The best glass laser cutters and engravers work very differently to wood or acrylic – you’ll need to paint or spray your glass with a diode laser to get an engraving effect, whereas CO2 lasers are much easier to use.

For a CO2 glass laser cutter, you can technically go for a cheap K40, but I don’t recommend it. It’s too small to get tumblers or glass bottles in, and I recommend spending more to get a laser like the xTool P2, which in my opinion is the best desktop CO2 laser right now.

|

CNCSourced Rating: |

CNCSourced Rating: |

|

4.8

|

4.7

|

|

$4,299

|

$629.99

|

|

Speed:

300 mm/s to engrave glass

|

Speed:

30 mm/s to engrave glass

|

|

Laser Power:

55W

|

Laser Power:

10W (20W and 40W also available)

|

|

Laser type:

CO2

|

Laser type:

Diode

|

That being said, if you want a low-cost diode laser for glass engraving, I recommend the xTool D1 Pro. It’s my favorite laser in my workshop, and I think it’s the best diode laser out right now – but I still recommend a CO2 laser for engraving and etching glass if you have the budget.

| Laser Name | Work Area | Power | Glass Engraving Speed | Price |

|---|---|---|---|---|

| xTool D1 Pro | 432 × 406 mm | 10W (20W and 40W available) | 30mm/s at 10W, up to 100mm/s at 40W | $629 |

| xTool P2 | 600 x 308 mm | 55W | 300mm/s | $4,299 |

| Neje Master 3 | From 170mm×170mm to 460mm×810mm | 5.5W to 11W | 15-50mm/s | Varies |

| OMTech 80W | 500 x 700 mm | 80W | Around 250mm/s | Around $3,000 |

In this buyer’s guide, I’ll explain exactly what laser engraving glass is and how it works (for both diode and CO2 lasers), I’ll run through the best laser cutters for glassware, and explain the key factors to consider when buying (hint: it’s NOT power or speed).

Best Glass Laser Engraving Machines

1. xTool P2 – Best CO2 Laser For Glass Etching

- Price: Check at xTool here

- Working area: 600 x 308 mm

- Laser type: CO2

- Power: 55W

Pros

Comfortably engraves glass at 300mm/s.

Faster engraving than other CO2 lasers like Glowforge Pro (and it’s also cheaper)

Low-cost rotary glass engraving with RA2 rotary pro add-on.

Cons

Need the riser base accessory for rotary engraving taller glasses.

| xTool P2 | Material Settings | ||

|---|---|---|---|

| Glass Material | Process type | Power(%) / Speed(mm/s) / Lines per cm / Passes | Bitmap mode |

| Plain white glass sheet | Scoring | 10 / 160 / – / 1 | – |

| Plain white glass | Vector engrave | 10 / 300 / 100 / 1 | – |

| Plain white glass | Bitmap engrave | 10 / 300 / 100 / 1 | Jarvis |

| Shot Glass Etching | Bitmap Laser Engrave | 30 / 250 / 140 / 1 | Jarvis |

I personally think the xTool P2 is the best desktop CO2 laser right now based on my hands-on testing, including for glass engraving.

No other laser gets you 55W power, such large working area, advanced features, and precision for the price. I also found the low-cost $279 RA2 rotary add-on was ideal for engraving on glass vases, bowls, cups, and more.

Though, you may not even need the rotary for some curved surfaces, such as glass bowls. The xTool P2 uses dual 16MP cameras which can detect different heights and depths across the glass workpiece, and create a 3D mesh (similar to how a 3D scanner works).

Then, the laser adapts your design across this curved surface so that it comes out perfectly, without distorting. I haven’t tried this on a glass bowl yet, but I’ve tried this on wooden bowls and spoons, for example this spoon below:

Here’s my video guide on how to engrave on these curved surfaces with the xTool P2:

The power and accuracy means you can get that crystal-style glass engraving on glass, though I recommend buying the riser base accessory if you want to do rotary engraving, as this will give you more height – up to 8.5”. Without this, you’ll be limited in the size of glasses you can etch into.

