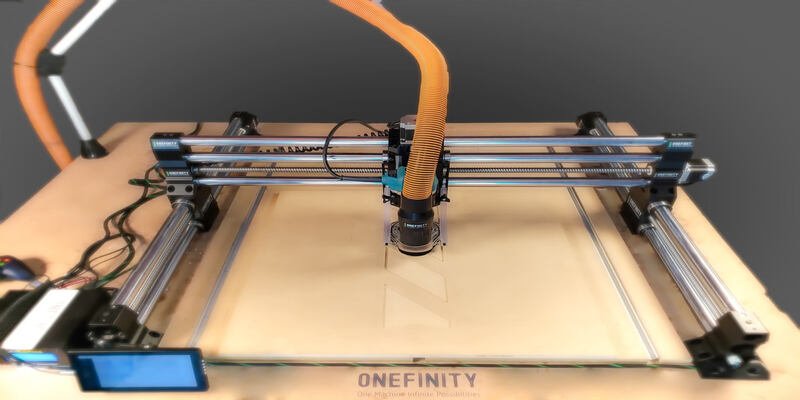

The Onefinity CNC is a relatively new range of machines that’s quickly gained the attention of hobbyists and CNC enthusiasts – so you might not be 100% familiar with its strengths and weaknesses.

Honestly, I hadn’t heard much about the Onefinity until I tested it, either.

But I was impressed. It proved itself to be an excellent value pick with a sturdy design, easy assembly that stacks up against popular CNC choices like the X-Carve and Shapeoko.

Although you need to provide your own router and workbed, this highly customizable machine can offer a great balance of simplicity and performance when configured correctly.

In this Onefinity CNC laser review, I’ll scrutinize everything from size and working area, to software, upgradability, and customer support, to help you work out whether this machine might be right for you.

Review Summary

THE REVIEW

Onefinity CNC

With more and more machines popping up as brands seek to capitalize on the ever-growing hobbyist CNC market, there’s more pressure than ever before for new routers to add something unique and top-quality capabilities to stand out from the crowd.

My Onefinity CNC review found that this machine certainly does enough to earn its place amongst the top hobbyist models.

The same machine is available in four different sizes for tackling different applications, but all have a really impressive build and offer great stability.

You can accurately cut a wide variety of materials including metals, the electronics are powerful, and there’s a decent range of upgrades you can make to your Onefinity.

There are a few downsides, such as the need to buy a router and a wasteboard separately, but these are relatively minor, and the kit you get when you buy a Onefinity CNC is undoubtedly impressive.

If you want to learn more about this exciting CNC machine, keep reading. I’ll explain each aspect of the Onefinity CNC in detail and then finish by covering how it compares to some other popular hobbyist routers.

CNCSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

Size & Working Area

One of the more unique aspects of the Onefinity CNC machine is that it’s available in four different sizes.

Here’s a quick rundown:

- X-35 Machinist – 16”x16”

- X-35 Woodworker – 32”x32”

- X-50 Woodworker – 32”x32”

- X-50 Journeyman – 48”x32”

The four Onefinity CNCs cost the following amounts (for just the base machine kit):

- X-35 Machinist – $1,453

- X-35 Woodworker – $2,042

- X-50 Woodworker – $2,541

- X-50 Machinist – $3,068

These are all reasonable prices, especially for the larger models, that are within the range of similar quality hobbyist routers.

So, on the one hand, you can get a small hobbyist machine that can easily fit on a benchtop in your home workshop, while at the other end of the scale there are larger machines for more demanding production and bigger projects.

Build & Stability

While there are differences between the various Onefinity CNC models, one thing that is true about all of them is their impressive build that offers fantastic stability.

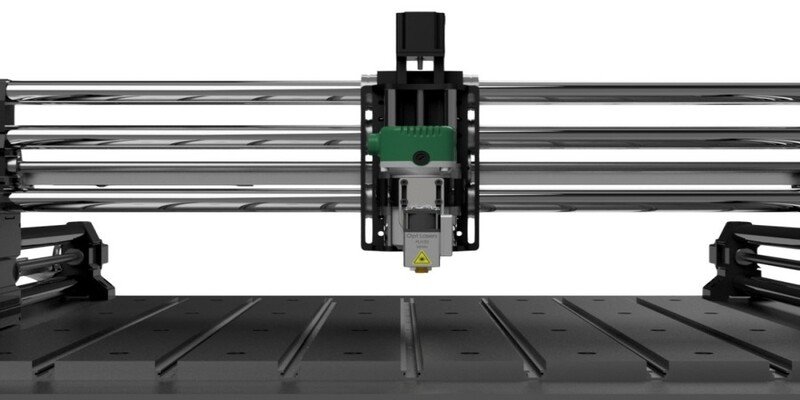

This is largely due to the all-metal construction, with the frame made of cylindrical hollow steel shafts, rather than aluminum extrusions as seen in many other hobbyist CNCs, such as Inventables’ X Carve and the Shapeoko 4 from Carbide 3D.

