With the best open-source CNC routers, you have the freedom to build your machine from the base up and customize it however you like.

These machines are able to deliver exceptional precision, versatility, and affordability by embracing the power of open-source technology.

However, choosing the right open-source CNC router can be tricky if you just jump into it. You need to find the right balance between what the machine is capable of, and your own technical experience to assemble and use it correctly.

For most users, I’d recommend an open-source kit from OpenBuilds for a reliable and easy-to-assemble solution.

The Lead 1010 is a powerful and versatile option that can handle most common materials, with customization options like control boxes and laser modules also available.

On the other hand, the Mini Mill is specifically designed for metalworking – cutting through tough material with stability and precision.

For users working on larger projects, the Maslow CNC stands out with its impressive 4ft x 8ft working area – with the bonus of an active and supportive community.

CNCSourced Recommends

- OpenBuilds Lead 1010 CNC Machine

- OpenBuilds Mini Mill

- Maslow CNC: Large Format DIY Wood CNC Router

- Shapeoko: One of the Original Open Source CNC Projects

- MPCNC: One of the Most Versatile and Affordable Homemade CNC Machines

Best Open Source CNC Routers & Machines Reviewed

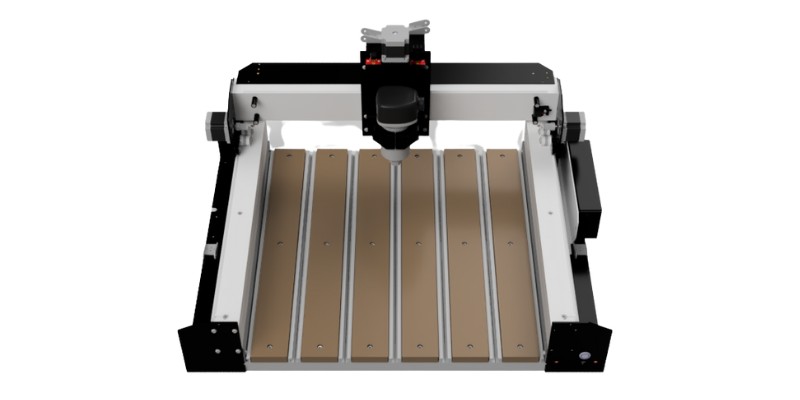

1. OpenBuilds Lead 1010 CNC Machine

- Price: Check at OpenBuilds here

- Assembly time: 2-4 hours

- Working area: 29” x 32” x 4”

Pros

Powerful and reliable build

Fairly quick to assemble

Comes with OpenBuilds software

Can add various components, including control box

Upgrade with an extension kit and laser modules

Other sizes available

Cons

Quite expensive for an open-source CNC

The OpenBuilds Lead 1010 is among the brand’s most popular open-source CNC kits. It’s a powerful and very rigid medium-sizes router that’s ideal for serious hobbyists and small business owners.

It’s capable of cutting and carving a wide variety of materials, including wood, acrylics, and non-ferrous metals. OpenBuilds software is included, with the option to include NEMA 23 stepper motors and other components like an OpenBuilds Black Box control system.

If you want to expand the 2” cutting height, there’s also an extension kit that gives you up to 8” of clearance. You can even add laser engraving components from brands like JTech Photonics and OptLasers. These lasers are specifically made to be compatible with the OpenBuilds Lead machines and are perfect for intricate etching on metals and other materials.

As well as the 1010, there’s also the OpenBuilds 15 15 open source CNC router. This has not only a significantly larger working area, but also improved stability thanks to the incorporation of an anti-whip adjustable tensioning system and other components.

One of the best things about OpenBuilds is that it also has a part store where you can easily source all the parts needed for building your CNC, as well as complete kits available to buy. This removes the hassle of sorting parts individually, often one of the main barriers facing DIY CNC enthusiasts.

2. OpenBuilds Mini Mill

- Price: Check at OpenBuilds here

- Assembly time: 2-4 hours

- Working area: 4.5” x 7” x 3”

Pros

Great for metal work

Based on very solid structure and component

Beginner-friendly

Can order just base or full kit

Other community builds available

If you’re looking to work with metals, you’ll need a mill rather than a woodworking CNC router. The OpenBuilds Mini Mill is a great open-source option.

