In this article, we’ll look at the top CNC router accessories and how they can make your life much easier when cutting, scoring, and engraving.

Some on our list are essential must-haves, others are just nice to have. But at the end of the day, convenience is king.

So, in this article, I’ve selected the best CNC accessories I believe everyone needs in their CNC kit, as well as some personal thoughts and tips.

Top CNC Router Accessories

1. Tool Length Sensor/ Z-Probe

It’s difficult to define the Z-zero plane before starting the cut. A Z-probe or a tool length sensor automatically measures the position of the tip of the tool and automatically uses the G43 code to compensate the tool length.

The sensor automatically measures the length of the tool, correcting the coordinates so that your tool is at the right height.

This helps you get precise measurements when changing tools and relieves you from measuring the Z planes every time you change a tool. It also helps to show whether the parameters of the tool are damaged.

2. Spindle/Router LED Light

A Spindle/Router LED light is attached to the router or spindle to shine a light over what you’re working on.

You would usually attach the LED lights around the spindles to show precisely where your CNC routers work.

Most CNC Spindle/Router LED lights are easy to wire straight to your router.

You can select the color of light that best suits your needs—white light for brightness and yellow light for general lighting.

An LED light will make all the difference if you work at night.

3. CNC Router Bits

CNC router bits are some of the most essential tools you’ll work with when using your CNC router. The bits are the pieces that do the actual carving.

Different CNC bits determine the types of carvings you can do. The speed and shape affect the materials the CNC machine bits can carve into.

Here are the main types of CNC router bits:

- End mills: These are generally used for flexible, thinner materials with flat bottoms.

- Bottom clearing bits (skimming bits): Usually used for surface-level clearance.

- Ball nose bits: Mainly used for 3D surface finishings.

- V-bit: These bits are shaped like a V and are a good option for signs, lettering, engraving, and intricate designs.

- Ball nose end mills: Similar to the end mills above, however, they feature a ball at the end. This helps with cutting around edges to produce a rounded contour.

- Surfacing bit: These are like bigger end mills. They are suitable for removing large amounts of materials. They’re also great for smoothing out surfaces like wood.

- Carving bits: These are usually for 3D projects. They can give you a lot of detail that you want for 3D carvings. They can be more expensive, so they are not something to jump into when you’re just getting started.

- T-slot cutters: As the name suggests, these are used to create T-slots in boards and beams.

- Engraving bit: This is specifically for etching designs into metal, glass, acrylic, or wood. It can give you a lot of detail, but it takes practice to get things precise.

- Diamond-coated bits: These are specifically for engraving into stone or granite.

I recommend starting with a few CNC bits from reputable suppliers that you know you will use and growing your tool kit from there. If you know you’re using one or two particular CNC bits regularly, buying two or three is best.

Your CNC bits will wear down over time, and you don’t want to be stuck waiting for a new bit to arrive. Some are pretty tricky to get your hands on, and waiting a week is frustrating when you’re ready to go.

For a more in-depth guide to every type of CNC router bit, endmill, and turning, drilling and grinding tools, we have a guide to every type of CNC machining tool.

4. Tool Holder

A CNC tool holder is designed to hold your cutting tools in place. Accuracy is one of the most essential things with CNC router tools. Unfortunately, if any pieces go wrong, it can offset your position. Even a slight inaccuracy can ruin an entire project.

That’s where CNC tool holders come in. It holds tools in their precise place, preventing them from going off the mark.

Depending on the type you want, you can select CNC tool holders with a firm grip that holds the tool in place. Alternatively, there are tool holders that float to prevent your tools from getting damaged over time.

A tool holder is easy to set up and can keep your tools in working order much longer.

5. Automatic Tool Changer Forks

Automatic Tool Changer Forks are devices CNC machines use to change a cutting tool automatically.

It grabs and releases the cutting tools stored within the spindle or holder.

You should make sure that your spindle is compatible with ATC. Only spindles that have internal chuck opening and closing mechanisms are compatible with ATC. Consider that these spindles are not cheap.

