For many, starting a CNC business is a dream job. You get to spend your days doing something you’re passionate about, with the potential to earn far more than you would in regular employment.

I know dozens of people – myself included – who have been able to turn their hobby into a thriving business, and while it is incredibly satisfying it is certainly not easy.

- Why Start A CNC Machining Business?

- CNC Machining Startup Costs

- Market Research

- Identify Your Unique Competitive Advantage

- Choosing Products That Will Sell

- Analyze your competitors

- Stay on top of trends in CNC (and new technology)

- How to Sell Your Products

- Other Ways to Market Your CNC Business

- CNC Tool and Machine Mastery

- Reinvesting in Your Business

- Expanding Your CNC Business Through Investment

- FAQs

- Final Thoughts

It takes a lot to be successful in this game – and I’m here to walk you through the whole process so you can skip the common beginner mistakes.

There’s a lot that goes into running a CNC business that you might not have considered. You’ve got to have a solid plan for:

- Your start-up costs (machine and materials)

- Market demand (do people actually want what you’re selling)

- Pricing and margins (to make sure you can make a profit)

- Marketing (how are you going to get eyeballs on your product or service)

- Fulfillment (using systems to make sure you can deliver on your promises)

Now, that might seem a little daunting, but it’s all manageable if you just take it one step at a time. I’ll cover it all in this guide.

I’ll set you on the right track to making at least $1000 per month with your CNC business, and then we’ll touch on the next steps for scaling your project with staff members, workplace expansion, and outside investment.

Why Start A CNC Machining Business?

CNCs (including even lower-cost CNC routers) can now easily create complex designs and shapes, from home crafts to office supplies and kitchen implements to original signage, games, and toys.

CNC makers have total freedom to create products that are personalized and different, which makes them very popular on Etsy, Facebook Marketplace, eBay, Amazon, and independent brand e-commerce stores.

You’re not limited to a certain material, either: you can work with wood, plastics and acrylics, glass, and metal (with a strong enough CNC).

CNC products are also popular on social media platforms like YouTube and TikTok. At the press of a button, you can now showcase your designs to a worldwide audience, growing visibility and sales.

Beyond selling products to consumers directly, you can also supply products and parts for manufacturing businesses. Aerospace, automotive, medical, and electronics industries all rely on the type of high-quality, specialized components that CNC machining can produce

CNC Machining Startup Costs

First, let’s list some of the considerations you need to make to run a successful CNC machining business:

- Equipment: CNC machines, tooling, and work-holding devices.

- Facility: building construction or rent, utilities, and insurance.

- Employee: wages and salaries for machinists, IT, and administrative/financial staff.

- Raw materials: purchasing and stocking of materials.

- Hardware and software: office and workshop computers, internet, CAD/CAM software, and simulation tools.

- Tools and consumables: drill bits, cutting tools, lubricants, etc.

- Marketing and advertising: user research, market research, website design, and promotion of the business to potential customers.

- Legal and professional: obtaining licenses, permits, and other professional services.

When you’re starting out, the two key factors you’ll need to produce your products – consider are the machine you’ll be using, as well as the materials you’ll be using for your workpieces.

That’s the core of your business. After that, you’ll look to find ways to increase your output – either through automation techniques or delegating tasks to members of staff. But that comes later!

Choosing the Right Machine

The CNC machine itself will be your biggest outlay in the beginning. Depending on the machine, this can range from a few hundred dollars to hundreds of thousands of dollars for high-end machines.

Then there is the tooling, CNC software, and additional accessories you’ll need to consider to make things fully operational.

If you’re just starting up, you could consider outsourcing your CNC tasks to local shops to begin with, rather than investing in a CNC right away. You might only break even on your projects, but you’ll be able to assess how viable your idea is before taking any risk.

Where possible I highly recommend trying to borrow someone else’s machine for your first month or so, whether it’s a friend’s, a friendly company, or at a makerspace/hackerspace.

When you’re ready to invest, I highly recommend buying a used machine rather than a brand-new one to save on initial costs, and upgrade as you start profiting from your business. There are machine shops closing down all the time, and looking for machine shop auctions in your area is a great way to find a used CNC for cheap.

In terms of the machine itself, a used Haas machine would be an excellent choice. They’re powerful, easy to run, and are built like a tank. A used Haas machine will also hold its resale value, so you won’t lose much if you change your mind about getting into this business.

