Key Takeaways

- Anodized Aluminum: Anodized aluminum is a durable and colorful metal that can be laser engraved or etched.

- Laser Engraving: Laser engraving removes the anodized layer and creates high-contrast marks on the bare aluminum.

- Laser Etching: Laser etching changes the color of the anodized layer and retains its resistance to corrosion and abrasion.

- Laser Types: Diode, CO2, and fiber lasers can all work on anodized aluminum, but with different speed and quality.

Are you looking to add a touch of personalization and durability to your aluminum products?

Laser engraving and etching on anodized aluminum will provide you a colorful surface with a smooth metallic shine – and long-lasting durability.

This complete guide will explain how to engrave or etch anodized aluminum, tips and tricks based on anodized aluminum’s traits, and the quality of its engraving marks.

Most lasers can engrave anodized aluminum – but different types of lasers are able to engrave faster and obtain better results. I’ll cover the different laser options I’ve tested and explain the differences so you can choose the one that’s right for you.

Can You Laser Engrave Anodized Aluminum?

Yes, you can engrave and etch anodized aluminum. Laser engraving anodized aluminum is great for art designs since it’s still pretty durable.

However, laser etching is more common than laser engraving in manufacturing, since laser etching retains the anodized layer’s resistance to abrasion and corrosion.

It’s great for engraving because it comes in many colors, as well as its accessibility – even diode lasers can engrave anodized aluminum and create high-contrast engravings, though you’ll still get the best results from more powerful lasers.

Here are some reasons why anodized aluminum is an ideal metal to engrave:

Robustness

Anodized aluminum doesn’t rust and resists abrasion, making engraving anodized aluminum one of the best materials for laser projects for your home and in industry.

The anodized layer has already reacted with oxygen, protecting the metal from further oxidation.

Plus, the anodized veneer is extremely tough, and resists scratches much better than bare aluminum.

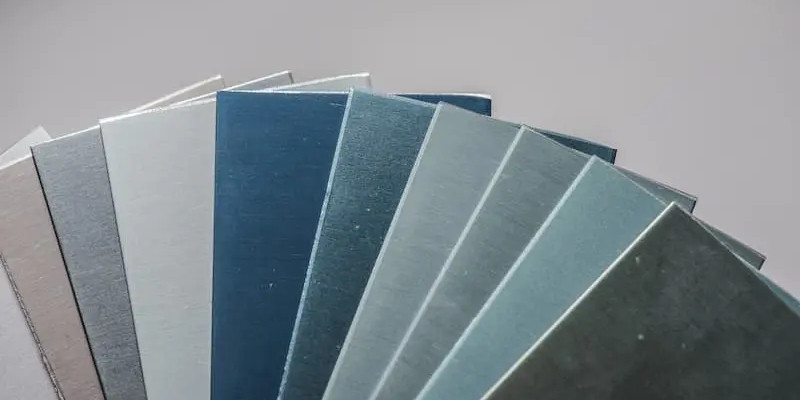

Color

Anodized aluminum comes in various colors, offering more design flexibility. For example, you can buy yellow-ish sheets to create high-contrast yellow pet tags. You can bump the contrast up further by engraving on painted anodized aluminum.

Many materials don’t yield high-contrast engravings. For example, laser engraving wood or steel generates a much lower contrast than anodized aluminum.

Anodized aluminum’s color is not a mere paint that lays separately on the surface and peels off easily. Its surface has countless micro pores that stand like tough straws, so the color dye infiltrates the pores.

Therefore, you can’t scratch the paint off anodized aluminum easily.

However, laser engraving removes the anodized layer, causing the contrasting aluminum color to shine via the engraving.

Laser etching also creates a high contrast while retaining anodized aluminum’s characteristics.

Anodized Aluminum’s Sheen Surface

Light infiltrates anodized aluminum’s surface through its pores. Therefore, the light reflects from the pores as well as the substrate underneath. The blend of these reflections bestows anodized aluminum with an attractive sheen surface.

How to Engrave Anodized Aluminum

Here’s our step-by-step guide to laser engraving anodized aluminum:

Purchase the Right Anodized Aluminum

Aluminum’s anodized layer comes in different thicknesses and colors. Anodized aluminum’s natural color is metallic gray. However, you’ll get higher contrast if you buy painted anodized aluminum, which comes in many colors.

Hard anodizing (or type III anodizing) produces a thick layer that is highly durable. But that is more expensive and unnecessary for arts and decorative items.