If you’re engraving a bunch of glass coasters at the same time, the P2 also has built-in batch processing features within the XCS software. This means that if you align the laser on one glass workpiece, and click the “Smart Fill” button, it’ll automatically align across all other workpieces the cameras detect, in the exact same way.

For small business owners looking to create a lot of branded products quickly, this is a huge bonus. You can see how it works below:

Even with the riser base, RA2 rotary pro, and the automatic conveyor feeder, the xTool P2 is still cheaper than the Glowforge Pro. (though the feeder isn’t really important for glass engraving; it’s more for really long wooden sheets).

And overall, I highly recommend it if you’re looking for a CO2 laser for your small business. Not only does it work well with glass, but it can cut 20mm acrylic and wood in a single pass, and etches well on metal.

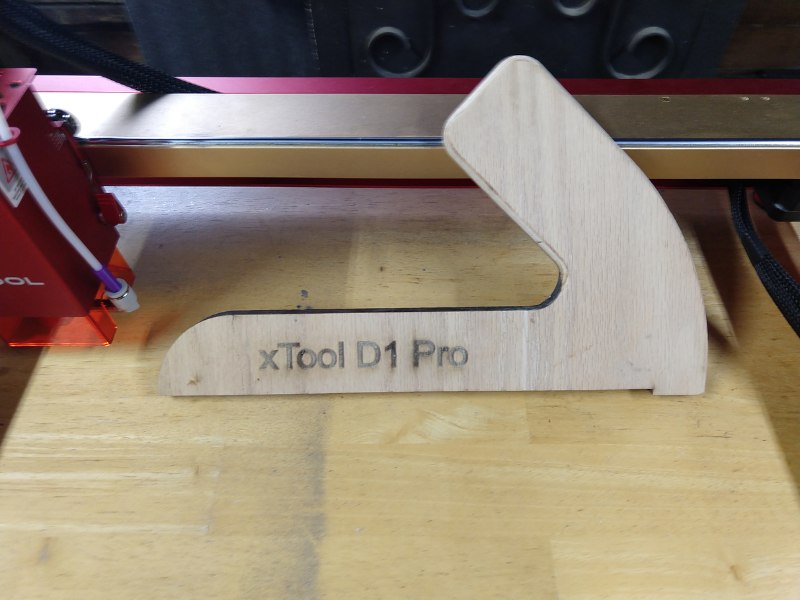

2. xTool D1 Pro: Best Diode Laser For Glass

- Price: $699 — Available at xTool here

- Work Area: 432 × 406 mm

- Laser Power: 5W, 10W, 20W, 40W options

- Assembly Time: 30 minutes

- Laser Type: Diode

- Rotary Attachment? Yes Available at xTool here

Pros

The best diode laser in the price range (in our opinion)

Rotary and risers: for engraving glass cups and bottles

Extension kit option: increases work area to 936 x 432 mm

Compatible with Lightburn

Cons

Diode laser: so you’ll have to paint the glass before engraving, and you’ll get worst grayscale glass engraving results

| xTool D1 Pro | Material Settings | |

|---|---|---|

| Laser Type | Type of Glass | Power(%) / Speed(mm/s) / Lines per cm / Pass / Mode |

| All | General | 50 / 100 / NA / 1 / Grayscale |

| 40W | Personalized laser etched glass | 35 / 100 / NA / 1 / |

| 20W | Wine Glass | 100 / 25 / NA / 1 / NA |

| 10W | Mirror & Clear Glass | 100 / 30 / 100 / 1 / Bi-directional |

| 10W | Drinking Glass | 100 / 12 / NA / NA / NA |

| 10W | Antique mirror effect with laser | 5 / 80 / NA / 1 |

xTool D1 is an excellent diode laser ideal for low-cost glass laser engraving. It’s very well-built, with a sturdy metal chassis making for controlled movement and great precision, and with protected belts (other lasers like my Ortur Laser Master 3 don’t have protected belts).