You can learn more about the best CNC machines for small businesses in our full guide – but whichever CNC you choose, consider the type of work you will be doing and how much of it you plan to do – so you don’t overspend.

You can easily start with a cheaper, less powerful and smaller CNC machine, and build up to large router or milling machines as you build your income.

Whatever your needs are, try and keep them focussed. Working with a tighter range of materials and product types means you don’t need as much different equipment, and there’s less of a learning curve for you (or any teammates).

P.S We have full guides for the best CNC routers for all of the most popular materials, including aluminum, and woodworking projects. Also, if you need to broaden your understanding of CNC technical terms, we also have a comprehensive guide on CNC terminology to help you.

Dust Collection

I cannot stress enough how important it is to invest in a good dust collection solution.

It’s not just about keeping the workspace clean and tidy. The dust generated during the CNC process can wear out your equipment quicker, cause respiratory issues, and even lead to fires if left unchecked.

A vacuum cleaner simply won’t cut it if you plan on using your CNC machine for business purposes. You need a much bigger and better solution to effectively capture and filter dust particles. Trust me, you’ll thank yourself later if you invest in this early on.

I recommend a dust cyclone system connected to an impeller (~2HP) and 100mm (4″) piping, connected to a canister filter (preferably ~0.3-0.5 micron).

Additionally, at the spindle, it’s important to have a good dust shoe with compressed air to blow out the wood chips. This is because the 100mm piping will have low pressure but high volume, so it won’t be able to suck with as much power as a shop vac up close.

This is the system I use in my workshop, and while it may seem like an unnecessary cost when you’re just starting out, it’s going to save you money replacing damaged equipment in the long run.

Market Research

Market research is key when starting a CNC machining business. It’ll help you identify the potential demand for your products or your services, and help you understand the current industry trends. Some potential areas to research in the CNC industry include:

Market demand

Research which parts and products are most in demand in your target industries and your local market. Identify the customers that need CNC machining services and which applications they need most. This will vary depending on if you’re targeting B2B (local businesses as a service), or B2C (selling custom products to customers on Etsy or similar).

Industry trends

Keep informed about the latest industry trends. Watch emerging technologies, processes, and materials. Be aware of new standards, certifications, and regulations. For example, AI is almost certainly going to be built into CAD/CAM software over the next year, so learning good prompting for design will save you an enormous amount of time designing in the future.

Supply chain analysis

Make sure you’re familiar with how the supply chain of the CNC industry works. Research the manufacturers and suppliers of machines and raw materials. Look into potential suppliers that could reduce your costs, and think about how your workshop layout can be improved to make your processes more efficient.

Industry associations

Join CNC industry associations, both local and national. Attend events and trade shows. Get networking to advance your knowledge on best practices, technology innovations, and the latest industry trends.

User / Customer Research

Knowing your customers is an essential part of not only the CNC product development process but also understanding who your target audience is.

Applying some of the following steps will give you a better idea of these important requirements:

- Identify your target audience: Before anything else, you should have a clear idea of the audience you’re targeting. Perhaps you’re using your CNC machine to supply shelving, furniture, wall art, or candle holders for a domestic customer base.

- Conduct surveys: Conducting surveys can gather invaluable feedback from users. Structure survey questions to identify your target market’s preferences, pain points, and needs. Also, find out how easy it is to use existing products. This kind of feedback can provide better direction regarding design and service requirements.

- Carry out interviews: Interviewing your target audience gives you more in-depth insights about what your users actually need, and what they would prefer from your products or services. You can do this face-to-face or remotely, and either speak to a single person at a time or as a group.

- Analyze the data: Once you’ve collected the data from your user research, analyze it to identify important trends and patterns. Identify the main preferences, needs, and common pain points among your target audience.

- Build a user persona: Once you’ve analyzed all your data, you can build your user persona. This is a profile of your typical user, their age, demographics, buying habits, and personal needs – this is who you’ll focus on marketing to.

Use these insights you’ve gained through market and user research to find anything you can improve in your process, marketing, or whether you need to pivot to a different niche within CNC manufacturing.

Identify Your Unique Competitive Advantage

I’ll cut to the point: the CNC market is oversaturated.

It is easy to fall into the trap of thinking that you can open an online store, sell whatever you like, and become wealthy overnight.

You’ve seen guys on Youtube talking about how much money they’re making – sounds easy, right?

In reality, there are companies selling similar products for insanely low margins, and producing them far faster than you possibly could.

