Fiber laser engravers are best for metal engraving – CO2 lasers and diodes struggle to mark metal as metal is such a reflecting surface. But, newer 1064nm infrared lasers on diode engravers can mark metals quite effectively, and CO2 lasers can also engrave metals under the right conditions.

The best low-cost fiber laser is the Ten-High 20W fiber laser. If you have the budget, get a 30-50W (ideally 50W), but this 20W laser is one of the most affordable around that still does a good job engraving metals.

I recommend the xTool F1 as the best diode laser for metal engraving. It comes with a 2W IR 1064nm laser which I’ve used to quickly create accurate and intricate jewelry designs on pendants and dog tags. If you need a larger working area, get the xTool D1 Pro and the 1064nm accessory.

If you’re looking for a CO2 laser, I recommend the xTool P2. It’s powerful with 55W power, the fastest dekstop CO2 laser that can engrave metal at up to 600mm/s, and has batch processing features and simple rotary engraving for all types of metal engraving.

|

CNCSourced Rating: |

CNCSourced Rating: |

|

4.7

|

4.8

|

|

Laser type:

Diode

|

Laser type:

Diode and Infrared

|

|

Laser Power:

10W/20W/40W

|

Laser Power:

10W & 2W

|

|

$629.99

|

$1799

|

How We Picked

This hands-on guide will share everything you need to know about the best metal laser engravers, comparing them across:

- accuracy and precision

- ease-of-use

- power

- value for money

And any unexpected surprises my tests revealed. I’ve added images of the tests I ran on lasers such as the xTool D1, F1, and P2 so you can see how these projects came out.

(For non-metal laser cutting and engraving, we also have a general ranking on the best laser cutters and engravers)

CNCSourced Recommends

Budget metal laser engravers for hobbyists:

- xTool D1 Pro: TOP PICK UNDER $1000 and great for coated metals

- xTool F1: Best portable laser engraver for metal

Professional metal laser engravers for small businesses:

- xTool P2: Best CO2 laser for metal

- Ten-High Fiber Laser Engraver: Fiber laser top pick

The Best Laser Engravers For Metal Ranked

1. xTool F1 – Best Portable Laser For Metal

- Price: Check latest price at xTool here / Check latest price at Amazon here

- Working area size: 115 x 115mm

- Laser power: 10W & 2W

- Laser type: diode and infrared

- Weight: 4.6kg

- Engravable materials: wood, acrylic, leather, rubber, card, plastic, glass, stone, ceramic metals

One of the problems with metal laser engravers is that affordable diode lasers can only engrave coated metals, and desktop models with infrared or fiber lasers are typically very expensive.

However, the xTool F1 is a diode laser that also includes an infrared laser for engraving both ferrous and non-ferrous metals at an affordable price.

However, it’s very small, with just a 115 x 115 mm working area, so you can’t work on large projects. But, it’s a great option for jewelry engraving and other small metal projects. You can also extend the working area to 400 x 115 mm with the Slide Extension accessory.

I tested the 2W infrared module as part of my xTool F1 review on both metal business cards and jewelry necklace dog tags. On all my tests, the engravings were sharp and accurate – the designs really were clean and crisp, and took less than a minute to engrave. This makes it ideal if you’re selling custom jewelry with peoples’ names, or designs of their pets, at local trade shows.

While you can use this at home as an alternative to more expensive desktop models, the F1 is also specifically designed for use at trade shows. Its small size and light weight make it highly portable, and it has an incredible engraving speed of up to 4,000 mm/s, to finish projects in minutes and make more money.

The F1 doesn’t have enough power to cut metal, but it’s fantastic for engraving projects. It also has a 10W diode laser for increased versatility when working with other materials.

It's portable and easy to carry to craft and trade shows, and it's the best laser for on-demand custom laser engraving overall. No laser matches its 4000mm/s speed, and the IR laser makes metal engraving a breeze. I highly recommend the xTool F1.

- Super fast

- Portable - weighs 10lbs

- Versatile - diode and IR laser

- Small working area

- High price

2. Ten-High Fiber Laser Engraving Machine for Metal – Best For Small Businesses

- Price: Check price at Amazon here

- Laser power: 20W

- Work Area: 110×110mm

- Laser Type: Fiber

Pros

Powerful metal laser engraver.

Can be used for a variety of different metals including stainless steel.

Extremely precise.

The marking is noticeably clear, firm, and permanent.