You can get it with a 5W, 10W, 20W, and a brand-new 40W laser head – so take your pick based on how much power you need. xTool also offer two laser head choices: infrared and blue. I personally own and have tested the 20W xTool D1 Pro, and I think it’s the best diode laser around right now.

However, if you’re buying, consider that being a diode laser, xTool D1 is not great for a glass engraving business since you can’t directly laser engrave glass – you’ll need to paint or spray it first.

My xTool P2 is better suited to glass engraving, as it’s a CO2 laser. But, you can still laser engrave glass with the xTool D1 Pro, you just need to be clever with painting and preparing the glass.

Another plus is its cheap risers and rotary add-on. While not as cheap as Ortur’s YRR rotary (which is a DIY kit, taking a while to build and generally more annoying), xTool’s RA2 rotary chuck is sturdier and better built, and lets you hold glass pitchers, wine glasses, cups, and bottles in place to engrave them. If you’re unsure as to which power version to go for, I’ve compared them all in our xTool D1 Pro 5W vs 10W vs 20W article.

And if you need even more power, go for the 20W version (we did!)

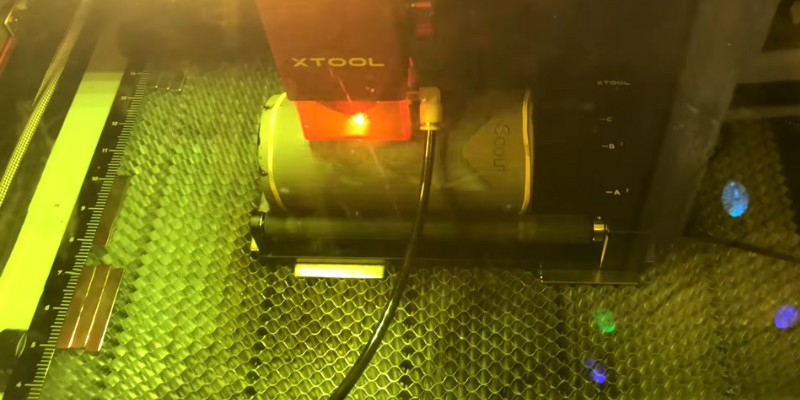

3. NEJE Master 3 – Budget Pick

- Price: Check latest price on Amazon here

- Power: 5.5W

- Working Area: from 170mm×170mm to 460mm×810mm

- Assembly Time: 1 hour

- Laser Type: Diode

- Rotary Attachment? Yes

Pros

Various work area options: including large-scape option

Very affordable

Cons

Diode laser, so have to paint glass – not great for grayscale engraving

Low power (compared to xTool D1 Pro)

| NEJE 3 | Material Settings | |

|---|---|---|

| Neje Model | Glass | Power(%) / Speed(mm/s) / Pass |

| Neje 3 Plus | Sheet | 80 / 15 / 2 |

| NEJE 3 Max V2 & A40630 | Bottle | 70 / 50 / 1, Air Assist = off |

| NEJE 3 MAX &E40 | Glass Carved Santa Claus | 100 / 5 / 1 |

| NEJE 3 PRO with the A40640 | Transparent Glass | 90 / 16 / NA, Jarvis = 0.1 |

NEJE is a name quickly growing in the laser engraving space for its insane affordability, and it’s that exact reason why it’s on our list today.

By all accounts, the NEJE 3 Plus is a fantastic machine. You can order it in various sizes and working areas with 110mm×120mm, 170mm×170mm, and 460mm×810mm options.

It has a very narrow beam, which can engrave precise designs on wood, leather, rubber, and loads of other soft materials… just not glass, at least in the traditional sense.

The NEJE 3 uses a diode laser, and for those new to the game, diode lasers can’t cut or process glass as the laser beam just goes through it, like pouring water through a strainer. Therefore, in order to use it for glass engraving, you’ll have to use film-coated glass or paint the glass black before engraving, then use paint thinner to clean it afterward.

Now, this is a turn-off for experienced hobbyists or professionals with strict deadlines, products, and operations they’re trying to achieve, however, if you’re new to laser engraving, then this is the perfect machine to beat the learning curve.