To convince someone to give you their money instead of a competitor, you need to identify a reason why they should.

You’ll have a chance to succeed if you can beat the competition in one of three areas

- Price

- Speed

- Quality

As a one-man army, you’re very unlikely to be able to compete on price. You’re battling against huge businesses that can buy their materials in bulk and outsource their labor incredibly cheaply. Do not try to match their margins.

And given the difference in machinery and infrastructure you have available compared to these huge corporations, you won’t win on speed either, unfortunately.

So that just leaves quality where can stand out and add value to the consumer

Quality is a broad term, but in this case, I’ll summarize it as something that people just can’t get elsewhere – which is either going to be something hyper-specific, or personalized so it is unique.

If people can’t get what you’re offering elsewhere, of course it’s the best quality option available – because it has nothing to compete against!

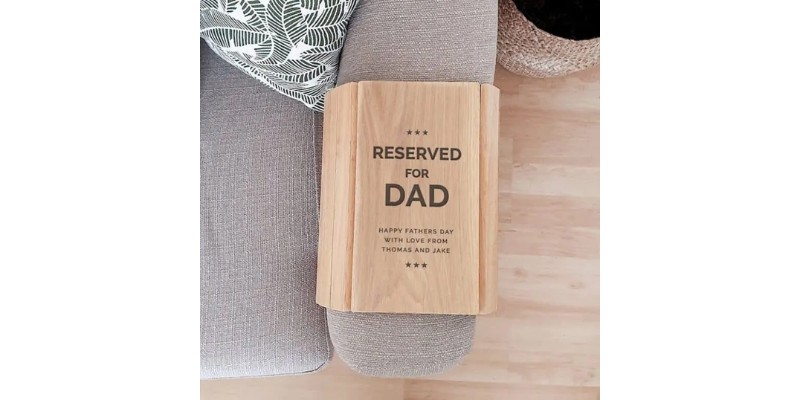

The best way to produce CNC products that sell as a beginner is to use your CNC expertise and design skills to produce one-of-a-kind products that your customers cannot find elsewhere.

Choosing Products That Will Sell

When it comes to deciding which products to focus on for your CNC business, you have to start by identifying a genuine need among potential customers.

Consider what problems you or others around you have that could be solved with anything a CNC machine could make. We’re looking for the intersection between the type of items you’ll be happy to work on every day, and what people are actually willing to pay for!

While there may be competitors with larger machines and cheaper labor, you can set yourself apart by offering a unique product that can’t be easily found elsewhere.

Remember, the CNC machine itself is just a tool – the real value lies in the product you create with it.

Pick Something You Can Build a Range Around

It’s much easier to convince people who have already bought from you to buy again than it is to find new customers.

So, your focus should be on giving your customers a good experience, and then retargeting them with other products they might be interested in.

Be specific, because you’re going to have to brand this at some point. Think about products that consumers might buy together to increase your average order value (AOV).

Repeatable Products

It’s also worth considering the potential for scalability and the opportunity to produce large quantities of a particular product.

The more repeatable the production process, the more efficient you can be, ultimately leading to increased production output and profitability.

One way to achieve this is by choosing products that have a consistent design and require minimal setup changes between runs. You do NOT want to be using new equipment, tools, or software for each individual order – keep things consistent.

This is much more scalable than a business that relies on producing original custom art for every order or having to adapt to a new material type for each engraving.

Pricing

When it comes to pricing your CNC-produced products, it is important to strike a balance between pricing and production efficiency. You don’t want to spend too much time and effort on a product if the profit margins are too low.

That’s why I recommend personalized products where you can charge a premium price. You get rewarded in line with the unique value you can bring to the market, and customers are willing to pay extra for something that’s tailored to their specific needs and tastes.

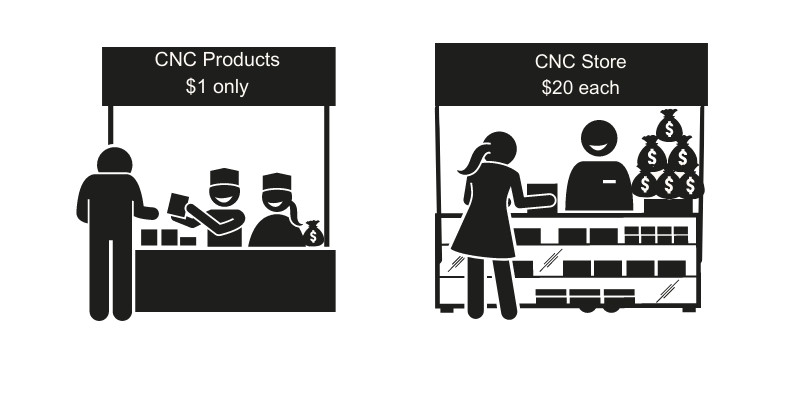

You’re going to need to sell relatively expensive products to generate enough margin to make a good income – so make sure your core offer is at least $50 per product.