Cons

Too advanced for beginners.

This is a very powerful metal laser engraver that’s an excellent choice for professional metal workers.

You can use the Ten-High Fiber Laser Engraving Machine with a variety of different metals including stainless steel. It’s also suitable for working with some non-metallic materials, including aluminum oxide, electroplating material, and industrial ceramics.

Thanks to the high-grade fiber laser equipped with an optical insulator, this metal laser cutter is also ideal for working with gold, silver, copper, and aluminum. You can regulate by frequency and energy for working with different metals.

This laser engraving machine for metal is extremely precise. In fact, its marking speed is 3-5 times faster than regular YAG and DP semiconductor engravers. You can also control the marking depth for improved accuracy.

The marking is noticeably clear, firm, and permanent. This is due to the minimum spot diameter of up to 0.1mm, meaning it can be used for micro painting, bar codes, and trademark marketing.

The operating table and the integrated design structure makes for comfortable and convenient operation, so this machine is nice to work with. The optical path of the laser also has a new sealing system that prevents optical pollution.

3. xTool D1 Pro – Best Diode Laser For Metal Engraving

- Price: $699 — Available at xTool here

- Laser power: 10W (5W, 20W and 40W also available)

- Work area: 432 x 406 mm

- Laser Type: Diode

Pros

One of the best diode lasers available.

Can mark and engrave on coated metals, especially if you buy the infrared laser add-on.

Accurate, reliable, and sturdy.

Cons

Diode lasers are still very limited for metal engraving, and you can only etch on coated metals like anodized aluminum.

The xTool D1 10W is the best diode laser in my opinion, slightly beating the Ortur Laser Master 3 which I also own. The xTool has a better-quality steel frame, versus a cheaper rotary roller and better safety features on the Ortur.

You can stick with the standard 10W laser (which xTool say is the equivalent of other brands’ 15W lasers), or upgrade to the 20W model for more power.

While you’ll need a fiber laser to really effectively mark metals, more powerful diode lasers such as the xTool D1 Pro can mark coated metals: stainless steel, anodized aluminum and similar can all be engraved on.

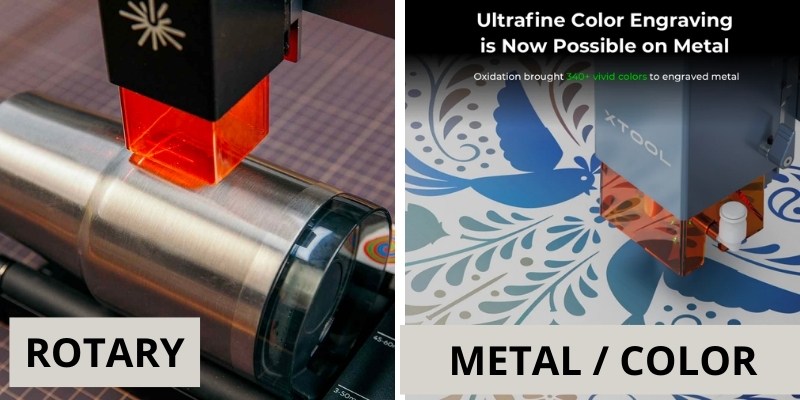

I recommend two accessories for this: the infrared laser attachment, and the RA2 Pro rotary chuck. With these, you can better engrave metals, and engrave rounded metal objects like beakers, flasks, and more. You can also read my full review of the xTool D1 Pro 20W.

Other variations available include:

- xTool D1 Pro 5W — Available at xTool store here

- xTool D1 Pro 20W — Available at xTool store here

- xTool D1 Pro 40W — Available at xTool store here

The work area is large, and you can buy the extension kit that increases your work area to an incredible 936 x 432 mm.

It’s accurate (0.01mm precision, 0.08 x 0.06 mm spot size), reliable with the sturdy frame and steel wheels and rods and protected belts, and safe. The software that comes with the xTool is also really user-friendly, or you can use it with LightBurn instead. There’s the Laserbox iOS app for connecting via iPad or similar device.

Other makers online have shown the xTool’s effectiveness for engraving anodized aluminum, and while if you can afford a fiber laser (we recommend them further in this article) you should opt for one, if you’re looking to save money or buy a diode laser, this is up there for the best.

And if you need even more power, go for the 20W version (we did!)