This is a high-quality and compact open-source CNC mill for intricate carving and engraving. It boasts a solid C-beam structure, high-resistance wheels, and lead screw actuators for top-of-the-range stability. All this, in a beginner-friendly package that takes just a few hours to put together.

The price we’re quoted is just for the base kit, but there’s also the option to add a control system, NEMA 23 stepper motors, a milling component, probe, and power supply. Alternatively, you can source your own parts depending on your preferences.

There are several open-source mills from OpenBuilds community members, too. The C-beam Mini Mite costs about $87 extra for the base kit but offers around three times the build volume.

On OpenBuilds, all the community builds are rated by other users, so you don’t need to waste time experimenting with a homemade CNC router plan if it hasn’t got good reviews. You can also engage with other community members through the OpenBuilds forums.

3. Maslow CNC – Large Format DIY Wood CNC Router

- Price: Check latest price at MakerMade here / Amazon here

- Assembly time: At least 6 hours

- Working area: 4ft x 8ft

Pros

Large 4ft x 8ft working area

Far cheaper than most similar-sized machines

Fairly large user community

Free design files available for Maslow projects

Can also download files for upgrade components

Cons

Tricky to assemble with the need to build such a large frame

The Maslow CNC is one of the most popular and unique open-source CNC router machines out there, largely because it’s probably the biggest. It’s a fairly unusual-looking CNC machine, with an upright frame and a sled suspended on a chain system that relies on chain tension and gravity for movement.

With a huge 4ft x 8ft working area, the Maslow CNC makes large format CNC technology available to everyone. Hobbyists have created all sorts of projects with the Maslow, ranging from home furniture and sheds to signs and even boats.

One of the main benefits of the Maslow is that, with kits starting from $439, it costs just a fraction of what similarly sized commercial machines retail for.

You can purchase a kit from the Community Garden, or an upgraded, improved version from Maker Made. While each Maslow has the same basic design, the hardware varies between some kits. Another nice aspect of the community garden is that many hobbyists have uploaded design files for Maslow projects they’ve created that you can download for free.

Alternatively, you can use the documentation available on the Maslow Github to build it from scratch. From here, you can download everything you need, including the WebControl controller software, the Maslow firmware, and the Maslow PCB design.

If you’re a fan of using DIY CNC router build plans, Community members have also added design files for many other upgrade components and accessories over the years, such as Z-axis mods, chain guides, a drill depth equalizer, a dust collector, and much more.

One thing to bear in mind about this 4ft x 8ft CNC router is that you will have to construct your own frame for it. Again, the design files are available on the Maslow site, but you are going to need to source the material and build the frame yourself, which can take some time, particularly if you’re not experienced in woodworking.

If you like the look of the Maslow, it’s worth also checking out the MakerMade M2. This is essentially the upgraded version of the Maslow CNC, and is a more traditional commercial machine, rather than being open source. However, it’s still the same size and design as the Maslow, and at $1,198, is still far cheaper than virtually all other large-format CNC machines.

The M2 delivers improved performance compared to the Maslow, with an improved control board, up to 40% faster cutting, smoother movement, increased chain tension, and the ability to add a laser module.

While the M2 isn’t completely open source like the Maslow, it still uses an open-source software called Makerverse which can also be used to control other CNC machines and 3D printers.

4. OpenBuilds CNC Lathes

CNC lathes are preferred over routers and mills for working on cylindrical objects. OpenBuilds doesn’t offer its own lathe, but there are lots of community lathe builds available on the site.

Pros

Wide variety of lathe builds to choose from

Various sizes available

Parts can be directly bought from OpenBuilds

Cons

Some builds are quite complex

Several of these open-source CNC lathes have 5-star ratings. These include:

Each of these builds comes with complete documentation, with most parts available to buy directly on OpenBuilds and from other retailers, as explained in their documentation.

5. Shapeoko – One of the Original Open Source CNC Projects

- Price: ~$300

- Assembly time: 2-3 hours

Pros

Very affordable

Beginner-friendly and easy to assemble

Desktop CNC for small home projects

Github files available for the upgraded version

Cons

Limited working area and cutting power

You may well be familiar with the name Shapeoko, as it’s one of the most popular hobbyist CNC router ranges, the latest model being the Shapeoko 4. However, what you may not know is that the Shapeoko line actually started out as an open-source CNC machine over a decade ago.

