With the right plasma cutter you can make cleaner cuts, reduce costs, minimize noise and mess, and even cut metal in a safer way.

In this guide, I’ll compare my hands-on experience with a wide range of the best plasma cutters to help you find something to fit your needs, experience level – and budget!

For most users, I’d recommend the Tammible Plasma Cut50. This user-friendly and affordable plasma cutter can tackle the vast majority of projects hobbyists and small businesses will require – making it excellent value for money.

If you’re willing to spend a little more, the Lotos LTP5000D is similarly impressive and super portable, while the Hobart AirForce 12ci is a more durable and heavy-duty pick.

| Plasma Cutter | Price | Available at |

|---|---|---|

| Tammible Plasma Cut50 | $275 | Amazon here |

| Lotos LTP5000D | $430 | Amazon here |

| Hobart AirForce 12ci | $879 | Amazon here |

| Hypertherm Powermax30 XP | $1,680 | Amazon here |

| Miller Spectrum 625 X-Treme | $2,005 | Amazon here |

| Hypertherm Powermax 125 Combi | $12,250 |

The Best Plasma Cutters – Ranked

1. Tammible Plasma Cut50 – Best Cheap Plasma Cutter

- Price: Check price at Amazon here

- Weight: 25lbs

- Size: 396 x 155 x 250 mm

Pros

A good budget plasma cutter.

User-friendly that’s quick to set up and easy to use.

Reliable and durable.

Cons

The cuts will be slightly rougher the deeper you cut.

The Tammible Plasma Cut50 is our pick for the best budget plasma cutter. This machine is perfect for beginners working on a budget as while it’s very cheap, it’s still a quality plasma cutter that can be used for a wide range of projects, including metal processing, automotive work, ducting work, repair, maintenance and more.

It’s also a very user-friendly plasma cutter that’s quick to set up and easy to operate, with a smooth cutting surface to reduce slag and provide a longer life for consumables.

It cuts smoothly up to 1/2”, and you can cut deeper, although the cut will be slightly rougher. The Tammible Cut50 can be used to cut carbon steel, stainless steel, copper, iron, alloy, aluminum and other mild metals.

Another benefit of this plasma cutter is its solid construction; while it’s one of the cheaper models, it’s still very reliable and durable. It’s a good, low-cost option for small businesses and professionals as well as hobbyists.

With a quality plasma cutter like the Cut50, hobbyists can work on a wide range of projects at home. Many hobbysits use them to create plasma cutter art and designs, and signs that you can hang around the house or yard.

You can also use work on more functional projects, like gates and fireplace screens. You can even use them for DIY car repair projects if you have the expertise.

The Cut50 has built-in over-heat protection and over-voltage protection, as well as good insulation and strong heat dissipation, so it’s a safe and secure machine to use.

It also has a digital LCD display, so you can easily read the front panel air pressure gauge. You can adjust the cutting current to meet the demands of your project, and the impressive manufacturing means the Cut50 makes little noise when you use it.

2. Lotos LTP5000D – Best Under $500

- Price: Check price at Amazon here

- Weight: 26lbs

- Size: 381 x 152.4 x 304.8 mm

Pros

One of the best when it comes to value for money.

Fantastic for beginners.

Cons

The deep cuts will be slow and rough.

If you’re looking to buy a decent plasma cutter on a budget, you can’t go wrong with the Lotus LTP5000D.

This is one of the best 110v/220v plasma cutters we’ve come across when it comes to value for money. For starters, this machine boasts a 10- to 50-amp cutting range and a non-touch pilot arc that provides clean, efficient cuts on metal up to 12” thick, even if it’s rusty or painted.

The pilot arc technology means you can cut without touching the tip to the metal, making for higher quality cutting and a longer lifespan. You can also cut thicker metal, although the cut will be slower and rougher.

This plasma cutter also boasts impressive drag technology ideal for drawing lines, as well as a standoff that keeps the nozzle clean and makes it easy to start the plasma slice and cleanly cut all the way through.

The LTP5000D is also a fantastic choice for beginners as it’s incredibly easy to set up. You can get started in under a minute, as the pre-installed NPT 1/4” industry type D plug and air filter regulator allows you to quickly connect to your air compressor. It also weighs just 26 pounds, so it’s easily portable.

While its cutting power and material quality aren’t best suited to demanding workshop environments, the Lotos LTP5000D is perfect for hobbyists needing to cut 1/2” plates and less.

3. Hobart AirForce 12ci – Best Plasma Cutter with Built-In Compressor

- Price: Check price at Amazon here

- Weight: 31lbs

- Size: 420 x 470 x 286 mm

Pros

Lightweight and high-quality.