Steel is considerably stronger than aluminum, which means Onefinity CNC machines are very sturdy, rigid, and durable.

This makes them ideal for demanding CNC work that other hobbyist machines with less impressive builds wouldn’t be able to handle as well, such as metal cutting.

The size of the shafts varies depending on the model you go for, with the larger models being heavier and therefore more sturdy.

On top of the hardened steel shafts offering great stability, the fact that they’re hollow ensures that flexing is kept to a minimum while your machine is in operation.

They also remove the need for plastic wheels that require regular readjustment, making the machine more precise and easier to use than others.

However, one thing that may put some people off the Onefinity CNC is the models come without a workbed, so you need to source your own, either by buying one from the Onefinity site or making one.

In contrast, other popular CNC routers like the X Carve come with a workbed included, making set up quicker and easier and keeping the cost down. Onefinity does provide a manual for making your own wasteboard, though.

Router & Spindle

Another downside of the Onefinity CNC machines is that they don’t actually come with a router – you need to buy one separately.

This isn’t uncommon; other popular CNC machines like New Wave CNC’s Shark HD520 and the Shapeoko 4 also require you to buy routers separately, but on the other hand, the likes of the Sainsmart Genmitsu 4030 PROVer XL come with one included.

The Onefinity CNC is designed to work with the Makita 1-1.25 HP RT0701C router, which you can pick up from Amazon for around $200.

On the plus side, this is a seriously high-quality router – the 4.8-star rating from over 4,000 Amazon reviews is proof of that.

This router has a variable speed control dial that allows you to alter the speed from 10,000 to 30,000 RPM, so you can easily adjust it to suit your application, such as using a higher RPM to more effectively cut aluminum with your Onefinity CNC.

The electronic speed control ensures the speed remains constant under load, the smooth rack and pinion fine depth adjustment system makes for higher precision settings, and the quick release cam lock mechanism makes for simple depth adjustments.

Compatible Materials

Size isn’t the only difference between the different models of the Onefinity CNC – the various machines are also best suited to cutting different materials.

For example, the X-35 Machinist is ideal for cutting soft metals like aluminum and brass due to its compact size matching the smaller stock sizes generally used in metal cutting.

Of course, as the name suggests, the two Onefinity woodworker models are designed first and foremost for cutting wood.

This is due to the larger sizes of these models being best suited to common woodworking projects like making signs, advertisements, and furniture. However, with these Onefinity CNC models, you can still cut other materials like plastics, foam, soft metals, and more.

Then there’s the largest model, the X-50 Journeyman.

The huge working area of this router makes it ideal for cutting full sheets of plywood and MDF, but it can also still cut the other soft materials as the other models.

That’s where the name comes from – the Journeyman is a one-size-fits-all machine, whereas the others have more specific uses.

One of the most common questions I see asked about hobbyist routers is their suitability for cutting metals.

One of the best things about the Onefinity CNC machines is they’re all very effective at cutting aluminum and other soft metals – this video is just one of many on YouTube showcasing this fact.

Some users have even stated that the Onefinity is effective at cutting thin steel when using the right settings.

Axis Motion

The Onefinity CNC machine uses fast travel precision ball screws on hardened steel linear rails to move each of the three axes.

Ball screw mechanisms are preferred to the belt-driven mechanism used in many cheaper CNC machines due to them offering more precision and stability.

Onefinity also claims its ball screws require less maintenance than the lead screws used on other similar price machines. However, they do still require some lubrication in order to allow the machine to operate smoothly.

Another benefit of the Onefinity’s ball screws over lead screws is that they do not result in backlash, which is the main limitation of lead screw mechanisms. This means the machine is capable of more accurate cutting.

Control & Electronics

One thing that attracts many people to the Onefinity is that it uses a high-quality Buildbotics controller.

It’s considerably more powerful than the controllers used in some other popular hobbyist routers, such as the GRBL board used in Carbide’s popular Shapeoko series. The controller costs extra to add to your purchase, but it’s definitely something I’d recommend.