4. xTool P2 – Best Desktop CO2 Laser Engraver For Metal Projects

- Price: Check latest price at xTool here

- Working area: 600 x 308 mm (24″ x 12″)

- Laser type: CO2

- Power: 55W

Pros

Highest-power 55W laser in its price range.

Ideal for engraving metal objects, and cylindrical shapes with the rotary.

Fast 600mm/s max speed.

Cons

Metal materials are expensive in the xTool store. It’s best to buy from elsewhere.

It’s the fastest desktop metal laser engraver in its price range. No other CO2 or diode laser can mark metals as fast as the xTool P2, which vector engraves metal at 600mm/s. This is ideal for small businesses looking to get through many projects quickly to sell.

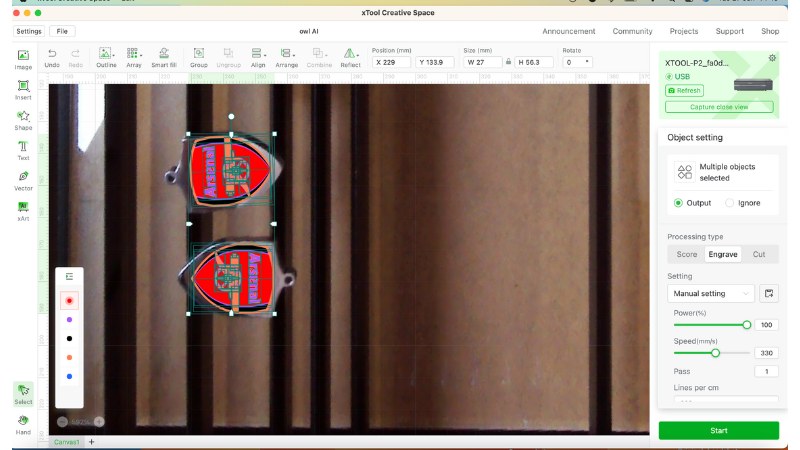

The batch processing features were the most impressive feature during my testing for my xTool P2 review. If you align your design on one metal object in your working area, and click the “Smart Fill” button, XCS software will automatically align your design with any other objects in exactly the same way.

This is a huge time-saver, especially with intricate, precise metal jewelry where perfect alignment can take time.

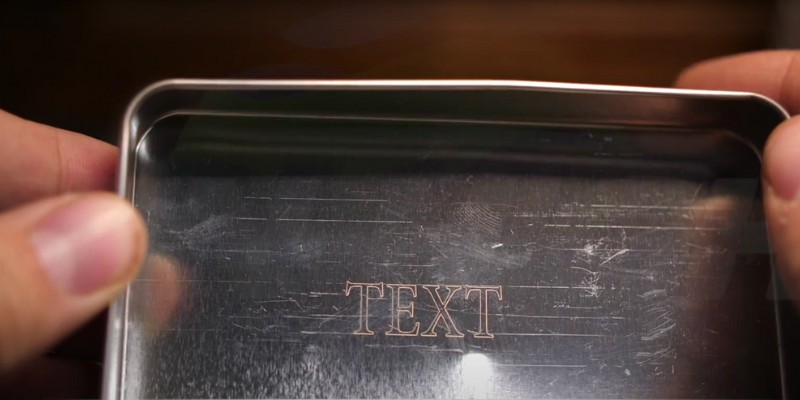

You can see an example I tried on two reflective metal stainless steel necklace dogtags below:

The P2 can create darker etchings or just lightly frost the surface – perfect for jewelry, knives, trophies, and custom metal parts.

Dual auto-focus cameras make setup easy, and if you have any uneven surface metal parts, or curved surfaces like spoons, the curved surface engraving features automatically adjust to this so your design comes out perfectly and doesn’t distort.

This is possible as the cameras act as depth sensors, and create a similar style 3D mesh to a 3D scanner, and then the laser can adjust the design based on the height at each part of your workpiece. For more information, here’s my video on how this works with the xTool P2:

For professional-quality metal engraving, the xTool P2’s 55W CO2 laser has the power to mark coated metals such as stainless steel, aluminum, brass, and more.

The large 24″ x 12″ work area accommodates oversized plates or batches of smaller pieces, though if you’re engraving metal jewelry, you may not need something so large.

