The best 4 axis CNC routers have better, more flexible manufacturing capabilities – but they’re more expensive than standard 3-axis hobbyist CNCs. In this article, I’ll recommend the best 4-axis CNCs for every use, from basic hobbyist projects to professional small business use:

The Foraver CNC 3040T is my top recommendation for beginners and hobbyists, thanks to its affordability and user-friendly design. This desktop 4 axis router is perfect for home workshops, with impressive versatility for different projects at an unbeatable price point.

If you need something a little more serious the Vevor 4 Axis CNC Router is equipped with a larger worktable and smoother movement for more professional projects – while the JFT 6040 is an industrial pick that can handle anything you throw at it.

The Best 4 Axis CNC Routers

1. Foraver CNC 3040T 4 Axis Router – Best Small 4 Axis CNC

- Price: Check price at Amazon here

- Working Travel: 275mm x 385mm x 65mm

- Spindle Speeds: 8,000 RPM

- Repeat Accuracy: 0.05mm

Pros

Affordable 4-axis CNC router.

Provides great flexibility, accuracy, and efficiency.

Can drill many materials.

User-friendly and small enough to keep in your home.

Cons

Can only be controlled via desktop and isn’t compatible with a laptop.

While it doesn’t offer the quality of other machines, such as the Vevor router we’ll review next, you’d be hard pushed to find a cheaper 4 axis machine than the Foraver CNC 3040T.

It’s specifically designed for hobbyists and first-time beginners, so it’s very user-friendly. It’s also small enough to easily fit in your home or personal workshop.

It’s built with an aluminum alloy frame which ensures the router is very steady, robust, and durable. The cover plates also help reduce the pollution of screws and shafts. The spindle speed ranges from 500 to 8,000 RPM and there is a motor knob for making positional adjustments.

You can use this machine with a wide range of materials, from wood and plastic to stone and MDF, so it offers lots of versatility in terms of projects you can work on.

Overall, the Foraver 4 axis CNC wood router is a user-friendly, robust and versatile machine that offers good value for money.

2. Vevor 4 Axis CNC Router – Best for Small Businesses

- Price: Check price at Amazon here

- Working Travel: 395mm x 600mm x 70mm

- Spindle Speed: 24,000 RPM

- Repeat Accuracy: ≤0.03mm

Pros

High-quality for a low cost.

Worktable is large, providing higher enforceability while engraving.

Comes with a 57 two-phase stepper motor on each axis for easy movement

Cons

Setup can be difficult.

Vevor is one of the most prolific producers of CNC machines and is well known for producing high-quality yet low-cost CNC routers. The Vevor 4 Axis CNC Router ticks both these boxes and is an excellent choice for anyone looking to start a CNC business.

For starters, it’s a very steady and solid machine thanks to the aluminum worktable and backing plate, which are dustproof for easy cleaning. The worktable is large with dimensions of 750x480x15mm, providing higher enforceability while engraving.

The chrome shafts are also very well designed, while the cover plates protect the screws and shafts from pollution, so the machine has a long working life and can be used continuously without damage.

This 4-axis kit comes with a 57 two-phase stepper motor on each axis for easy movement. The motors are connected using reliable external couplings, which produce high torque transfer. You can also easily adjust the position of the motors using the knobs on the side of the machine.

The spindle motor on the Z-axis is water-cooled and capable of reaching up to 24000RPM/min for accurate, high-performance machining.

Another nice feature is the functional controller that comes with a built-in transformer. The controller is intuitive, has an emergency stop button, and the transformer helps provide stable power over long-term use. You can also connect the router to your computer via the USB port and easily control it using Mach3.

3. JFT 6040 – Best for Industrial Use

- Price: from $4,434 — Available at Amazon here

- Working Travel: 400mm x 600mm x 100mm

- Spindle Speed: 24,000 RPM

- Repeat Accuracy: 0.03mm

Pros

Excellent speed, power, and accuracy.

Multiple wattage options for each axis are available.

Cons

Steep learning curve and is not suited for beginners or casual hobbyists.

JFT has taken a somewhat unusual approach to its products by making the same model available in 3 axis, 4 axis, and 5 axis formats, with different wattage options for each.

This certainly offers a great degree of choice when it comes to finding the right machine for your needs. The 4 axis version is available in 1.5Kw and 2.2Kw, with the latter costing around $200 more.

As the price reflects, this JFT 4 Axis CNC Router is designed for use in industrial settings. It’s a very stable, robust, and durable machine with high-strength ball screws, while the spindle can reach speeds of up to 8,000mm/m. This speed and power make for great accuracy, even during continuous use and for demanding projects.

Like the Vevor 4 Axis CNC machine, the JFT model has a USB port so you can control it via your computer using the Mach3 software. Mach3 is regarded as one of the top CNC control software solutions and is very intuitive, so it’s easy to get the hang of.

If you’re a business owner or industrial worker looking for a reliable 4 axis milling machine, this is certainly a model worth considering.

The Low-Down: Is It REALLY Worth Getting a Fourth Axis?