Trust me, no one ever got rich making $1 per sale from $10 products. You just won’t have the resources you need to sell enough products to make a living if you’re lurking in the bargain basement.

So that’s your core offer – but even with that in mind, you’ll want to consider a couple of cheaper add-on products that your ideal customer might also be interested in adding to increase your average order value.

Analyze your competitors

Analyzing your direct and indirect competition in the CNC industry is complex and time-consuming, but essential for learning how to market your business, and shows you what’s working well for them.

- Identify key players: Research the key international players within the CNC industry. Companies like Haas, Mazak, Okuma, and some others may not be in direct competition as they manufacture CNC machines, so these aren’t as useful to study. Instead, if you’re starting a CNC service, investigate successful machining services close to you.

- Marketing research: Look at their websites, social media, public client lists, SEO strategy, and lead generation forms. Note what looks good, and what looks to be working well.

- Research pricing: See what your competition charges, and whether you can realistically compete here (or if you need to compete on quality, or in another area instead).

- Look at competition trends: Look closely at those of your anticipated direct competition and see how these may have changed over time. This will give you insights into whether you can expect increases or decreases once you begin trading and into the future.

- Assess market share: Look at the market share of your direct opposition. You’ll get a better idea of which businesses are dominant, and what they’re doing right that got them there — so you can replicate this.

- Consider the competition’s customer base: It helps to know what customers your competition is focused on. Logically, if they’re direct competitors of yours, you’ll want to convince some of those customers to move across to your business.

Try to understand your competition and their pricing and systems. In that way, you’ll be more informed regarding strategic planning and when you buy and sell, or operate as direct competition on projects.

Stay on top of trends in CNC (and new technology)

Staying on top of CNC machinery technology lets you get more efficient, and provide the highest-quality products and services. In this way, you’ll stay competitive within the industry and cater to your customer’s ever-changing needs.

Consider the following to grow and maintain a foothold in the CNC machinery sector you choose:

Reduce potential damage through upgrades

CNC machinery is evolving all the time. Upgrades, such as to a vacuum table, for example, reduce any chance of collision with workpiece holders, and is better for keeping your machines in good shape as well as health and safety.

Enhance speed and scope with multi-axis, modular machinery

Multi-axis CNC laser cutting, milling, and waterjet machines are getting cheaper as technology improves. The best multi-axis CNC machines can cut two parts at the same time, while others can cut and perform another task like boring simultaneously.

Granted, one of these machines may still be too costly for a small business, but it is worth staying on top of the technologies.

If you are able to utilize more axes in workpieces, you’ll reduce the time of setting up your machine and can tackle more complicated tasks (that are often the most profitable projects).

Improve machine performance and lifespan

Sensors have become more efficient and affordable, with many companies in the CNC industry incorporating them into their current systems. This helps increase the performance and lifespan of the machines.

By connecting CNC machines to the Industrial Internet of Things (IIoT), businesses can take advantage of a network that combines both software and hardware. This allows them to share and use data more effectively, ultimately improving their operations. If you have a CNC business, you can likely benefit from using IIoT technology for your sensor and data-sharing needs.

How to Sell Your Products

If you’re new to selling CNC products, I recommend getting started with Etsy.

It’s a super easy platform designed for selling custom-made products, with a good stream of built-in traffic to help you get some initial exposure and acquire your first few customers.

From there, you can look to build out more “sophisticated” marketing strategies (more on that in a second), but for now, the name of the game is gauging demand for your products and getting the ball rolling with your first few sales.

You can have your first few listings up within an hour or so – and it’s a really good way to test the waters.

The feedback you get from customers around pricing, quality, and ideas for new products or tweaks to your existing offer can be really valuable before you go ahead and invest a load of time and money in your own website or a paid marketing campaign.