When initiated, the CNC router commands the tool changer to rotate the arm to the needed tool holders. Once there, the fork grabs the tool shank, taking it from the holder. The fork puts the new tool in position, releasing the old tool.

This is what ultimately allows the CNC to operate without manual intervention.

6. Vacuum Suction Pods and Cover

Vacuum suction pods hold your workpiece in place while using your CNC machine. They are usually made with rubber and use suction to avoid the materials slipping while working. They also allow you to machine the perimeter of the material.

There are loads of sizes to choose from depending on the type of material you’re working with and the workpiece size.

There are also different shapes, like round, corner, and square.

The vacuum suction pod cover goes over the suction pod during the cutting process to protect it from damage while in use.

On the downside, high-quality vacuums are expensive and have a high operating cost.

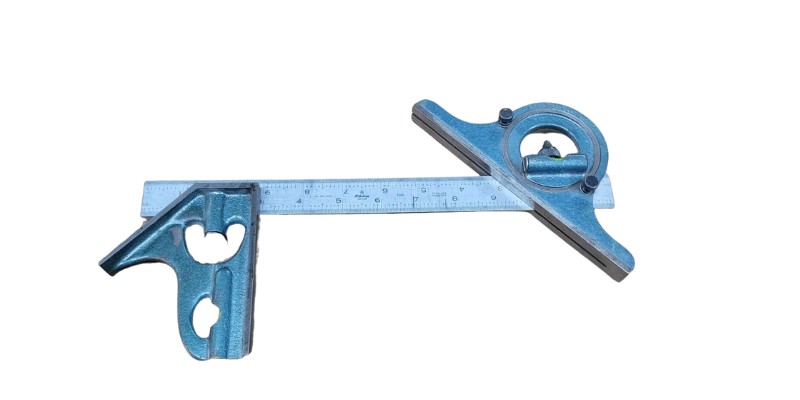

7. Combination Square Set

A combination square is an absolute must-have. It is a measuring tool containing a ruler, level, and protractor to help measure and level materials while you work.

Having all three combined makes things super convenient and can make your job a lot easier. No more digging in the tool shed for different tools. A combination square set has it all in one.

Let’s look at the different components:

- Ruler: This is generally 12 inches long and helps you directly measure materials. It’s useful when you’re configuring the dimensions of the project or want to make 100% sure the CNC machine is set up correctly. The ruler also helps set up drill bits to ensure they’re at the right height.

- Level: You’ll find the level on top of the ruler to ensure it’s straight. This really helps when working on larger projects where measuring gets tedious.

- Protractor: Located on the end of the ruler, the protractor helps measure angles between 0-180 or 270 degrees. You can also find the center of circular cross-sections with it and even test the calibration of your tool and table top.

8. Nylon Sanding Brushes

Nylon sanding brushes are used to sand down materials to improve the finish. So, if you need something super smooth, this really helps.

They work well for materials like plastic, wood, and metals.

Most sanding brushes contain particles like diamond, carbide, or aluminum to help sand away harder materials. So, you’ll select your nylon brush grit based on what you’re sanding down.

The great thing about nylon sanding brushes is that they are far less likely to clog because they’re made to get into crevices and irregular shapes.

They’re also much more precise than manual sanding and help to create a professional, smooth finish.

So, whether you’re edge blending, cleaning, deburring, or polishing, nylon sanding brushes have got you covered.

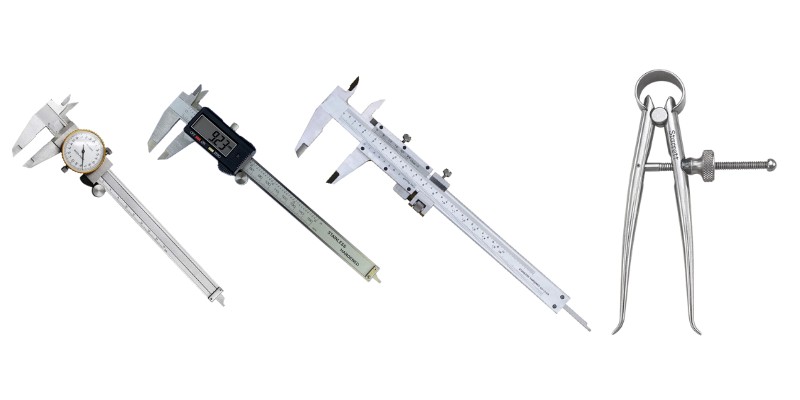

9. Calipers

Calipers measure the distance between two points, thickness, or a gap. They are extremely precise, giving you accurate results every time.

