Key Takeaways

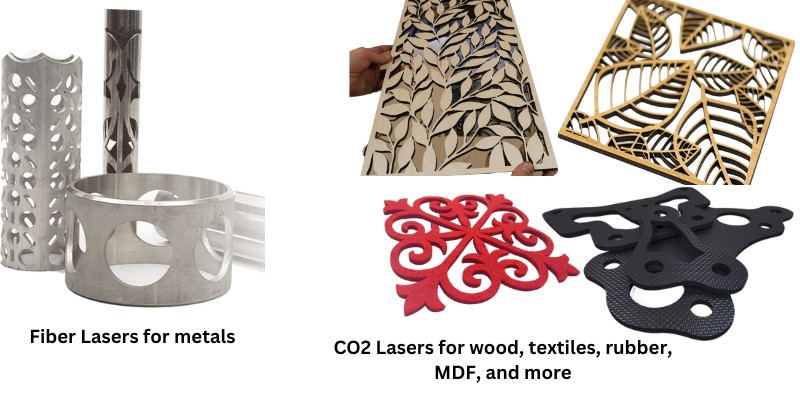

- Laser types: Fiber and CO2 lasers are both laser cutters, but they have different technical and practical features.

- Laser beams: Fiber lasers have shorter wavelengths, higher power density, and higher efficiency than CO2 lasers. CO2 lasers have larger beams and lower efficiency.

- Material compatibility: Fiber lasers are better for cutting metals, while CO2 lasers are better for cutting non-metals. Some materials can be cut by both lasers.

- Cost and speed: Fiber lasers are more expensive, but faster and cheaper to operate than CO2 lasers. CO2 lasers are better for cutting thicker materials and give a better finish.

Overview

Fiber and CO2 lasers are more accessible and affordable than ever – but while they’re both laser cutters, they also differ greatly.

They suit very different materials, so if you buy the wrong type of laser, you’re completely restricted in the projects you can make.

In this article, I’ll compare CO2 and fiber lasers over laser beam differences, materials, efficiency, maintenance, speed, applications, cooling systems, consistency, price, and more. Here are my quick takeaways:

| Aspect | Fiber Lasers | CO2 Lasers |

|---|---|---|

| Materials | Much better suited for metals. Can also cut wood, MDF, cardboard, plastics, rubber, stones, textiles, and more. | Suitable for wood, MDF, cardboard, plastics, rubber, stones, textiles, and more. Can engrave steel and aluminum but not cut them (unless you have an industrial laser). |

| Power Requirement | Lower power and less cooling needed. | High power and more cooling needed with more heat loss. |

| Applications | Jewelry, bar codes, appliances, marking stainless steel, and annealing metals. | Engraving, cutting non-metals, and cutting thick materials. Better suited to general small business tasks. |

| Maintenance Cost | Require less maintenance than CO2 lasers. | Require more maintenance than fiber lasers and the laser tubes need replacing. |

| Up-front Cost | More expensive upfront than CO2 lasers. | Less expensive upfront than fiber lasers. |

Key Differences Between Fiber and CO2 Lasers:

Technical Differences:

- Fiber lasers produce a smaller wavelength.

- Fiber lasers produce a narrower focal point.

- Fiber lasers convert the energy source to the laser beam more efficiently.

- The beam travels in fiber optics in fiber lasers, while CO2 lasers use mirrors (beam path delivery system).

- Light is the energy source for fiber lasers, while electrical pumping energizes CO2 lasers.

Practical Differences:

- Fiber lasers are more expensive.

- For hobbyists and small shops, metals are mostly compatible with fiber lasers and non-metals with CO2 lasers.

- Fiber lasers are excellent for etching and marking (annealing) metals.

- Fiber lasers have a much longer life span.

- Fiber lasers cut thin metals faster in industrial production lines.

- CO2 lasers are still better for cutting thicker metals in production lines and give a better surface finish.

- Fiber lasers have a lower operating cost.

- CO2 lasers require more maintenance.

- If you’re a hobbyist or small business: focus on the material compatibility differences between fiber and CO2 lasers.

- If you’re in industry: focus on the costs and profits differences.