My Top Tips for Etsy

1. Run Sales

I generally find that running sales on Etsy helps my listing get more exposure and generate more sales, so I recommend pricing your products a few dollars higher than you would otherwise and running frequent promotions (somewhere between 10-20% off is enough)

2. A Picture Says a Thousand Words

It’s really important to take high-quality photos of your products to help them stand out on the search page.

Professional-grade camera equipment will get you the best possible results, as well as staging “action shots” of your products to help your customers get a real sense of how they look in real life.

- Photograph in natural light – Using natural sunlight assists with soft lighting that can improve how your item looks. Try capturing images outside or by an open window. Starting with good lighting means you won’t need to use flash on your camera. Camera flash creates harsh lighting with dark shadows and an unnatural appearance.

- Creatively compose your images – Capture multiple images in different environments to find the best setting to showcase your item.

- Take different types of shots – To showcase your products, you can take different types of photographs to show it in different settings and contexts.

- Leave space around your items – Take your picture from a far enough vantage point where you can see the entire product with extra negative space around your product. This will help when you crop the thumbnail of your listing photo.

- Take photos horizontally – When you upload your photo, a horizontally oriented picture means you’re able to use more of the available space within the thumbnail frame. Vertical images will require more information to be cropped out.

- Clean your camera lens – A dirty camera lens will prevent the ability to capture crisp images that properly focus on the product.

- Try not to zoom – Using the zoom feature on mobile devices and cameras usually results in a digital zoom, which produces a lower-quality image being captured. Instead of using zoom, physically move closer/further away from your item.

3. Optimise Your Titles and Descriptions

You also need to make sure your titles and descriptions follow best practices so that your items appear earlier in search results. Make sure to include all the relevant details in your product descriptions, such as dimensions, materials, and colors in your listing, because customers can search through categories based on these criteria.

(Check the Etsy Sellers Handbook for their official recommendations to have the best chance of attracting more eyeballs).

4. Work Out Your Shipping Systems

Last but not least – fulfillment. At the end of it all, you have to get your products in customers’ hands.

Packing, shipping, and dealing with customers can be a time-consuming and challenging part of running an Etsy shop.

Like producing the products themselves, the easy way to take the pain out of shipping is through a repeatable and systemized process.

I like ordering my packaging supplies in bulk to save time and money, and schedule my deliveries for home pick up a couple of times per week so I’m not always taking trips to the Post Office.

Other Ways to Market Your CNC Business

When you’re ready to take the next step, there are a number of other ways you can invest to grow your new CNC business.

Some more advanced ways you could consider marketing your CNC brand include:

Build a professional website

A top-class website that stands out is a great place to start your marketing efforts. It should aesthetically appeal to visitors, while also being easy to navigate. Provide them with relevant, authentic information about your product and services, as well as your personal backstory (and if applicable, your team’s). Include any awards you’ve won, any publications you’ve featured in, and anything else that builds trust, such as a Trustpilot or other score.

Use search engine optimization (SEO)

If your target audience is searching on Google for local suppliers or businesses, you want to show up first. For local SEO, make sure you have an optimized NAP (name, area, phone number) on your Google Business Profile, and build citations on local directories and industry directories.

And for more general content, create content around the keywords your customers are searching, but also be realistic in what you target — you’ll unlikely outrank Haas for CNC questions as they’re a huge brand with a strong backlink profile. Try to get links from your partners and suppliers, and make sure your site loads fast and is mobile-friendly.

Develop targeted marketing campaigns

With the user research you’ve carried out, devise marketing campaigns. These should speak to your audience’s needs and desires implicitly. Targeted online advertising, direct email campaigns, and website landing pages are all effective for the right audience.

Use social media

Social media platforms like Facebook, Instagram, LinkedIn, and Twitter can be effective marketing tools. Share photos and videos of your work and processes, and post updates about your current projects and your capabilities. Engage with potential customers via forums, groups, pages, and threads to generate further interest in your brand.

CNC Tool and Machine Mastery

A CNC machinist needs to be a highly-skilled technical operator. You’ll need skills in areas like product design, CNC programming, planning, and quality control. Add the right blend of creativity, reasoning, time management, and problem-solving to the mix — and you’ll be an exceptional CNC machinist and manager of staff.

As you develop your skills, you’ll be able to competently produce more complex designs that you can charge more and achieve a better margin with.

