry Pi operating systems and can import a wide range of file types, including Gerber, DXF, NC and PLT/HPGL. The transfer protocol is USB, which many users find much more comfortable than parallel ports.

PlanetCNC has an active user community and offers users great support. Another interesting aspect of this software is that it offers an API which allows users to create applications on top of it.

10. Universal Gcode Sender – Free CNC Software with G-code Manipulation

- Price: Free

- Compatible Hardware: GRBL, Smoothieware, TinyG, g2core controllers

- Operating Systems: Windows / Mac / Linux

- Where to get it: Universal Gcode Sender

- Best for: those with CNCs that have GRBL, TinyG, g2core, or smoothieware controller

Pros

Free and popular.

Easy to use with strong features.

User-friendly, making it a great choice for beginners.

Written in Java to support multiple operating systems.

Cons

You’ll need to pair this software with firmware that accepts g-code for your board.

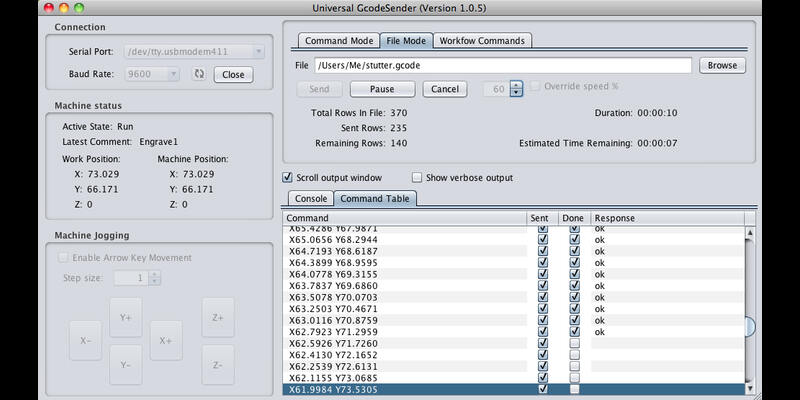

Universal Gcode Sender (UGS) is another free CNC control software option that’s become very popular due to its ease of use and strong features. This software has everything you’ll need as a CNC hobbyist and is particularly user-friendly, so it’s a good choice for beginners.

Some prefer UGS over GRBL Candle for the better control over individual axes on your CNC machine UGS offers. For example, UGS lets you control the Z-axis separately from the XY axes, so when moving axes you can set different movement values. This helps prevent accidentally jamming your router into the work area because you’ve set the XY axes to move greatly, and then accidentally clicked the Z-axis and the same amount of movement has occurred.

Useful features include executable all-in-one JAR files, a 3D g-code visualizer with coded line segments and real time tool position feedback, duration estimates, a web pendant interface, and more.

Another advantage of this software is its decent configurable G-code manipulation which allows you to remove comments, truncate decimal precision to configurable amounts, convert arcs to line segments, remove whitespaces and more.

UGS is written in Java to support multiple operating systems and is compatible with Windows, Mac, Linux (including ARM SBCs), and Raspberry Pi — making it popular for use with Arduino CNC routers. It also works well with custom setups. Bear in mind that you’ll need to pair this software with firmware that accepts g-code for your board.

Professional CNC Control Software

11. Mach4 – Overall Best CNC Software

- Price: $200 for Hobby version, $1,400 for Industrial version

- Operating Systems: Windows

- Where to get it: Mach4

Pros

Suitable for simple hobby machines and industrial CNC work.

Extremely intuitive that has customizable features and remote control options.

Can control up to 6 axes of a CNC machine.

Cons

No majpr drawbacks.

Developed by Newfangled Solutions, the Mach series is a leader in CNC software. Its latest offering is Mach4, a complete reboot of the popular Mach3 CNC software program. Whereas Mach3 was designed for simple hobby machines, Mach4 is suitable for industrial CNC work as well, with greatly improved speed and quality.

There are actually two versions of the software available – a hobby and an industrial version – with the latter costing significantly more. The industrial version includes advanced features such as Macro B G-code programming, tool life management, screw mapping, and an advanced GUI editing tool.

Mach4 is an extremely intuitive software that has customizable features and remote control options with quick and easy GUI customization. In the developer’s own words, it’s designed to be “expendable, flexible and extremely responsive for use with very large files”. The software has a modular architecture and allows for quicker development than Mach3 and other CNC controller software.