Check What Your Laser Can Do

The table below shows which types of lasers can engrave, etch and cut different types of aluminum:

| Type of Laser | Engrave/Etch Anodized Aluminum | Engrave/Etch Bare Aluminum | Cut Aluminum |

|---|---|---|---|

| Diode Laser | ✅ | ⛔ | ⛔ |

| CO2 Laser | ✅ | ✅ | ⛔ |

| Fiber Laser | ✅ | ✅ | ✅ |

So, you can’t damage aluminum (for example, a Macbook) with a CO2 laser since it can’t cut the aluminum. But you should be more careful about a fiber laser’s settings.

Laser Settings for Engraving Anodized Aluminum

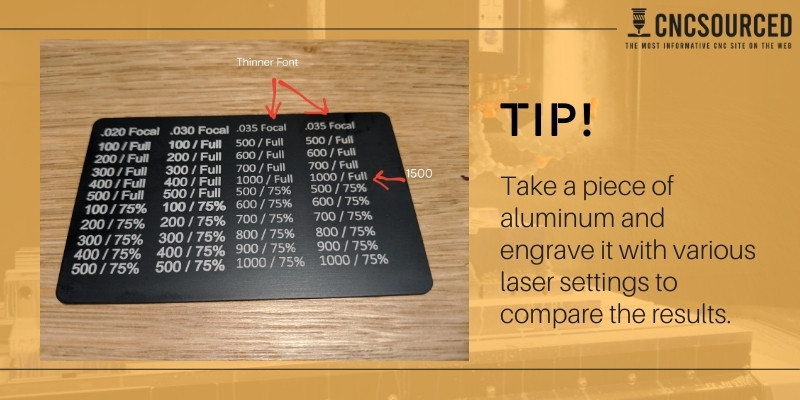

Your laser settings are vital for engraving anodized aluminum. You should experiment here since different settings result in different contrasts.

Generally, the best laser settings for engraving anodized aluminum depend on the laser and the material.

If you have a diode laser or a CO2 laser under 60W, it’s best to use 100% power (or at least above 90%). This is generally true for more powerful CO2 lasers, but you can also use higher speeds with them.

Glowforge’s default setting is a good starting guess for CO2 lasers near 40W: full power (40-45W), full speed (330 mm/s), and 340 dpi. You should increase the speed if your CO2 laser outputs more than 45W. You should also decrease your speed for lower laser beam powers.

With diode lasers, you should use 100% power. The laser speed should be about 100-110 mm/sec for a 10W diode laser. But you can increase the speed for 15W and 20W lasers.

The dpi is usually between 300 and 600. Fiber lasers can engrave aluminum at much higher speeds even with 600 dpi.

My advice is to take a piece of aluminum and engrave it with various laser settings to compare the results. Then you’ll know what settings to use for your intended contrast.

Laser Settings for Etching Anodized Aluminum

Most lasers have default settings for etching anodized aluminum. Laser etching anodized aluminum requires less laser power than engraving, and can be done at higher speeds.

Since your settings depend on the laser (and the material), you should consult your laser manual or forums. But you can also experiment via trial and error by using the following tips:

Tip 1: Use your laser’s highest speed that can engrave or mark the material at full power. For CO2 lasers above 30W, it’s usually the laser’s highest speed. But you may have to use lower speeds for diode lasers.

Tip 2: Lower your laser’s output power until the laser starts to etch instead of engraving.

The difference between etching and engraving is that you can’t scratch off engraving, but any abrasive treatment can wipe off the etched marks.

Does Laser Engraving Destroy Anodized Aluminum?

Laser engraving removes the anodized layer from aluminum. This makes etching anodized aluminum more popular than engraving since it doesn’t affect the anodized layer.

However, engraving anodized aluminum causes no problems under normal conditions.

The anodized layer resists corrosion. However, bare aluminum gradually forms an oxide layer on its own and becomes impervious to further oxidation. So, you won’t have a corrosion problem from engraving anodized aluminum as you would with ferrous metals.

Anodized aluminum is also impressively hard to scratch. Hard anodized aluminum scores a whopping 70 on the Rockwell hardness scale (9 on Moh’s scale, close to diamond!).

Engraving anodized aluminum destroys this hard layer. However, since the engraving is hollow (- not raised), any abrasion that gets through to the engraving only deepens it further!

Engraving anodized aluminum is wrong when it is a machine part that supports bending forces. Therefore, engraving precedes anodizing in manufacturing processes.