The following traits and skills (among others) will help you and your employees to be successful in the CNC field:

Desire

Before you’ll be successful at anything, you need the desire to master it. Without the desire to do something properly, you’ll likely not excel. The other skills and traits on this list won’t matter as much without desire. You need to set yourself high standards and hold your team to those same standards.

Practical aptitude and abilities

As a CNC machinist, you’re going to need to handle tools and display an understanding of the principles of engineering. You may need specialized knowledge of certain CNC machining. Without the aptitude and practical ability, it’ll be very difficult to familiarize yourself with the machine or your role.

Math skills and knowledge of software

You’ll also have to be able to make sense of numbers and math problems to understand models and drawings. You’ll also need expertise in CAM and tool path strategies. You’ll often switch offsets in diameter, for example, to keep the size of cuts exact. You’ll also need to understand CAD, simulators, quality control, audit tools, and file management, among others.

Concentration and attention to detail

As a CNC machinist, you will need to concentrate. The world around you may be going mad, but your single-minded focus on what you’re cutting is needed. You should have the ability to envisage potential problems to make you a great machinist.

Listening to advice and solving problems

If you’re able to identify problems and solve them on the fly, you’ll succeed. It’s all part of the learning curve, and if you have the aptitude for the work, you’ll pick this skill up quickly. While it’s important to solve problems well, listening to co-workers is essential.

Reinvesting in Your Business

First and foremost, the most important investment you can make in your CNC business is making yourself more available. Your first goal should be to use the profits of your CNC business to make a living, so you can decide whether you want to quit your job and dedicate more of your week to growing your enterprise.

Once you’re full-time on your entrepreneurial grind, there are a number of other steps you can take to increase your output and scale your income even further.

The three main levers you can pull are:

- Equipment – High-quality equipment and tools will increase efficiency and reduce downtime.

- Building a team – Hiring reliable and skilled people will allow you to increase output, and buy back more of your time to work on the business, rather than in it.

- Workspace – Expanding into larger premises, or optimizing your layout to improve workflow and minimize wasted space.

Equipment

When choosing the right time to buy, consider the potential time-saving benefits that the equipment will provide.

A basic CNC machine can be a good stopgap to cover you across a variety of tools, but if you have the capital it’s a good idea to invest in purpose-built tools for more efficient machining.

For instance, you can plane materials by running a surfacing pass on your CNC, but it will take longer, and the final “straightness/squareness” will depend on the flatness of your cutting surface and the calibration of your CNC machine.

And while you can get away without a bespoke joiner if you’re working with thinner woods, you’ll need to invest in the proper tool if you want to graduate beyond that.

The right tools will give you better results and free up your CNC machine for simultaneous tasks.

On that note – CNC machines can be quite slow, and detail work can take hours per piece. So even if you decide you really need a joiner or planer, you might just consider investing in another CNC machine anyway to increase your output.

However, if you find yourself needing square stock, and it takes too much time to wait for either your CNC or your turn at the planer, then it might be time to invest in additional equipment.

Staff

As your CNC business grows, you may find yourself in need of extra hands to keep up with the demand. But when is the right time to hire new staff?

One sign is when you start turning away work due to lack of capacity, and or are consistently struggling to find time for important tasks like customer care, inventory management or packaging orders.

When it comes to hiring, experience is important, but so are soft skills. Ideally, you want someone who not only knows their way around a CNC machine but also has good communication skills, can work well in a team, and is open to learning new things.

When evaluating potential hires, ask about their previous experience working with CNC machines, and ask them to demonstrate their skill – we can all bluff in an interview, but a trial day doesn’t lie.

In addition to technical skills and communication abilities, it’s also important to consider the individual’s work ethic. CNC work requires attention to detail, patience, and persistence. A good candidate should be willing to put in the effort and time required to ensure high-quality results.

Workspace

As your CNC business grows, you may find yourself running out of space in your home workshop or communal workspace. While these spaces may be convenient and cost-effective in the early stages of your business, they come with several drawbacks that can limit your potential for growth.

Working from a home workshop may seem like an attractive option for cost savings, but it can lead to distractions and interruptions that can hinder productivity. There are safety concerns to consider when working with heavy machinery which may not be adequately addressed in a home workshop.

Similarly, communal workspaces may have limited access to equipment and resources, which can impact your ability to complete projects on time.

To overcome these limitations and take your CNC business to the next level, it may be appropriate to expand your work premises and move to a dedicated warehouse.