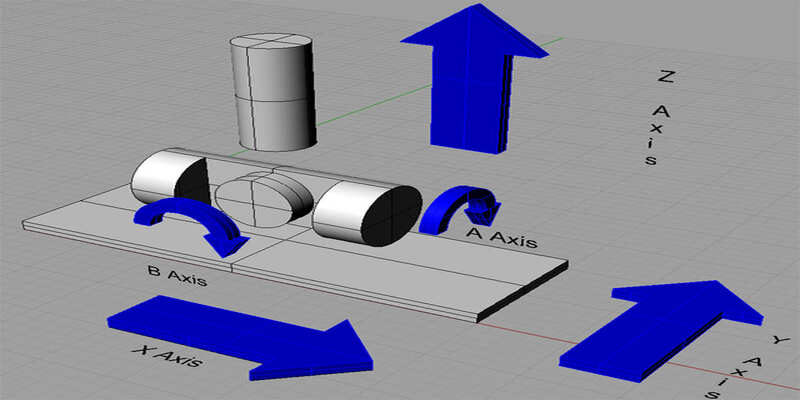

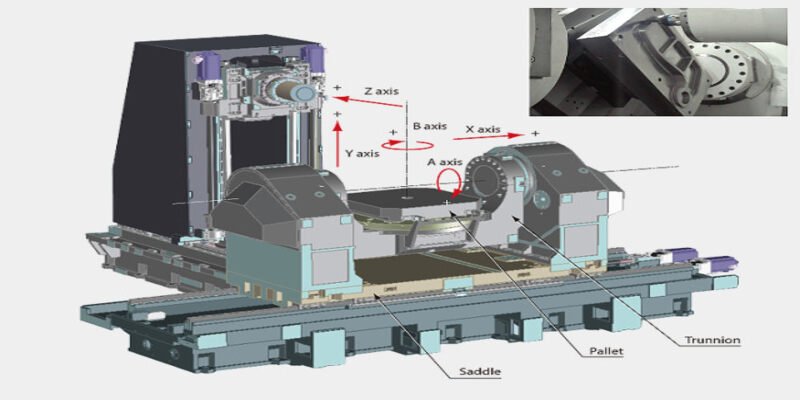

Most hobbyist CNC routers have three axes, while 4 axis CNCs simply have an additional rotational axis to provide more efficient and versatile machining.

A 3 axis router has X, Y, and Z axes for cutting flat 2D and 2.5D shapes:

- The X-axis moves left to right

- The Y-axis moves right to left

- The Z-axis moves up and down

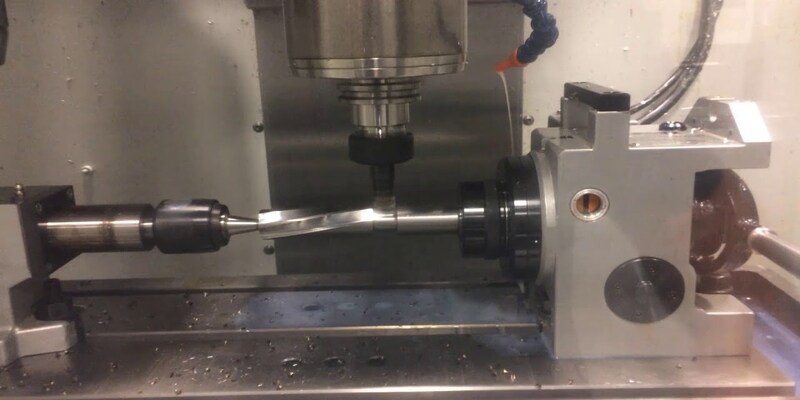

Whereas 4 axis CNC routers also have an A-axis, also known as the rotary axis.

This not only makes a 4 axis CNC router more efficient than a 3 axis, but it means you can more easily work on more complex jobs. With a 4 axis router you can work on four sides of a workpiece in a single fixture setup, which you’d require multiple fixtures for on a 3-axis machine. This means more time, more energy, and lower accuracy due to the loss of tolerance caused by fixture changes.

Pros and Cons To Upgrading To A 4-Axis Machine

There are some other specific benefits of having a fourth axis, for example, you can drill on the side of parts on cylindrical surfaces. You can also machine angled features.

Advantages

- The rotary axis makes them better for jobs like furniture and musical instruments than 3-axis machines

- Higher quality, efficiency, and flexibility

- Considerably less expensive than 5 axis routers while being capable of creating lots of the same products

Drawbacks

- Much more expensive than 3 axis machines – beyond the budget of some hobbyists

- Cannot create extremely complex objects (you still need a 5-axis CNC for these)

- Fewer options on the market, as not all are compatible with the rotaries

If you have the budget, you can also upgrade to a 5-axis CNC with an extra B-axis for even more complex projects typically used in industrial settings.

Applications

A 4 axis CNC machine can be used for the same basic applications as a 3 axis one, such as for sign making, jewelry engraving, arts and crafts, home decorations, and so on. However, due to the rotational A-axis, they can also be used for working on more complex products.

For example, one of the most common uses of 4 axis machines is carpentry, where they’re widely used in the industrial production of cabinets and furniture. However, they are also often used in the manufacturing of more intricate products, such as musical instruments.

4 axis CNC routers can be used with a wide range of different materials, such as plastic, wood, acrylic, PVC, PVB, MDF, stone, ceramic, and more. You can’t use them to engrave or mill metal, but if you’re using the aforementioned materials, then there’s a huge range of possibilities with a 4 axis CNC router engraver.

For further reading, read our guides to:

- The difference between 3, 4, and 5-axis CNCs

- The top laser cutters with rotary attachments (fourth axis)