Once you’re more experienced and have more money to invest, I recommend buying a more expensive glass laser cutter and engraver, but this is the best solution for new users looking to explore the space. If you’re on a budget, this is one of the best laser engravers under $500.

You can see this machine engraving glass in this video:

As you can see, laser settings of about 80% power and about 10mm/sec yield good results.

Hot tip: The darker the paint the better the result when glass laser engraving with a diode laser.

Acrylic engraving is now more affordable than ever thanks to NEJE and their line of cost-effective laser engravers.

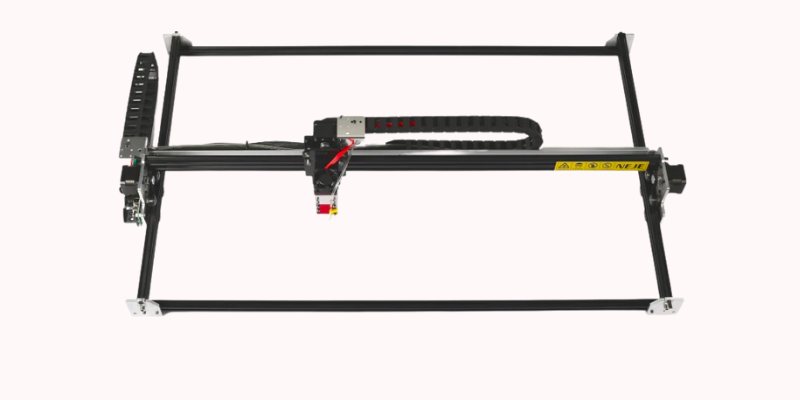

4. OMTech 80W – Large Size Laser Cutter For Glassware

- Price: Check price on Amazon here

- Engraving area: 500mm x 700mm

- Power output: 80W

- Assembly Time: Pre-assembled

- Laser Type: CO2

- Rotary Attachment? Yes

Pros

High power: powerful 80W laser for fast glassware laser engraving

Large work area: 500 x 700 mm is larger than most competitors

Good value: it’s far from cheap, but for the specs, it’s very affordable

4-way pass through doors to engrave unlimited lengths of glass

Over 9” of lift table with optional auto lift – roomy enough for all glassware

Supports Lightburn

Autofocus

Cons

Not a desktop laser: it weighs 287 pounds. Far from portable, and made for small businesses and shops in workshops

| OMTech 80W | Material Settings |

|---|---|

| Model | Power(%) / Speed(mm/s) |

| USB570w & USB570z | 18 / 225 |

The 80 W is from OMTech’s mid-range series, unlike the 40W K40 laser which is from their desktop range. This machine oozes power and is for those working on large glass projects – and a lot of them.

This is highlighted by its 80W laser tube that cuts up to a whopping 9mm deep, and four-way pass-through system, which has openings on the sides, front, and rear of the machine. This lets you to work on projects longer and wider than the machine itself. The 80W power also means you can engrave even tougher materials than glass, including brick, marble, and granite.

This is by far one of the strongest at-home laser engravers you can buy and is best for growing businesses – literally. With its pass-through system, you can grow the size of the projects you want to take on and expand the range of projects you can hit, conquering your previously untouched markets.

It’s compatible with CorelDraw and LightBurn, two of the most popular design software. However, this is an industrial-level machine, so you are required to complete some safety requirements before using it. Overall, it’s one of the best laser engravers for glass and metal.

The focus of this machine's design is on size and power, so if you want to work on large-scale acrylic projects, it will easily fulfill demand.

How To Pick a Laser Engraver for Glassware

Laser Type

This depends on your needs: if you’re just doing the occasional fun glass project at home, etching glass with a diode laser is fine. If you’re buying a laser for a glass engraving business, then only go for a CO2 laser. CO2 lasers can engrave glass, and high-power CO2 lasers can even cut glass.

However, if you already have a diode laser, you can experiment with glass engraving by first, putting black paint on the glass and washing it off afterward – and then decide if you want to buy a CO2 laser from there.