Has some really impressive features.

Cons

Some users have complained about low pressure.

Hobart is a well known maker of high-quality plasma cutters, and the AirForce 12ci is one of their flagship models.

This is a lightweight, portable plasma cutting machine that offers professional-grade quality. It’s best suited to serious home workshop hobbyists and professionals who need an easily portable plasma cutter for repair jobs, weighing just 26 pounds . It has an internal piston-driven air compressor for high system portability.

The AirForce 12ci has some really impressive features that make it a popular choice among plasma cutters. For example, the XT12R torch has an ergonomic safety trigger and economical cutting tips, making it a comfortable and efficient machine to use safely.

It also has a fan-on-demand system so the fan only runs when needed to reduce the dust and debris that’s pulled into your machine. On top of that, there’s thermal overload protection and a postflow cooling circuit to help the plasma cutter perform and last longer.

It’s also worth mentioning the pilot arc start that ensures you a consistent arc with each cut and reduces tip burnout. Finally, the plasma cutter has diagnostic lights that let you know when it indicates power, temperature and torch readiness to help minimize downtime.

The only real downside to this plasma cutter is that some users have complained of low pressure, although overall we think it’s a great machine for the price.

4. Hypertherm Powermax30 XP – Best Value For Money

- Price: Check price at Amazon here

- Weight: 21lbs

- Size: 355 x 140 x 292 mm

Pros

Small, cheap, and easy to use.

Offers more than enough features to carry out most small-scale projects.

Versatile.

Cons

It doesn’t have the same engraving capabilities as some other plasma cutters.

The Hypertherm Powermax30 XP is a small, cheap, and easy-to-use plasma cutter that’s great for serious hobbyists and professionals. This machine offers more than enough features to carry out most small-scale projects.

The Powermax30 is notable for its versatility, with a unique “two in design” that provides enough power to cut thick metals while also having a range of consumables that are included in the kit for more detailed, thin metal cutting. The various consumables leave a clean edge and narrow kerf when cutting thin metals.

While it doesn’t have the same engraving capabilities as some other plasma cutters, you can finish jobs efficiently without the need for secondary operations thanks to its fast cutting speeds and high cut quality.

The plasma cutter has a 30-amp system that uses air or nitrogen to cut metals like aluminum and stainless steel. Overall, the Powermax 30 is ideal for drag cutting, extended reach cutting, extended reach gouging, and fine feature cutting.

The Powermax30 is ideal if you’re looking for a portable plasma cutter, due to its small size, light weight and easy set up. You can plug it into any 120V or 240V power vaults and it comes with plug adapters. It’s also built for heavy-duty use and can be used in industrial environments.

5. Miller Spectrum 625 X-Treme – Best Pilot Arc Plasma Compressor

- Price: Check price at Amazon here

- Weight: 21lbs

- Size: 336 x 140 x 228 mm

Pros

Has some fantastic features.

Perfect for professionals across a range of industries.

Cons

No major drawbacks.

Developed by Miller, the Spectrum 625 X-Treme is a very high quality plasma cutter with some really fantastic features.

One of the most notable aspects of this machine is the 7/8” rated cutting capacity. The torch travels approximately 15 inches per minute, achieving an incredibly steady and precise cut. This rating is more than enough for most projects.

The machine uses a XT40 torch, which boasts an ergonomic handle with an innovative no-slip grip as well as a thumb guide and finger contours to help reduce operator fatigue. It also features a flexible cable for easy maneuvering and a flexible “Quick Connect” work lead with a heavy duty clamp.

Another impressive feature is the Spectrum 625 X-Treme’s Auto-Refire technology. This automatically controls the pilot arc when cutting expanded metal or multiple pieces. The pilot switches in and out as fast as needed, so there’s no need for manual re-triggering, making for a more convenient working process.

This plasma cutter also has automatic air regulation, so it automatically compensates for input pressure variation. This helps maintain constant recommended torch pressure, improving cutting and gouging quality.

The 625 X-Treme is perfect for professionals across a range of industries, and weighing under 23lb, it’s easily portable. As an added bonus, it comes with a shoulder strap and a protective case you can transport it.

Another convenient feature of this machine is the Wind Tunnel Technology and Fan-On-Demand. The Wind Tunnel Technology is an internal air flow that protects electrical components for improved reliability, while the fan cooling system operates only when necessary to help reduce dust and dirt being pulled into the cutter.

6. Hypertherm Powermax 125 Combi – Best CNC Plasma Cutter For Industrial Use

- Price: $12,274

- Weight: 105lbs

- Size: 592 x 274 x 508 mm

Pros

Professional-grade.