But, engraving anodized aluminum doesn’t cause durability problems for art projects, signs, and other popular applications. However, you can etch anodized aluminum if you are worried about its durability.

Some Good Options for Engraving Aluminum

We’ve listed our top pick for each type of laser for anodized aluminum engraving: diode, CO2, and fiber / MOPA.

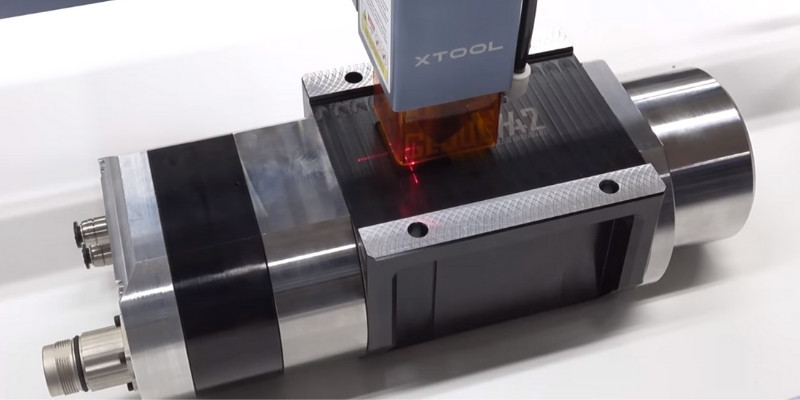

xTool D1 Pro (Diode Laser)

Although xTool D1 Pro can’t engrave bare aluminum, it can engrave anodized aluminum.

The xTool D1 Pro 20W is better at engraving anodized aluminum than the 10W. You can also buy a rotary attachment for it and engrave metal pens, beakers, and more. Some lasers that cost several times the price of xTool D1 don’t have a rotary option – for example Glowforge lasers do not.

We have the xTool D1 Pro 20W in our workshop, and personally we champion it as the best diode laser out. It’s an excellent diode laser for hobbyists or small shops because it gives a tremendous return on investment at its price. We’ve also compared it versus the Ortur LM3 (in our opinion the second best diode laser out) – which is a great option if you want to save a hundred bucks vs the xTool.

Glowforge (CO2 Laser)

- Pricing: Depends on model – check all Glowforge products here

Glowforge is a good option for engraving anodized aluminum (and aluminum in general). Glowforge basic starts at $3995, while Glowforge Plus and Pro cost $4995 and $6995, respectively. Glowforge enjoys a 40W CO2 laser (45W for Glowforge Pro).

Glowforge has already tested different laser settings for engraving gray anodized aluminum. So, Glowforge’s default setting for Macbook engraving is an excellent start for experimenting with anodized aluminum.

Although Glowforge cuts many materials, it can’t cut aluminum (or other metals). Glowforge is well-liked among beginners because it is very beginner-friendly.

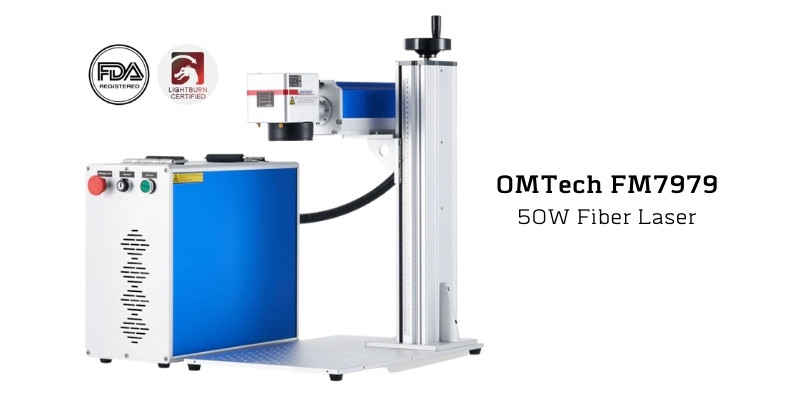

OMTech Lasers (CO2, Fiber, and MOPA Fiber Lasers)

With OMTech, you get many more options than either Glowforge or xTool. OMTech lasers are very diverse and affordable. They have lasers for every application you need at amazingly affordable prices with various working areas. Their FM series are fiber lasers that can engrave aluminum much deeper than other lasers on this list (especially their FM7979 laser).

