Key Takeaways

- Laser cutter temperature: The temperature generated by a laser cutter depends on the material being cut, the power of the laser, and the air pressure. The temperature can range from 150℃ to 5550℃ (302℉ to 10022℉) for different materials and lasers.

- Laser beam heat: The laser beam itself does not have heat, but it carries heat energy to the material. The material reaches its boiling point, melting point, or decomposition temperature when cut by the laser.

- Laser cutting speed: The speed of the laser cutter affects the amount of heat delivered to each point on the material. A faster speed means less dwell time and less energy per point4. A slower speed means more dwell time and more energy per point.

- Laser cutting fire: Laser cutting can start a fire if the material is flammable, such as wood or leather. To avoid fire, use the right laser parameters, air assist and exhaust, and a fire extinguisher. Always attend to the laser when it is running.

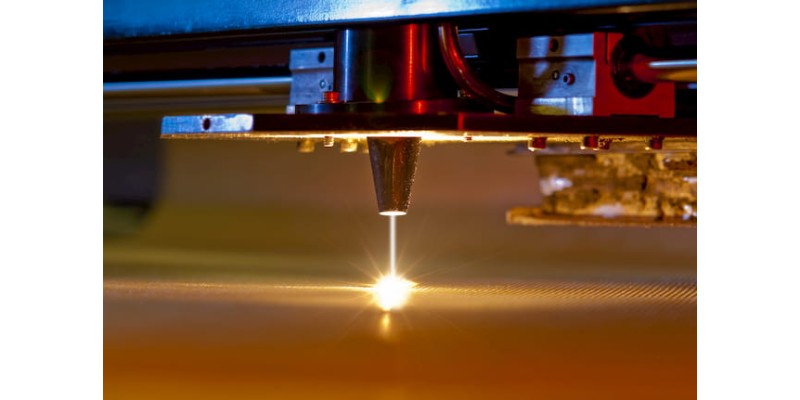

In movies and TV shows, we are often captivated by the mesmerizing sight of laser beams effortlessly slicing through various objects. You might have been wondering about the true power and intense heat generated by real-life laser cutters.

Standard 40W-100W CO2 lasers reach maximum temperatures of between 150℃ and 500℃ (302 and 932°F) depending on the material. Industrial CO2 lasers and fiber lasers can reach up to 5550℃ (10022°F) on tungsten, and typically generate temperatures between 2470℃ to 3290℃ (4478℉ to 5954℉) on common metals.

Standard diode lasers with 5-20W power reach 150℃ and 500℃ (302 and 932°F), and max out at 250℃ (482°F) when failing to decomose plastics.

Scientific x-ray lasers have also reached 2 million celsius (3.6 million Fahrenheit), though these are not related to laser cutting.

What is the maximum temperature a laser can reach?

| Laser Type | Highest temperatures reached |

|---|---|

| Diode lasers | 150℃ and 500℃ (302℉ and 932℉) |

| Low-powered CO2 lasers (40-100W) | 150℃ and 500℃ (302℉ and 932℉) |

| Industrial CO2 lasers | 5550℃ (10022℉) in tungsten |

| Fiber lasers | 5550℃ (10022℉) in tungsten |

| X-ray scientific lasers | ≅2M℃ (3.6M℉) |

Understanding the physics laws of heat is crucial in determining the maximum temperature that a laser can reach. By applying our knowledge of physics, we can accurately calculate the temperature generated by a laser cutter.

In this article, I will explain the factors that affect laser cutter temperature, including the properties of the material being cut, the characteristics of the laser, and the surrounding air pressure.

The Science Behind Laser Cutter Temperatures

How hot is the laser cutter’s beam?

Well, technically, because heat only relates to matter, and because laser beams have no matter as they are light waves, they have no internal heat (internal thermal energy).

So while laser beams do not have heat themselves, they carry heat energy to materials and make the materials hot.

So, how hot does the material get when shot with a laser beam?

This temperature depends on the material. The laser cutter will reach the temperature of the material’s boiling point or melting point as I’ll explain. For materials that degenerate before boiling, the limit is the decomposition and burning temperature.

So, more powerful lasers will not generate higher temperatures than cheap ones if this is beyond the material’s boiling point. A more powerful laser cutter can generate more heat, but that heat will not increase the temperature beyond the material’s boiling point.

So, how can you measure the temperature a laser cutter can generate?

You can calculate the temperatures a laser cutter can generate by looking at the materials it can cut or engrave or etch.

Then, look up the boiling point for that material to find the temperature when laser cutting or engraving, or the material’s melting point for etching. Also, not all materials have a boiling point. Some materials like wood and leather decompose before they can evaporate.

The laser cutter:

- Momentarily generates the material’s boiling point when engraving.

- Consistently generates the material’s boiling point when cutting.

- Generates the material’s melting point when etching.

- Generates the material’s decomposition temperature in plastics, wood, and leather.

Equipped with this knowledge, let’s find various laser cutter temperatures. Also, keep in mind that the temperatures we’ll calculate will be slightly lower at higher altitudes. So, if your city is 1500m above sea level, you’ll reach slightly lower temperatures with a laser cutter.

How hot do CO2 lasers cut?

Low-powered CO2 lasers with 40-100W power can generate temperatures between 150℃ and 500℃ (302℉ and 932℉) if cutting materials like acrylic, wood, leather, or plastic.

| Material | What Laser Cutter Achieves | Laser Cutter Temperature ℃ | Laser Cutter Temperature ℉ |

|---|---|---|---|

| Wood | Decompose and burn | 260℃ | 500℉ |

| Leather | Decompose and burn | 150℃ | 302℉ |

| Plastics and acrylic | Decompose and burn | 250℃ to 500℃ | 482℉ to 932℉ |

| Glass | Mark by breaking oxygen trapped zones | Low temperatures | – |

Note: Wood decomposes before vaporizing. According to UW Madison, this happens at 500℉.