And here’s my opinion on what to opt for if you’re after a cheaper, or more powerful CO2 or fiber laser:

Low-power CO2 lasers:

- Excellent for engraving most non-metals and a few metals

- Can cut thin and soft non-metals like wood, acrylic, leather, rubber, and plastic.

Low-power fiber lasers:

- Excellent for etching and engraving metals and some non-metals

- Can cut thin metal sheets and a few non-metals

- Can anneal some metals and maybe even color-mark

High-power CO2 and fiber lasers for industrial use:

- Fiber laser costs more, but is faster and has a lower operating cost.

- A CO2 laser is better for thicker materials (above ½”) and gives a better finish.

What Are the Differences Between Fiber Lasers and CO2 Lasers?

The differences between fiber and CO2 lasers appear on these levels:

- Technical result: different wavelengths and efficiencies

- Practical difference: effects on materials, maintenance, cost, speed, application, power requirement, cooling, and more

Technical Differences Between Fiber and CO2 Lasers

The different methods of generating the laser beam cause fiber and CO2 lasers to have different wavelengths, focal points, and efficiencies.

Laser Beam Generation

All lasers need an appropriate medium to create the laser beam. They also need an energy source to excite the medium and generate the laser beam.

CO2 lasers use a gas medium, while fiber lasers employ optical fibers.

The gas medium in CO2 lasers actually contains a range of gases, including CO2, nitrogen, helium, and more. On the other hand, fiber optics contain rare earth metals like ytterbium.

Also, CO2 lasers use electrical pumping, while fiber lasers use optical pumping. In other words, CO2 lasers get their energy directly from electrical sources (AC, DC, or radio frequency), while fiber lasers get their energy from light sources.

Wavelength

| Laser Type | Entire Wavelength Range | Typical Wavelength |

|---|---|---|

| CO2 | 9-11 µm | 10.6 µm |

| Fiber | 0.78-2.2 µm | 1.06 µm |

Typically, CO2 lasers can generate wavelengths between 9-11 µm, while fiber lasers produce between 0.78-2.2 µm. Most commercial CO2 lasers have wavelengths of 10.6 µm, while fiber lasers are usually a tenth of that at 1.06 µm.

Fiber lasers have shorter wavelengths than CO2 lasers, and so different materials absorb them differently. Most metals better absorb fiber laser beams, while most non-metals better absorb CO2 laser beams.

Efficiency

Fiber lasers are about three times more efficient than CO2 lasers. While CO2 lasers convert about 15% of the energy source into the laser beam, fiber lasers convert about 42%.

As a result, CO2 lasers need higher input power and more cooling to compensate.

Focal Point and Spot Size

CO2 lasers have larger beams than fiber lasers. Fiber lasers focus their energy on a smaller area, so they have a higher power density.

For example, excellent industrial CO2 lasers may have a beam area of 0.002 cm2, while high-quality fiber lasers affect an area of about 0.0002 cm2.

As a result, fiber lasers can cut thin materials faster since they are like much sharper knives. On the other hand, CO2 lasers are better for cutting thicker materials. Also, CO2 lasers give better-finished edges.

Practical Differences Between CO2 Lasers and Fiber Lasers

Materials Each Laser Can Cut

If you are a hobbyist or own a small laser shop, you can’t cut metals with a CO2 laser. So, you’ll need a fiber laser to work with gold, steel, brass, copper, nickel, tungsten, and more.

For a hobbyist or small shop, the compatible materials become the most important difference between CO2 and fiber lasers: fiber lasers are appropriate for metals, while CO2 lasers or suitable for wood, MDF, cardboard, plastics, rubber, stones, textiles, and more.

There are a few overlaps too. For example, both lasers can cut wood and acrylic, however, CO2 lasers can also engrave wood and acrylic, and give better finishes. We have also written a full article on the materials CO2 and fiber lasers can engrave and cut.

Also, CO2 lasers can engrave steel and aluminum (but not cut them). Overall, CO2 lasers are more versatile than fiber lasers.

Can CO2 Lasers Cut Metals?

Only industrial CO2 lasers can cut metals. Metals absorb fiber laser beams better than CO2 lasers, but they still absorb a portion of the CO2 laser’s beam.