Z-Axis and Rotary

If you’re only engraving glass sheets, then you don’t need a rotary. But, if you want to engrave wine glasses, bottles, pitchers, and cups, then you’ll need one.

But a rotary is not enough. You’ll also need a laser with enough room under its Z-axis to place cups and bottles. For example, the OMTech 80W and Ten High CO2 lasers can accommodate glassware, while Flux Beamo and OMTech 40W are still too low to engrave larger bottles and pitchers, despite having rotary add-ons. And Glowforge lasers notoriously have no rotary attachment as there’s not enough z-height.

Finally, if the Z-axis has motorized movement (auto lift), you don’t have to adjust it manually.

| Laser Machine | Rotary Attachment |

|---|---|

| xTool D1 Pro | Yes |

| NEJE Master 3 | Yes |

| OMTech 80 W | Yes |

| xTool P2 | Yes |

Work Area

The work area limits the size of glass sheets you can engrave. You only need a work area as big as your projects.

Some lasers also have pass-through doors that allow you to insert long glass sheets for engraving, such as the OMTech 80W and Glowforge Pro.

| Laser Machine | Work Area |

|---|---|

| xTool D1 Pro | 432 x 406 mm |

| NEJE Master 3 | From 170mm×170mm to 460mm×810mm |

| OMTech 80 W | 500mm x 700mm |

| xTool P2 | 600 x 308 mm |

Cost

Your projects affect the laser you choose for the work area, z-height, whether you need a rotary, and your laser type. But once you know your requirements, price is the main factor in picking the best laser cutter for glass.

Glass laser engraving machine prices start at around $500 for the cheapest CO2 lasers. However, a larger CO2 laser with a roomier work area for larger and taller glass projects starts at around $3000. From there, you can get more expensive machines with more advanced features.

| Laser Machine | Price |

|---|---|

| xTool D1 Pro | $699 |

| NEJE Master 3 | $499 |

| OMTech 80 W | $3,699 |

| xTool P2 | $4,399 |

Speed and Power

This factor is not as important for glass engraving as for other types of material engraving. For example, we’d put power on top of the list for cutting wood, but for glass engraving, it’s a lesser factor.

For diode lasers, higher power is just better. But for glass engraving with a CO2 laser, higher power only affects your production rate if it can engrave at higher speeds – otherwise, you won’t use all of the laser power.

| Laser Machine | Max Engraving Speed | Power Options |

|---|---|---|

| xTool D1 Pro | 400 mm/s | 5W, 10W, 20W, 40W |

| NEJE Master 3 | Unknown | 5.5W |

| OMTech 80 W | 500 mm/s | 80W |

| xTool P2 | 600 mm/s | 55W |

Versatility

You’ll most certainly use your laser to cut or engrave other materials as well. So, a laser with more capabilities and material compatibility will also help you there.

So, while if you’re only using it for glassware laser projects, you can prioritize just these factors, but I also implore you to consider any other projects you’re likely to make, especially if you’re running a small shop, or an Etsy store.

With glass you can make awesome projects like trophies, custom signage, promotional materials for clients, engrave whiskey and other bottles, optics, pictures, mirrows, and even christmas decorations.

But, if you want to work with acrylic, wood, or metals, pick a laser that is better suited to these other materials too.

Buy a glass laser cutter that also works on signs if you plan to make these, or that can effectively laser engrave yeti cups made of stainless steel or anodized aluminum, as well as glass tumblers.

What type of glass are you working with?

There are different types of glass, which each suit differenet types of projects best. Here’s a quick guide:

- Soda-Lime Glass: The most common and inexpensive type of glass, used for windows, bottles, and glassware. It provides a smooth, clear surface for laser engraving.

- Borosilicate Glass: Used for laboratory equipment, cookware, and other high heat applications. Its durability makes it suitable for deep laser engraving.

- Lead Crystal Glass: This type of glass contains typically 24% or more lead oxide, which gives it a sparkling appearance. It is commonly used for high-end glassware, decorative items, awards and trophies, and optics.