High-power industrial CO2 lasers with, for example, 4KW power, can generate more heat and cut more materials.

These temperatures are around the same as fiber lasers: 5550℃ (10022℉) in tungsten, and typically between 2470℃ to 3290℃ (4478℉ to 5954℉) on common metals.

| Material | Laser Cutter Temperature ℃ | Laser Cutter Temperature ℉ |

|---|---|---|

| Glass | 1500℃ | 2732℉ |

| Metals (See fiber lasers below) | Up to 5550℃ | 10022℉ |

How hot do diode lasers get?

Consumer diode lasers used by hobbyists generally aren’t all that powerful, as their power outputs usually range from 5 to 20W. They can’t decompose and vaporize some plastics, such as clear acrylic.

Diode lasers generate temperatures between 150℃ and 500℃ (302℉ and 932℉), but if they just melt plastic before they can decompose it, their temperature maxes out at 250℃ (482℉).

| Material | What Laser Cutter Achieves | Laser Cutter Temperature ℃ | Laser Cutter Temperature ℉ |

|---|---|---|---|

| Wood | Decompose and burn | 260℃ | 500℉ |

| Leather | Decompose and burn | 150℃ | 302℉ |

| Plastics and colored acrylic | Some melt and some decompose and burn | 250℃ to 500℃ | 482℉ to 932℉ |

How hot do fiber lasers get?

Fiber lasers can generate temperatures of 5550℃ (10022℉) in tungsten but generate lower temperatures in other metals, usually above Aluminum’s 2470℃ (4478℉).

| Material | Boiling Point ℃ | Boiling Point ℉ |

|---|---|---|

| Cadmium | 767℃ | 1413℉ |

| Aluminum | 2470℃ | 4478℉ |

| Chromium | 2670℃ | 4838℉ |

| Cobalt | 2925℃ | 5297℉ |

| Gold | 2800℃ | 5072℉ |

| Iron | 2870℃ | 5198℉ |

| Titanium | 3290℃ | 5954℉ |

| Molybdenum | 4651℃ | 8403℉ |

| Tungsten | 5550℃ | 10022℉ |

How hot do x-ray lasers get?

X-ray lasers only exist in facilities for scientific research. The temperatures generated by these lasers are not subject to the boiling point rule I discussed earlier, because the boiling point of materials is measured on Earth at the air pressure of 1 bar.

These X-ray lasers heat the core of a material, not its surface; the material vapor it produces in the core is momentarily under immense pressure. Therefore, the physics law of ideal gas dictates that the material reaches boiling point at a much higher temperature.

The highest temperature was recorded in 2012, when Oxford researchers used an X-ray at the SLAC on a piece of aluminum. It reached 2 million degrees Celsius (3.6 million degrees Fahrenheit). SLAC stated that this lasted less than one trillionth of a second.

What can laser cutters burn through?

Laser cutters can burn through many different materials, but the types of material that your laser cutter will be able to burn through will depend on two factors:

- The type of laser you are using.

- The laser’s output power.

Generally, a high-power laser cutter should be able to burn through materials like:

- Glass

- Wood

- Steel

- Plastic

- Cardboard

- Paper

- Foam

- Brick

- Bone

- Aluminum

- Rubber

- Fabric

- Precious metals

- Nickel

- Fiberglass

- Copper

- Carbon fiber

- Carbon steel

More a more in-depth guide into which types of lasers can cut and engrave which materials, I recommend reading my laser cutter materials guide.

How does cutting speed affect the heat from a laser cutter?

The amount of heat a laser beam packs is only affected by its output power. So, a laser with 40W output power will generate 40J (Joules) of heat every second when it’s running at 100% power output.

However, the speed affects the amount of heat the beam delivers to each point.

For example, at the speed of 1mm/s, the 40W laser beam delivers 40J to a 1mm line. Now at 10mm/s, the same 40W laser delivers 40J to a 10mm line.

In other words, increasing the speed lowers the beam’s dwell time and results in each point receiving less energy (per time unit).

How can I measure the temperature of a material when laser cutting?

To measure the temperature of the affected zone, or the areas around it, you can point a thermometer gun at the material.

But, all you need to measure the maximum temperature of the material being lasered is to know the materials’ boiling, melting points, and decompositions temperatures. When the laser cut or engraves the material, it reaches that material’s melting point in temperature.

Can a laser cutter start a fire?

Yes, it is definitely possible for a laser cutter to start a fire, especially if you’re cutting through non-metallic materials like wood or leather. If you’re cutting organic materials that are flammable, you should take precautions when laser cutting them.

To avoid fire, use the right laser parameters of power and speed, use air assist and exhaust, and always attend to the laser when it’s running. Also, keep a fire extinguisher in the room with the laser.

For a complete list of safety measures you should take when laser cutting, I recommend reading my guide on laser cutter safety and hazards.

FAQs

How hot is a Glowforge laser cutter?

A Glowforge laser will generate temperatures between 302°F and 932°F, depending on the material being cut. A Glowforge laser can’t cut through metal, but the highest temperatures it generates are when cutting acrylic and other plastics.

Do laser cutters generate more heat than plasma cutters?

No, plasma cutters generally have a wider kerf of cut, so they melt and vaporize more material and deliver more heat to material for cutting than laser cutters. However, laser cutters may generate more heat in your local surrounding, as lots of heat is generated that is not absorbed by the material. In this case, the answer of which generates more heat depends only on their power output: the higher the power output the more heat the machine generates, overall.