The Buildbotics controller is based on a Raspberry Pi board, so it’s a mini-computer within itself and doesn’t require hooking up to an external PC to run and control the machine.

It offers many more g code commands than the more basic GRBL boards, so it opens up a whole world of possibilities in terms of what you can do with your Onefinity, such as 4 axis control.

When ordering a Onefinity CNC, the manufacturer gives you the option to add an 8” touchscreen display for an extra $107.

Not only does this provide a nice, clear display for operating and monitoring your work, but it also means you can operate your machine offline without needing a computer (aside from the Raspberry Pi controller).

Onefinity even offers Xbox controller-styled “joypads” (both a wired and wireless version) for a seriously ergonomic way to control your Onefinity.

Many users have said this makes controlling the machine incredibly easy and fun.

In terms of the other electronics, this CNC machine uses Nema 23 stepper motors to move the axis, which is the same in many other hobbyist routers.

There are two motors used on the Y axis to help prevent racking and improve precision.

The Onefinity CNC machines offer microstepping up to 256 and perform 250k steps per second on each motor, allowing them to perform intricate movements with high speed, fantastic control, and accuracy.

To give you an idea of what that translates to in practical terms, one reviewer conducting a comparison of the Onefinity and the highly popular X Carve found that the Onefinity can cut wood almost three times as fast as the X Carve.

Software

The Onefinity CNC comes with a CAM and control software that’s preprogrammed onto the Buildbotics controller, but it doesn’t come with any CAD software.

While there are other hobbyist machines that come with CAD packages included, such as the X Carve and Shark HD520, I don’t think this is necessarily a major limitation, as experienced hobbyists will often prefer to use their own software of choice anyway.

You can use any CAD software for creating your designs and then converting them into g code to send to the Onefinity.

I recommend checking out our guide to the best CNC software if you’re unsure of which program to use. Onefinity does offer licenses for some popular programs, like Carveco Maker and V-Carve, through its website.

The control software that comes included on the Buildbotics controller is a relatively stripped-back, simple program that has a user-friendly interface.

It accepts standard g code from any CAM software and you can access it via a web browser using any device that’s on the same network as the control board.

Alternatively, you can connect via ethernet cable to the control board and use the software that way.

Upgradability

Upgradeability is one of the main factors on which I judge CNC machines, as it’s important to have the option to improve your router and expand your working possibilities.

So, I was glad to see that the Onefinity offers an upgradeability of a similar level to other top CNC routers I’ve reviewed.

One of the highlights – and most popular upgrades among users – is the 7W laser module.

This is built for the Onefinity by JTech Photonics, a brand that provides laser modules for other popular routers like the BobsCNC Evo 4.

It’s fairly costly at over $700, but it’s a really high-quality module that’s ideal if you want to achieve precise engraving of aluminum, plastics, and other materials with your Onefinity.

While the laser module is a more application-specific upgrade, one I would recommend all users make is adding the Infinite Dust Collection Kit.

It’s a really high-quality dust collector that uses Onefinity’s own Suck It Pro dust boot, so it makes for much cleaner and safer cutting.

Another recommended upgrade is the Onefinity touch probe, as it makes it much quicker and easier to zero the three axes.

Plus, it probes from the top right corner instead of the bottom left like on some other machines, which helps maximize the cutting area and prevent the cutter from being damaged in the event of your connection being interrupted.

In addition to these upgrades, you can buy a wide variety of accessories for your Onefinity CNC via the brand’s website. These include router bits, an 80mm spindle mount, clamps, nuts, and cables.

Another interesting accessory is the Onefinity wall mount system.

This is compatible with all the Onefinity CNC models and allows you to mount your machine vertically on a wall, so you can save a lot of space, which is particularly useful if you’re interested in one of the larger models.

Assembly

Overall, it’s pretty simple to put the Onefinity CNC machine together thanks to the modular design.

All the parts come preassembled, so all you need to do is follow the detailed assembly manual that comes with your kit to get up and running. Plus, all the electronics are plug and play, so there’s no complex wiring or installations to deal with.

Overall, in most cases, it’ll probably take an hour or so to get the machine set up and calibrated.

The one downside, as mentioned earlier, is that you’ll need to source your own workbed and attach it to your kit before you can start using the Onefinity CNC.

If you need some extra help putting your Onefinity CNC together, there’s a detailed build tutorial on the brand’s YouTube channel.

Customer Support

I always check the customer support and community aspect when reviewing CNC machines, and I was impressed by the level of service offered by Infinity.