So, you can cut metals with a high-power CO2 laser, but you’ll need a phenomenally powerful 1KW CO2 laser to do so, whereas you can cut metal with a far weaker equivalent fiber laser.

Applications

Lower-power fiber lasers are extensively used for traceability, because they can print ID codes on metals at amazing speeds.

Plus, fiber lasers can engrave, etch, and anneal metals, and mark stainless steel without altering its anti-corrosive qualities.

Low-power CO2 lasers are excellent for engraving or cutting non-metals. Hobbyists and small shops will find CO2 lasers the more versatile machines.

High-power CO2 and fiber lasers are both used for industrial material cutting. They mostly cut metal sheets for production lines. Both lasers can do the job, but depending on the industry, one type is usually more profitable than the other.

Speed: Difference Between Fiber and CO2 Laser

Since fiber lasers are more efficient and have a higher power density than CO2 lasers, they can cut metals faster than CO2 lasers. An industrial fiber laser cuts metals 5 times faster than a similar-powered CO2 laser according to Midatlanticmachinery.

The increased productivity affects industrial lines. However, small shops and hobbyists shouldn’t consider this factor since the compatible materials don’t overlap much in the light lasers.

Material Thickness

We’ve seen how fiber lasers can cut metals faster and with less power. However, as the material gets thicker, the fiber laser’s advantages evaporate.

For metals that are thicker than ½”, CO2 lasers become better than fiber lasers. They are as fast and as powerful at a fraction of the cost.

Once again, this difference doesn’t affect hobbyists and small shops at all – this is only a factor for huge industrial lasers.

Surface Finish

CO2 lasers give a better surface finish than fiber lasers. This becomes more visible in thicker materials. You can clearly see the difference when the metal is thicker than ¼”.

Price

CO2 lasers start at around $3000, and fiber lasers start at around $4000. However, industrial machines can cost $100,00, or even more. Generally, a fiber laser with a similar work area and power will be more expensive than a CO2 laser.

Fiber lasers used to be extremely expensive, but their prices have fallen dramatically over time. Still, fiber lasers are more expensive than CO2 lasers.

Operating Cost

The more powerful the laser, the more important accounting for operating cost becomes. It’s a key factor for large businesses.

The operating cost of a CO2 laser is considerably higher than that of a fiber laser. CO2 lasers are much less efficient in turning the energy source into a laser beam.

Additionally, they need more powerful cooling systems that also consume more energy. Also, the larger laser spot engages more material while cutting and requires more energy.

For example, a 3000W fiber laser requires 15kW of electricity, while a 4000W CO2 laser requires a whopping 215kW, according to Laserphotonics. So, if these lasers work in 12-hour shifts, the fiber laser’s electric bill will be $2700 per year, while the CO2 laser will be $38700.

Plus, the fiber laser requires no maintenance and has no consumables, whereas the CO2 laser requires gas and maintenance. According to Laserphotonics calculations, these bills are about $45000 for the aforementioned CO2 laser.

However, if you’re a small business, even with a 100W laser these cost differences are not much at all. I calculate the overall difference to be under $100 per year for small businesses with low-power lasers. CO2 laser operating costs are slightly higher, and you’ll need to replace the tube every now and then.

Industries need to weigh the CO2 laser’s higher operating cost against its lower price. But, this factor does not impact hobbyists and small businesses’ choice between fiber and CO2 lasers.

Maintenance

The fiber optics in fiber lasers gift several advantages over CO2 lasers’ beam path delivery system. These include beam path maintenance, and laser life span.

You need to clean the mirrors in your CO2 laser’s beam path regularly. However, fiber lasers are practically maintenance-free. Although fiber lasers have lenses that refocus the beam, they don’t have any mirrors for reflection since the beams travel in the fibers.

Also, fiber lasers last a long time. The gas tube in low-power CO2 lasers lasts 4,000-10,000 hours and industrial CO2 lasers may last up to 20,000 hours. However, fiber lasers last 50,000-100,000 hours.