OMTech DF series lasers also fit right on your desktop. They are powerful CO2 lasers (40W) that are very light and portable. Their engraving area is 8” by 12”, and they can comfortably engrave aluminum.

OMTech also offers larger lasers, such as their MF series. Check out their prices for 60W CO2 lasers with a 20” by 28” cutting area.

You can enjoy auto-focus lasers with OMTech’s AF series. These are surprisingly affordable, large, and powerful CO2 lasers.

You can also get a fiber laser with OMTech’s FM series. These fiber lasers can engrave aluminum much deeper than Glowforge or other CO2 lasers.

Aluminum Engraving Applications

- Your Macbook’s shiny metallic surface is anodized aluminum. You can engrave pictures or your name on your Macbook.

- Metal pens look luxurious with their shiny and lavish surfaces. A laser engraved pen with aluminum shells looks much more personal – and you can also use them to reinforce your brand name.

- You can create high-quality pet tags by engraving anodized aluminum. The pet tag can be in numerous colors if you get painted anodized aluminum sheets for better contrast.

- Engraving aluminum is not just for pets. You can also make shiny name tags with them.

- Making signs out of anodized aluminum is brilliant: it’s easy, and it looks great. You can buy anodized aluminum plates in various colors. Plus, it’s exceedingly durable.

- You can make promotional items from aluminum products like flashlights, pens, and flasks. Your company name looks impressive on these items.

- Cutting and engraving anodized aluminum can bring colorful designs to your jewelry sets.

How Long Does Anodized Aluminum Last?

Type II anodized aluminum lasts 10-20 years. However, its life depends on the Anodized layer’s thickness. Type III anodized aluminum should last over 20 years.

Can You Laser Etch Anodized Aluminum?

Yes, you can also laser etch anodized aluminum. Laser etching anodized aluminum is more popular than laser engraving it, as etching anodized aluminum is faster and less intrusive than engraving. Etching maintains anodized aluminum’s good surface characteristics.

Can xTool D1 Engrave Anodized Aluminum?

Yes. The xTool D1 Pro can engrave anodized aluminnum, though it cannot engrave bare aluminum. The engraving will be very shallow (about 0.00001mm). The engraved area is gray, so the white and gray contrasts and shines against dark-colored anodized aluminum.

Can Glowforge Engrave Anodized Aluminum?

Glowforge can engrave both bare aluminum and anodized aluminum. Glowforge has pre-made settings for etching Macbooks, which work on anodized aluminum. Glowforge’s engraving contrast works best if the anodized aluminum’s color contrasts with gray.

How Strong of a Laser Do You Need to Engrave Aluminum?

Lasers above 30W can engrave bare aluminum as well as anodized aluminum. However, weaker 15W diode lasers can also engrave anodized aluminum – but not bare aluminum.

Can You Laser Engrave Aluminum With a Diode Laser?

Diode lasers can’t engrave bare aluminum. However, diode lasers can engrave aluminum if it has an oxide layer. Therefore, diode lasers can engrave anodized aluminum.

What Kind of Laser Do You Need to Laser Engrave Aluminum?

You can engrave bare aluminum with a CO2 or a fiber laser. However, you can engrave anodized aluminum with a diode, CO2, or a fiber laser. Fiber lasers can also cut aluminum, while other lasers can’t.

Can a 10W Laser Cut Aluminum?

10W lasers can’t cut aluminum (though they can engrave anodized aluminum). You need much stronger fiber lasers to cut aluminum.

For more answers on laser cutting and engraving metals and other mateirals, we can an article on laser cutter materials.

Final Thoughts

Anodized aluminum is ideal for laser engraving and laser etching. Most lasers can engrave and etch anodized aluminum, while only CO2 or fiber lasers can engrave bare aluminum. Glowforge, xTool D1, and most other lasers can engrave anodized aluminum with ease.

Anodized aluminum is ideal for engraving since it has a tough surface that resists corrosion and scratch, has an attractive sheen, and comes in various colors.

Engraving anodized aluminum has many applications. Using the right laser settings, you can engrave Macbooks, iPads, metal pens, and name tags.

If you enjoyed this article, you’d enjoy our laser engraving guides:

- Color Laser Engraving Full Guide

- How to laser etch metals with a laser engraver

- Buyer’s Guide: Laser Cutters & Engravers For Every Budget!

- The best metal laser engravers

- Best CO2 lasers

- Best fiber lasers

- Most Affordable Pro Glass Laser Engraving Machines