Mach4 uses “Motion Control”, whereby the core adapts to the motion of controllers attached, making for up to 100x faster response from button click to machine action and improved backlash control. Other useful features include improved anti-gouging, robotic loaders and asynchronous motion to control uncoordinated motion.

You can use Mach4 to control up to 6 axes of a CNC machine and run mills, drills, lathes, routers, tangenital knife, plasma, and 3D printers, among other machines. Each can be quickly and easily set up with the profiles and screens available in the Mach4 installer. The company is currently working on adding laser controls to the software.

Mach4 is a Windows-based software and is compatible with most Windows PCs. There’s a free demo version with up to 500 lines of G-code so that you can try out the software.

Read more: Mach3 vs GRBL (or Arduino vs parallel port)

CNC Simulator Software

If you’re looking for CNC simulator software, read our separate guide to each different CNC simulator.

How To Pick

Hardware Compatibility for Control Software

For CNC control software on lower-end CNCs, you have several choices. The most important factor is that the control software matches your CNC’s controller.

For example, with a GRBL controller, you can pick among UGS, OpenBuilds Control, Candle, and a lot more, but you can’t use LinuxCNC or Mach.

2D or 3D

Most beginners often only need 2D and 2.5D machining. These include cutting, engraving, pocketing, and more. But if you need more advanced machining, consider whether your software support 3D. For example, you can’t make 3D designs in Inkscape.

V-Carving

I find that engraving is a huge part of beginners’ projects. However, most often, they end up using a free software that doesn’t provide them full engraving capabilities. You’ll want a CAM software with v-carving to create fine engravings. For example, Easel’s paid version has v-carving, but the free version doesn’t support it.

Level of Expertise and Ease of Use

Some CAD software can be difficult to learn. You should choose a CAD software that’s only slightly beyond your needs and level of expertise, so you aren’t stuck unable to use anything too complicated for your level.

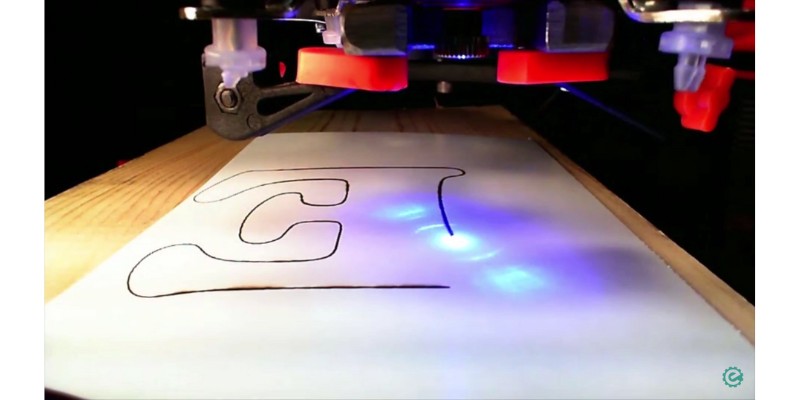

How CNC Software Works

The first step in the process is to create a design using CAD (computer-aided design software), which is separate to the CNC programming software. You can think of this as a blueprint for your design.

Anything you can design, you can make a reality with the right CNC design software, whether it’s a simple piece of woodwork or intricate, laser-cut fine jewelry.

You then need to use CAM software, which takes your CAD drawing file and creates a g-code. G-code is the most widely used CNC programming format and essentially provides information to the CNC machine about what work needs to be done.

The CNC control software is directly connected to the CNC controller with a transfer protocol, usually a parallel DB25 port or USB. The controller then directs the central breakout board which in turn sends instructions to the drivers, based on the information provided by the software. The drivers provide instructions to the motors, which control each axis to create models.

Once you have your g-code, you use your CNC controller software to run the machine and create your model from your chosen material.

Some software allow you to edit and input your g-code, known as g-code manipulation, while others – g-code sender software – simply send out the code to the firmware.

Find out which are the best nesting software that help you reduce material waste.

Other articles you may be interested in:

- The best CAD CAM software

- The best laser cutter and engraver software

- The best vinyl cutter software

- The best CNC routers

- The best CNC simulators

- How to make money with your CNC router

- Profitable CNC projects that sell

- AutoCAD vs SolidWorks: Comparison

- SolidWorks vs CATIA: Which is Best For Every Usecase

- Best Cabinet Design Software

- Ranking the best DIY CNC routers