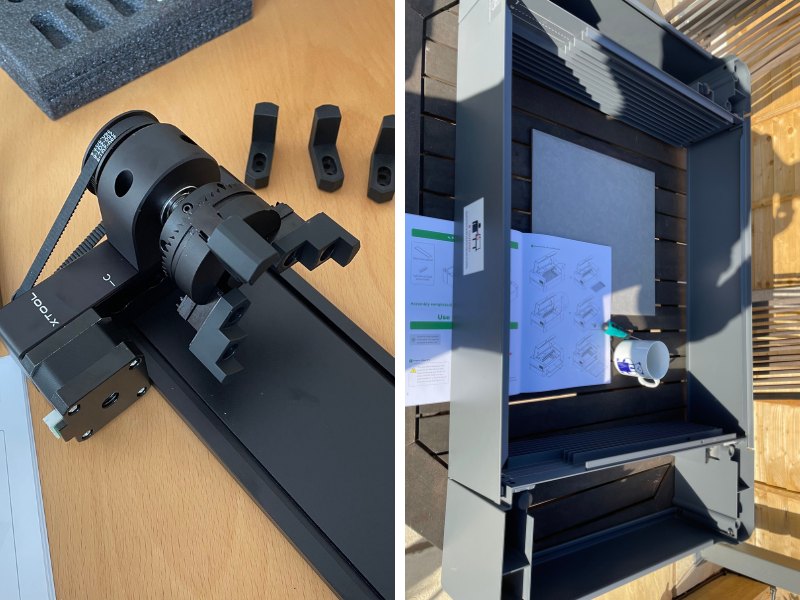

The xTool P2 comes with 2.5” of max height, so I recommend getting the riser base accessory, along with the RA2 rotary for engraving metal beakers, flasks, and other cylindrical metal objects.

The riser base gives you a maximum 8.5” height so you’ll be able to rotary engrave anything you want, as well as laser cut large material sheets if you’re also planning on acrylic or wood projects.

Though the spot size is larger than for example the xTool D1 Pro (the P2 has 0.15×0.2mm), this is still very precise. For example, here’s a couple of slate coasters I tried where you can see just how precise and intricate the laser was able to mark:

Overall, I think it’s the best desktop CO2 laser right now, and the best CO2 pick for stainless steel and aluminum engraving.

Batch processing features help streamline engraving multiple metal tags, plates, or parts in a single session. And the advanced software automatically adjusts for curved surfaces.

How Metal Laser Engraving Works

Metal laser engravers work by projecting highly concentrated laser beams onto metal surfaces. The laser essentially vaporizes the metal surface, leaving a permanent crevice. This requires a lot of energy – a vaporization temperature of 2,327 degrees is needed to engrave aluminum, for example – so laser engravers are powerful tools.

However, there are less drastic ways of marking metal with a laser, allowing for more affordable laser engravers to be of use.

Laser marking and etching are two other uses (more info on the differences further on). For a clear, deep engraving, you’ll need a more powerful CO2 or fiber laser engraving machine, but for light marking of metal, we recommend lasers in the $400-700 price range that have been proven to work, but at lower quality and power.

Metal Laser Engraving Uses

More powerful metal laser engravers can work on all sorts of different metals, from aluminum and steel to magnesium and lead.

Laser engravers are important tools for many industries for:

- Barcodes

- Serial numbers

- Logos

- Tracking numbers

These products can range from everything from machines, hardware, and automobile parts, to measuring tools and medical devices

Laser Etching vs Laser Engraving vs Laser Marking Metal

Metal Laser Etching

Laser etching changes the metal’s surface color via a very thin surface depth change — usually no more than 0.02mm. The laser melts a very small amount of the surface material, or reacts to the metal’s surface, leaving a raised area that contrasts with the untouched material. Metals like stainless steel, aluminum, and copper and commonly laser etched.

There are specialist sprays for laser etching materials, such as CerMark marking solution, designed especially for creating black marks on metals that contrast for barcodes, serial numbers, logos, and other uses. Laser etching metals also has applications in precious metal jewelry.

Etching is the easiest metal laser engraving process for hobbyist home laser engravers, and makers have found ways to etch using mustard, vinegar, and other homemade solutions.

Metal Laser Marking

Laser marking involves oxidizing material underneath the material’s surface to turn the marked areas black and contrast with the rest of the metal. While engraving and etching affect the material’s surface, laser marking affects only below-surface areas, so the material’s texture remains unaffected.

Like etching, laser marking is used for logos, but is also used for medical parts and in the automotive industry.

Metal Laser Engraving

Engraving metals typically involves cutting up to a 0.125” deep recess physically cut into during the engraving process. This is the deepest cut of the three processes and creates a contrasting design that is useful for logos and traceability.