The brand, which is owned by Kirbre Enterprises Inc, is based in Ontario, Canada, and offers several support channels.

You can send general inquiries to [email protected] and get tech support by emailing [email protected].

The brand also offers phone support on 1-888-717-4242, with lines open 9am-3pm ET Monday through to Friday. However, you can’t get technical support over the phone.

Onefinity also offers a variety of helpful resources you access through the support page, including a user manual, FAQs, a controller software manual, and other guides. There are also helpful and interesting videos on the Onefinity YouTube channel.

Another positive about Onefinity CNC is that there is an active community around it despite the brand being relatively young, which indicates how popular the machines are among hobbyists.

There’s the community forum as well as a Facebook group with over 14,000 members.

The Verdict

Overall, I was very impressed with the Onefinity CNC machines. Almost every aspect of them is positive, from the fantastically stable steel frame to the high-quality ball screws and high load linear bearings.

These features make the Onefinity suitable for cutting a wide variety of materials with great precision, from woods and plastics to soft metals like aluminum.

I’m also a really big fan of the powerful electronics at the heart of the Onefinity CNC, particularly the Buildbotics controller, which is an upgrade on the more basic GRBL boards seen in many other affordable CNC machines.

Of course, there’s also the ability to purchase the machine in four different sizes, so whether you’re looking for a compact metal cutting machine, a quality woodworking router, or if you want to cut full sheets of plywood and MDF, there’s a Onefinity CNC for you.

There are a few minor limitations, such as needing to purchase a Makita router, wasteboard, and dust boot separately, which do make the entire operation rather costly.

However, you’re certainly paying for good quality.

Like the sound of the Onefinity CNC? You can purchase one for yourself today through the Onefinity website.

Alternatives

The Onefinity CNC machines are certainly impressive, but that doesn’t mean they’ll suit everyone. Here are some top alternatives.

Inventables X Carve

- Price: $2,047 — Available here

The Inventables X Carve is a widely used CNC machine that’s gained popularity thanks in part due to its incredibly user-friendly design and the excellent customer support offered by Inventables.

It’s great for beginners as it comes in a full kit with everything you need, including a spindle, as well as an Easel software package, things that you don’t get with the Onefinity CNC. So it’s really quick and easy to get going with the X Carve, and it’s a very sturdy and precise machine to boot.

Carbide Shapeoko 4

- Price: $2,300 — Available here

The Carbide 3D Shapeoko 4 is a highly popular CNC router among hobbyists and is a very reliable machine to consider if you’re still looking for an alternative after reading this Onefinity CNC laser review.

It comes in three different sizes and is made of quality components that mean the end result is a really stable, precise cutter at an affordable price. Carbide also offers the Nomad 3, a really impressive benchtop CNC mill that’s ideal for cutting metals, including strong metals like steel.

Onefinity CNC Specs

- Size: from 16”x16” to 48”x32”

- Frame material: steel

- Router: not included, Makita 1-1.25 HP RT0701C recommended

- Axis motion: ball screw

- Motors: stepper

- Supported OS: Windows, Mac, Linux

- Control: Raspberry Pi, Online & offline

- Software: not included

- Connectivity: Ethernet

FAQs

Is Onefinity CNC good?

The Onefinity CNC machines are certainly some of the highest quality hobbyist routers out there.

They are good enough to rival the most popular hobbyist CNC machines, such as the Shapeoko 4 and X Carve.

What router works with Onefinity CNC?

The Onefinity CNC is designed to work with the Makita 1-1.25 HP RT0701C router. This is a high-quality variable CNC router with an RPM range of 10,000-30,000.

Where are Onefinity CNC made?

Onefinity CNC machines are made in and shipped from Toronto, Canada.

How do I connect my computer to CNC Onefinity?

As the Onefinity CNC uses a Buildbotics controller based on a Raspberry Pi board, you don’t need to connect your computer to the machine in order to use it.

If you do want to control the machine via your PC, you can do so through an ethernet cable.

How can I transfer files between computer and controller without an ethernet or WiFi connection on Onefinity CNC?

If your computer doesn’t have an ethernet port and if you don’t have a WiFi connection to connect to your Onefinity CNC, the best option is to use a USB to ethernet adapter.

Other articles you may be interested in:

- The Maslow CNC review

- The best CNC routers for small businesses

- The best DIY laser cutters & engravers

- The best plasma cutters

- X Carve vs Shapeoko 4 CNC comparison

- Inventables X Carve alternatives