The ShapeOko, as the name was originally stylized, was created as a simple open-source project that allowed people to get into CNC work without breaking the bank. It was a 3-axis CNC router build specifically aimed at beginners, and was designed to make assembly as easy as possible.

The parts needed were valued at around $300 back then, with the low price attracting a lot of interest in the days before low-cost CNCs from countries like China exploded on sites like Amazon. The Kickstarter project was a huge success, raising over $11,000 from 125 backers and far exceeding the $1,500 target.

While the Shapeoko line has come a long way since, becoming some of the most popular CNC routers, you can still download all the original open-source CNC plans from Github.

Following the original ShapeOko’s success, creator Edward Ford created the ShapeOko 2 shortly after (this was the last open source model before the range transitioned to commercial machines). The full documentation for this improved version is still available on the Shapeoko Github if you want to try your hand at building a ShapeOko 2.

Now, the Shapeoko CNCs are closed-source, with Edward Ford still serving as VP at the since-formed company Carbide 3D. You can buy the Shapeoko 4 range, but the designs are no longer open source. I’ll link to the CNC below:

The Shapeoko models feature Carbide's Sweepy V2 dust collecting system, which consists of 6 fiber-reinforced nylon clamps.

6. MPCNC – One of the Most Versatile and Affordable Homemade CNC Machines

- Price: from $232.99

- Working areas: up to 48” total X & Y axis dimensions

- Assembly time: 3-4 hours if buying parts, 3D printing takes longer

Pros

Highly configurable open-source CNC router

Can 3D print your own parts

Frame can be used for routers, mills, and 3D printers

Low cost

Active community with continual improvements

Cons

Not ideal if you’re not experienced with 3D printing

The Mostly Printed CNC is, as the name suggests, an open-source machine made from (mostly) 3D printed parts. This evolved from the RepRap project, a project to develop the first-ever self-replicating 3D printer, started by Dr Adrian Bowyer at Bath University in the early 200s.

The base MPCNC kit is most commonly used to build a CNC router, but it can also be used to create a 3D printer, mill, laser cutter, or vinyl cutter, as explained in the community forum.

This DIY CNC router plan is notable for being one of the cheapest CNCs out there. You can get the build kit with the hardware, electronics, and control board for $232.99, and then you just need the conduit and 3D printed parts. In total, the cost estimate is $465 if you have a 3D printer already, and $595 if you buy the 3D printed parts.

Another great thing about this open-source CNC machine plan is its flexibility. You can decide the axis length (the base kit has enough belt for up to 48” total X and Y axis dimensions), although bear in mind the smaller you make it, the faster, more rigid, and more accurate it will be.

Following several improvements and contributions from community members, the MPCNC Primo is the most recent version. It has a super sturdy frame, a powerful motion system for improved precision, and is one of the best open source CNCs for customization.

What Makes a CNC Router Open Source?

A CNC router is open source if every aspect of its construction is documented and freely available. This includes the build plan, part list and cost, and the circuitry, firmware, and hardware design. Nothing is gatekept or behind a paywall.

This doesn’t mean companies don’t charge for the kits, however. Companies in CNC often sell the parts as a kit at a profit, to save you time sourcing the myriad parts yourself.

Similarly in 3D printing, the Prusa i3 MK3S+ is built off of the original RepRap i3 open source plans and is a completely open-source machine, yet the Prusa Research company does over $70M in revenue yearly.

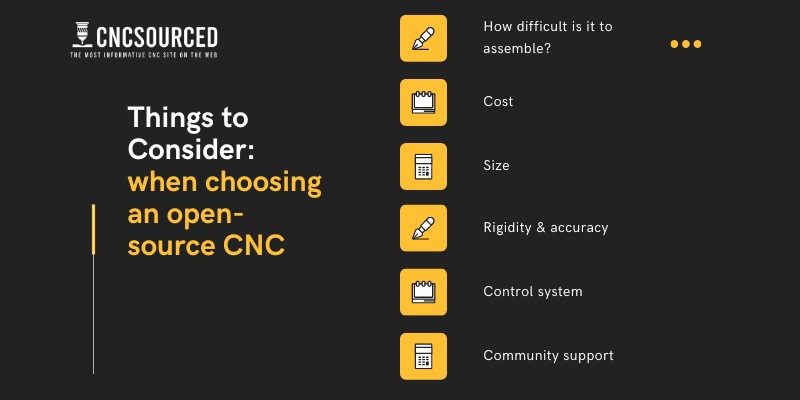

Factors To Consider When Picking An Open-Source CNC

How difficult is it to assemble?