High-quality professional metal laser engravers can work quicker than markers or etchers, and are often used for processing stainless steel parts, as well as with alloys and other metals.

Which Metals Can You Laser Engrave?

Aluminum

Aluminum can be engraved and etched using CO2 or fiber engraving machines for clean results. The laser exposes the bright substrate of the material, with black anodized aluminum producing the most contrasting results.

Aluminum is used for crankcases, crankcase covers, and automobile aesthetic body parts, as well as custom business supplies like branded pens, flasks, metal business cards, and more. We also have a guide to laser engraving anodized aluminum.

Stainless Steel

Laser marking stainless steel creates high contrasts, and it can also be laser engraved. Stainless steel 316 and 306 are most common types. Stainless steel is a popular metal for budget laser engravers, and we’ve previously shown videos from makers who have marked stainless steel with engravers such as the Ortur Laser Master 2 Pro.

Stainless steel engraving is used for aesthetic parts, fuel tanks, railings, and suspensions. You can even create color markings on stainless steel with a color laser marking machine. If the differences aren’t clear, we’ve also written on the difference between laser marking, etching and engraving.

Steel

Steel can also be laser engraved, though its toughness makes it far more difficult, requiring longer engraving times to create adequate surface contrast.

Though, compromising color/contrast of the engraving can lead to faster engraving speeds. Generally, higher engraving speeds create white marks, and slow speeds mark it black.

Brass and Copper

Fiber lasers can mark and engrave on metals like brass and copper, with uses in musical instruments, jewelry, plumbing, tubing and pipes, nuts and bolts, and many electronics.

Copper is a soft metal that conducts heat well, and isn’t too difficult to engrave. You can etch brass and create dark marks due to its low melting point and high thermal and electric conductivity.

You can read more about copper and brass engraving here.

Titanium

Titanium can be marked, etched and engraved. Frequently used in jewelry, laser engraving services let you engrave a name, date, fingerprint, symbol, or any other sentimental design onto jewelry via metal laser engraving.

Fiber lasers can engrave on titanium sheets for uses such as in attractive metal sign creation for small businesses, with a good example shown below:

Gold & Silver — Laser Engraving Precious Metals

Yes, you can even laser engrave gold. Laser engraving has sentimental uses in precious metal engraving for jewelry, such as gold, platinum or silver jewelry.

This jeweler has even laser engraved a QR code into gold that takes you directly to their YouTube channel. You also lose so little of the material during engraving that even on expensive metals like gold, the weight lost to engraving is insignificant.

Types of Laser Engraver For Metal

CO2 Lasers

CO2 metal laser engraving machines use a gaseous mix of CO2 which undergoes electrical treatment to produce the laser beam.

These machines use a roughly 10.6-micron CO2 laser beam wavelength, and can also engrave other non-metal materials such as woods, plastics, leather, and more. They can’t cut metals (unless you have an extremely powerful 150W+ industrial machine), but they can engrave metals like anodized aluminum and other coated metals.

Fiber Lasers

Fiber laser engraving machines have a smaller 1.06-micron wavelength. They’re generally considrered faster than CO2 lasers, and with fiberoptic cables can intensify the laser beam’s strength for a more effective use of their power. Fiber lasers’ high power, small wavelengths and small focal diameters make them well suited to engraving metal.

50W laser engravers are considered high-power fiber laser marking machines. They’re also reliable, with long service lives.

Crystal / Diode Lasers

Crystal lasers can be considered similar to fiber lasers, and also belong to the same class of solid-state lasers. They’re often used in affordable laser engravers like the Ortur Laser Master range, and are ideal for plastics, woods, ceramics — and can engrave metals if coated. They use diodes to engrave, and their light weight and small size make them ideal for desktop engraving.

Metal Laser Engraver & Cutter Alternatives

As well as engraving and cutting metals with a laser, you can also opt for a CNC router or milling machine.

You can read our guides for these below:

Other laser buyer’s guides:

- Best Jewelry Laser Engraver

- Best Laser Engraver For Leather

- Laser engraving machines for glass

- Best wood laser engraver

- Best acrylic laser engravers

- Best inexpensive laser engravers

- Best Laser Engravers for Tumblers & Yeti Cups

Other laser guides:

- Laser etching metal: complete guide

- Color laser engraving guide

- Complete laser cutter materials guide