There are four different types of calipers:

- Dial calipers: These have jaws that slide along a beam, measuring the distance of an object. So, jaw A remains on one end while jaw B slides along the beam to the other. You then look at the dimensions to get your measurements. It’s like a ruler but much more precise.

- Digital calipers: These work the same way dial calipers do, with the added benefit of digital reading, so there is no room for mistakes. Some send the measurements directly to your computer, making things even more convenient.

- Vernier calipers: Similar dials, vernier calipers have two sliding jaws but without the dial. You do calculations to figure out the measurements. If done correctly, this is highly accurate.

- Layout and spring calipers: These calipers have two adjustable legs. Inward-pointing legs are for outside measurements. Outward-facing legs are for inside measurements. You measure the distance between the legs with a ruler.

You select your type of caliper based on your measuring and the precision needed. The digital caliper is the best option for precision. It is more expensive, but you can’t put a price on accuracy.

10. Dust Shoes

Dust shoes attach to your CNC router or spindle. They close the cutting area off to prevent dust from flying everywhere.

After all, keeping your work area clean is vital for precision and safety.

If dust gets into CNC machines, you could be in for a world of trouble. It can affect how the machine functions and repairs don’t come cheap.

So, while not a standard component of CNC machines, dust shoes can make a huge difference.

Factors To Consider When Selecting Accessories For CNC Routers

CNC accessories can be a real time-saver. They are precise, convenient, and make your job a lot easier.

However, you need to know how to select the right accessories to prevent unnecessary spending and waste.

Here’s what I think you should look out for when buying accessories for CNC routers.

- Look at the quality: There is no point in putting cheap, low-quality accessories on expensive CNC machines. They wear down quickly and can damage your other equipment. Look for reputable suppliers that make quality accessories.

- Compatibility: The number one thing to consider is whether the accessories are compatible with your CNC machine. Forcing something on can damage the equipment.

- It’s all about the materials: The accessories you need will be based on the materials you work with. Using a CNC wood bit when working with metal won’t help. So, keep an eye on what the accessories are specifically for. Don’t rely on looks alone; many pieces look the same but are made for use on totally different materials.

- Accessories for the end workpiece: If you’re engraving, turning, or cutting, you need accessories that work with what you’re doing. Choosing a CNC drill bit for cutting won’t work for engraving. So, keep the end workpiece in mind.

Final Thoughts

A CNC machine can make your life much easier when shaping and getting precise cuts. It takes the hassle out of measuring and doing the work manually.

CNC accessories are ultimately there to make your job easier, safer, and more precise. So, if you’re in a line of work where measurements are critical, getting the right accessories is vital to success.

FAQs

What bits does a CNC router need?

This depends on the product you’re working on and the materials. If you’re working with wood, you should have a 1/4″ down cut bit, 90° v-groove bit, fattening bit, and 1/8″ bit.

Can CNC router bits be used in a regular router?

Yes, if the router bit is made to cut or carve wood, for example, you can also use it in a regular hand-held router to carve wood. However, the collet should match the router bit size.

Is there a difference between router bits and CNC bits?

Router bits are a particular type of CNC bits. Another type of CNC bit is endmills. Endmills have spiral flutes for cutting, while router bits usually have straight blades.

Can you use a CNC router as a saw?

Ultimately yes, if you’re in a pinch. However, a CNC router isn’t meant for general sawing. You’re better off using a table saw to finish the job quickly and precisely.