Perhaps the most crucial consideration when looking at open-source CNC router plans is how difficult the build will be. This can vary, from relatively simple builds like the OpenBuilds 1010 to more demanding and time-consuming constructions like the Maslow.

| CNC Router | Assembly Time |

|---|---|

| OpenBuilds Lead 1010 | 2-4 hours |

| OpenBuilds Mini Mill | 2-4 hours |

| Maslow CNC | At least 6 hours |

| Shapeoko | 2-3 hours |

| MPCNC | 3-4 hours (parts) |

It’s also important to consider the difficulty of sourcing the parts, particularly if you’re using an older plan. This is why many DIYers head to the OpenBuilds part store, where you can easily source the parts needed for the machines featured on the site.

Cost

Open-source CNC routers can vary quite a lot in terms of cost. For example, the Maslow CNC and MPCNC routers can be built for around $500, while some of the premium models from the likes of OpenBuilds are a fair bit more expensive.

It’s also important to consider the longer-term maintenance costs of a DIY CNC router. For example, if you’re considering spending around $500 on the Maslow, it may be worth spending a few hundred dollars extra and getting an upgraded (but not open-source) version in the MakerMade M2.

Size

Home-built CNC routers come in all shapes and sizes, from tiny desktop machines to large format routers like the Maslow CNC.

The CNC router’s size determines the size of the workpieces you can cut and what projects you make, and it also impacts how easy it is to build and operate your router.

For example, the 4ft x 8ft footprint of the Maslow CNC is more difficult to assemble and requires a much larger storage/working space than a smaller router, but it also allows you to work on much bigger projects such as CNC cutting signs and sign-making.

| CNC Router | Working Area |

|---|---|

| OpenBuilds Lead 1010 | 29” x 32” x 4” |

| OpenBuilds Mini Mill | 4.5” x 7” x 3” |

| Maslow CNC | 4ft x 8ft |

| MPCNC | Up to 48” total |

Rigidity & accuracy

It’s important to make sure that an open-source CNC router offers the performance you need before you start sourcing parts, or you’ll end up wasting time and money. The best way to do this is to read the documentation in full, see what other users say, and carefully consider the effects of any modifications you make.

For example, you can determine the length of MPCNC axes, but a build with a smaller footprint will provide more stability and accuracy. OpenBuilds plans are reliable, and you can also check out what other users have to say about community builds before jumping in.

Control system

A big consideration to make when building an open source software is the controller and software you use. Many hobbyists like to use GRBL software and controllers, which are free and open-source.

You can build your own CNC controller from scratch, but bear in mind this is a complex process that will require some learning if you’re newer to CNC.

Community support

The importance of having a large and active user community to lean on should NOT be underestimated, as your fellow hobbyists are your best bet WHEN (not if) you run into any issues.

This is one of the main reasons OpenBuilds stands out for open source and DIY CNC projects, with a wide variety of peer-reviewed community builds, as well as the chance to engage with other CNC’ers in numerous forums.

Are there any other open source machines?

Yes, there are a variety of other CNC machines that are open source. For example there are DIY laser cutter kits you can build, and a number of the best open source 3D printers are widely sold best sellers, including those by Prusa, BCN3D, and others.

There are also a range of open source DIY 3D scanners you can build cheaply from scratch, such as the BQ Ciclop and other projects once you’re ready to expand beyond the best open-source CNC routers.

FAQs

Is Maslow CNC open source?

Yes, the Maslow CNC is open-source. It’s a large 4×8 foot CNC router, and you can download the documentation files and build it yourself, or purchase complete Maslow kits from the website.

Is Shapeoko open source?

The original two Shapeokos (then stylized as ShapeOko), were both open-source machines that started through a Kickstarter campaign. The Shapeoko 3 and 4 that followed are commercial machines that aren’t open source, sold by Carbide 3D.

Is GRBL open source?

Yes, GRBL is a completely free and open source software for controlling CNC machines.