- Tempered Glass: Thermal tempered glass is more resistant to breakage and impact, and is often used for architectural applications, and its strength allows for detailed laser engraving.

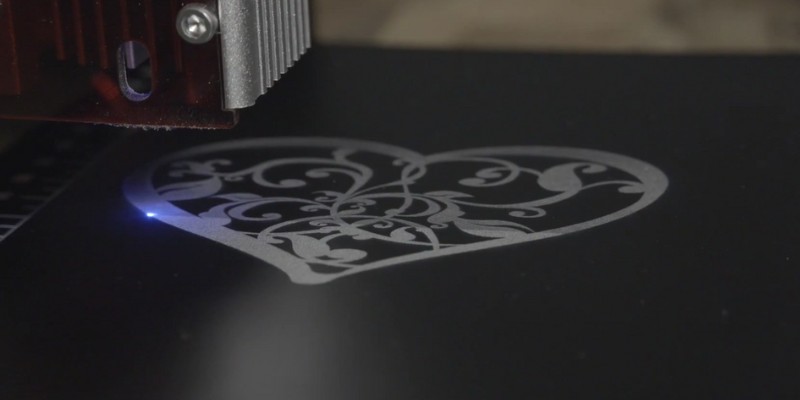

How to Laser Engrave Glass

Laser engraving glass is different from engraving other materials like wood. When you engrave wood, you get the engraving effect because the laser removes a small portion of the material, but when engraving glass, it’s because the laser causes small cracks in the glass.

So, the glass surface does not evaporate like other materials do, even though some of the trapped air escapes from the glass surface, cracking it.

Lasers are also different to traditional glass engraving techniques like acid etching or sandblasting.

CO2 lasers are best for engraving glass since their beam interacts well with glass. I recommend using a CO2 laser if you’re planning on serious glass projects for your business. However, you can also engrave glass with a diode laser by painting the glass black, but it’s a more complex and slower process.

Engraving Glass With a CO2 Laser

To engrave glass with a CO2 laser, do the following:

- Use wet paper towels or dishwashing liquid to keep the glass from getting too hot.

- Use a lower dpi. Depending on the laser and settings, the dpi can be between 300 and 600. A higher dpi results in the engraving cracks invading each other and decreasing the quality, and even increasing the chances of breaking the glass.

- Use a grayscale matrix between 70% to 80%. If you go any higher, you run the risk of overheating some areas.

Engraving Glass With a Diode Laser

To engrave glass with a diode laser, do the following:

- Clean the glass.

- Paint the glass.

- Set up your project (one-color designs are better than grayscale).

- Use the appropriate laser settings.

- After engraving, wash the glass with paint solvent to remove the paint.

Tips and Tricks For The Best Results

1. Avoid making more than one pass

Avoid going over your design for a second pass, even if the first pass has not come out as well as you expected. Second passes can cause cracking or shattering from the laser’s heat, and can worsen the finish and cause flaking. For more information on this, you can read this article by FocusedLaserSystems.

2. Mask the area

Masking the area by placing wet paper towels or newspaper over the area can help with the heat dissipation when lasering, minimizing the negative impact on the glass surface area such as via mini fractures.

What’s Changed?

We’re constantly updating our articles based on our latest hands-on reviews.

Feb 2024 Updates:

- Removed the OMTech K40, Ten-High CO2, and Glowforge. We now recommend only the lasers we feel are best for glass.

March 2024 Updates:

- Updated with more data from tests and including third-party data on the best settings for each laser to etch glass.

FAQs

Is it hard to laser engrave glass?

It’s easy to laser engrave glass with a CO2 laser, but more difficult to do with a diode laser since you need to paint the glass and wash it off after engraving. It’s also more difficult to engrave rounded objects like cups and bottles, as you’ll need to set up a rotary to do this.

You may also like:

- The best acrylic laser cutters

- The best wood laser cutters and engravers

- The best laser engravers for metal

- Small jewelry engraving machine

- Best Laser Engraver For Leather

- 7 top Glowforge alternatives

- Laser marking vs engraving vs etching vs ablation

- Color laser engraving guide