With a larger workspace, you can increase your production capacity, take on larger projects, and improve overall efficiency, leading to increased revenue and profitability.

When considering a move to a larger workspace, it’s important to consider the location, size, and layout of the new facility.

You’ll want to ensure that it’s easily accessible for your employees, suppliers, and customers, and that it has sufficient parking and loading/unloading areas for your equipment and materials.

Expanding Your CNC Business Through Investment

If this is your first CNC business, I strongly recommend starting small. Save up a little, and invest that money in the essentials and grow at a manageable pace.

If you’re up and running and are having some success, you may consider trying to find some outside investment to turbo-charge your growth.

For that, you’re going to need a compelling business plan.

Lenders or investors need to see you’ve got some business sense and will invest the money prudently, and understand the expected returns for that investment.

This means drawing on all the research you’ve done and collating it into a single document that inspires trust.

Let’s take a look at what you should include:

Who Are You?

- Executive summary: You should open your plan with an executive summary. With this, you provide an overview of your CNC machining business, including a mission statement, financial projections, and proposed target market.

- Company description: Your company description should detail the types of CNC machining services you’ll offer, the products you’ll make, etc. Don’t confuse people with jargon and nonsense — try to explain everything as simply as possible, but without sacrificing detail. Also, mention the potential location of your CNC machining business. Include anything from your working history that will support your suitability to run a small business or a large one — investors need to trust your expertise and that you know what you’re doing.

What Do You Offer?

- Research and analysis: The research you’ve done comes in handy now. You should include the results of the analysis you’ve done from your research into the CNC market and its trends, your competition, and your target audience.

Detail the type of research you’ve carried out, and summarize how it leads to your confident projections as a result.

This is an important part of your business proposal. It shows financial institutions or potential investors how thorough you are as a business owner. - Services and products: Describe in detail the specific CNC services and products you’ll offer.

You might be manufacturing prototypes for business or custom parts through a custom manufacturing shop. If you are going to involve your business in the design of products for customers, mention this fact.

List and define any other services, such as consulting for manufacturers, that you also intend to offer.

How Are You Going to Execute?

- Marketing and sales: Show how you’ll reach your audience and how you plan on keeping them once they’ve approached you.

Provide insight into your website, your online marketing, and your physical marketing. Define your brand in detail and add samples of promotional materials and links where possible.

You need to convince those reading your plan that you’re in the process of founding a successful CNC machining business. - Operations and management: Banks need to know about your plans for hiring and any other processes. Also show how you’ll be able to manage your team efficiently.

Give a detailed breakdown of the technology and equipment your new business will have. This way you’ll provide insight into the quality of work you’ll be able to produce.

Money Makes the World Go Round

- Financial projections: You’ll want to be as detailed as possible here. Include startup costs, cash flow projections, and profit and loss predictions over the next years, and any existing figures if you’ve already started the business.

Showing you’re organized and fluent with the numbers is the most important thing you can do here. And be precise. - Funding requirements: Give an outline of why you need the amount, and show exactly how you plan to use the money. Again, being precise is essential. A last tip on this point: make sure you include details of your business bank account.

FAQs

Do I need any special certification or training to start a CNC machining business?

No, you don’t need any formal training or certification to start a CNC machining business! Though, if you have experience in engineering, machining, or a related field, this will definitely come in handy. You’ll likely have to apply for a business license and any local permits to operate heavy machinery, and you’ll also need a taxation number.

What are some challenges I could face if starting my own CNC machining business?

A common challenge you might face when starting a CNC machining business is finding skilled employees and retaining their services. It can also be challenging and expensive to keep up with the latest technologies and equipment while managing cash flow and costs.

Plus, it can be demanding to balance the production capacity of CNC machining with customer demand.

How do I find customers for my CNC machining business?

Network with other businesses and attend trade shows and industry events. Create an online business presence on social media and through a website. Keep your services excellent, and your pricing competitive.

Final Thoughts

Starting a successful CNC machining business requires careful research and planning. You’ll need to identify your direct competition, your target market, and your services and pricing structures, plus you’ll also need to know how much does a CNC cost. Follow this by developing a market strategy based on the findings of your research. Only then should you select the equipment you need and identify your future staff.

Establish a business proposal and approach financial institutions or investors – be sure to include your skills and certifications.

If there’s any way we can be of assistance from the beginning of the process to the end, feel free to contact us and we’ll guide you through CNC machining.