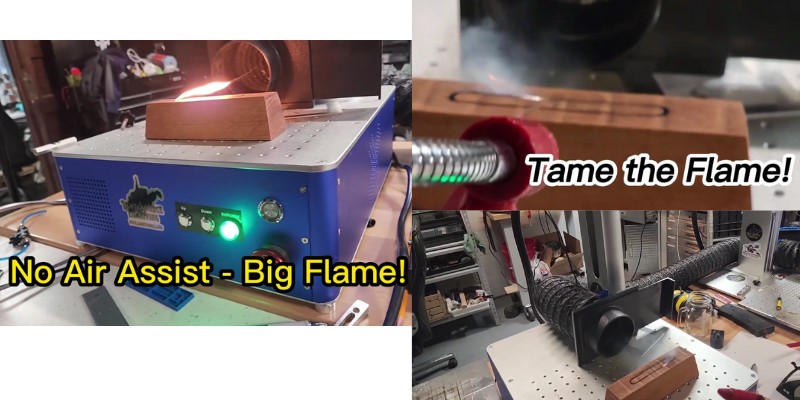

Air Assist

Air assist helps the laser’s efficiency, speed, finish, fire hazard, and more. It’s beneficial to hobbyists, and a must for industries.

While ordinary air assist is excellent for light uses, industries use gas containers like nitrogen or oxygen.

Nitrogen air assist is best for fiber lasers, while oxygen air assist is best for CO2 lasers. This is because nitrogen is excellent for removing small molten material, while oxygen is great for removing larger molten material.

Therefore, nitrogen helps the fiber laser’s narrow beam, while oxygen better helps the CO2 laser’s wider beam.

However, some fiber lasers are equipped with beam shape technology. This allows the user to alter many key components in the laser beam. In this case, the user may also benefit from oxygen air assist, depending on their settings.

Temperature and Cooling System

With lasers, wasted energy is turned into heat. Because they’re less efficient, CO2 lasers get hotter than fiber lasers.

As a result, CO2 lasers require powerful cooling systems. This translates to higher operating costs and possible added maintenance – a disadvantage versus fiber laser cutters.

Warm-Up Time

Industrial CO2 lasers may need to warm up before they can cut efficiently. This can be as high as ten minutes each day. However, fiber lasers are immediately efficient, making for faster productivity.

Consistency

Fiber lasers are more consistent than CO2 lasers. You may have to change your cutting parameters with a CO2 laser over time, but the same settings consistently work for a fiber laser.

Buyer’s Guide: Choosing Between a Fiber and a CO2 laser

The criteria for choosing between fiber lasers and CO2 lasers is different for hobbyists and industrial users, as I explain here:

Hobby Use vs Small Business Use

If you’re a hobbyist or want to open a small business, you’ll only need a low-power laser. Buy a CO2 laser if you’re mostly working with non-metals, and a fiber laser if mostly working with metals.

If you’re looking for a fiber laser to engrave metals, I recommend the Cloudray Raycus 50W Fiber Laser.

Some fiber lasers can even mark metals in color. OMTech’s MP series are excellent fiber lasers for engraving, marking, and color-marking metals. The 60W machine can cut metal sheets too.

Glowforge is one of the most popular desktop CO2 laser engravers. They’re extremely user-friendly, so many small businesses who are newer prefer them. Gweike Cloud Pro is also a worthy alternative, with similar specs but at a lower price. You can also read our article comparing Gweike Cloud vs Glowforge lasers.

However, if you need a more heavy-duty CO2 laser, I recommend a Thunder Laser Nova or a Boss LS CO2 laser.

However, if you want an industrial laser that can cut metal sheets for production lines, you can go either way. You’ll have to solve the cost and profits equation (explained later).

How to Decide Between Fiber or CO2 Lasers for Industrial Use

If you’re a hobbyist or small business owner, you don’t need to read this section.

Material Thickness

If your production line cuts thick metal sheets (above ½”), a CO2 laser will cost less, and give a better finish. Fiber lasers are better for thinner material due to their better speed and lower power requirements.

A 2000W CO2 laser can cut 1” steel and costs up to $40,000-60,000. However, operation and maintenance costs are high.

Cost and Profits Equation

If your production line cuts mostly thin sheets, you should consider the following:

A fiber laser costs more up-front, but they can be 5 times faster, and have half the operating cost.

So, if your production line is busy enough, higher productivity and lower operating cost can make fiber laser’s higher cost worth your while. Otherwise, a CO2 laser requires a smaller investment and can be the more prudent investment.