Can also be used for drag cutting, fine feature cutting, max control gouging, and mechanized cutting.

Great durability.

Cons

Doesn’t come cheap.

It certainly doesn’t come cheap, but Hypertherm’s Powermax 125 is a fantastically durable and versatile machine that offers extremely high quality in industrial settings.

As you’d expect from a professional-grade plasma cutter, the Powermax 125 has a wide variety of applications. For example, you can use it for flush cutting for cutting close to base materials at a 45 degree angle, and it’s also suitable for max removal gouging so you can aggressively remove metal and carry out extreme metal washing.

This plasma cutter can also be used for drag cutting, fine feature cutting, max control gouging, and mechanized cutting. It offers handheld cutting up to 38mm and mechanized piercing up to 25mm.

Hypertherm has specifically optimized this cutter for efficiency, and you can cut 5 times faster than oxyfuel on 12mm mild steel. It also has a 100% duty cycle to help you maximize your cutting time, while the excellent cut quality reduces grinding and edge preparation time.

Another key advantage is its durability. It has up to four times longer consumables life than other cutters in the same amp range, saving you money and time, and the electrode end-of-life detection protects the torch and workpiece by automatically stopping if the electrode becomes overused.

Other features that make this cutter really stand out include the SmartSense technology that ensures the air pressure is always correctly set, and the SpringStart function that ensures consistent starting and torch reliability.

It uses Duramax and Hymamp torches that are designed for high impact and heat resistance, making this cutter effective in even the harshest conditions.

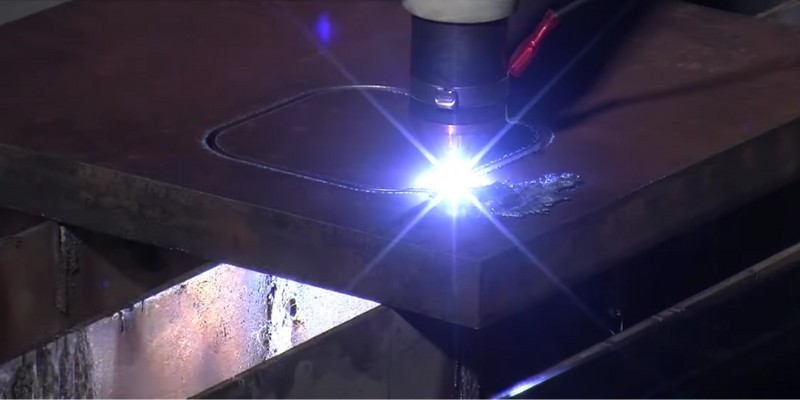

What are Plasma Cutters?

Plasma cutters are machines that use ionized gas torches to cut through conductive materials such as metals. They are mostly used to cut steel, stainless steel, copper, aluminum and brass, although they can be used on a wide range of other materials.

Plasma cutting first emerged in the 1960s when it proved to be a more effective way of cutting metals than traditional metal-on-metal cutting. It is safer, more accurate and less messy.

It also produces cleaner edges than oxyfuel cutting, a technique that uses a combination of fuel gasses and oxygen.

| Plasma Cutting | Traditional Cutting | Oxyfuel Cutting | |

|---|---|---|---|

| Material Compatibility | Steel, stainless steel, aluminum, copper, brass, cast iron | Steel, cast iron, aluminum | Steel, cast iron |

| Cutting Quality | Produces a high-quality cut with minimal kerf and distortion. | May produce rough or jagged edges with a wider kerf and distortion. | May produce rough or jagged edges with a wider kerf and distortion. |

| Equipment Needed | Requires a power source, compressed air, and a plasma torch. | Requires a saw or grinder, and may require additional tools for finishing. | Requires a fuel gas, oxygen, and a torch. |

| Capability for Intricate Shapes | Yes | Limited | Limited |

While early plasma cutters were large and slow, technological advances have made many small, lightweight machines available, opening plasma cutting up to hobbyists.

With the development of inverter technology, recent years have seen more and more plasma cutters become available across lower price ranges – making them accessible to the masses!

Plasma cutting is also commonly used in large-scale CNC applications and across industries such as automotive repair, construction and in fabrication.

Using a plasma cutter is relatively simple and beginners can get to grips with it fairly quickly.

Once you’ve set up your cutter and connected it to an air compressor and a power supply, you just need to attach the torch to the cutter, select your cutting amperage and get to work.

Some of the best plasma cutters even have built-in air compressors to make the process simpler.

If you enjoyed this ranking of the best plasma cutters, you may also enjoy:

- The best CNC machines buyer’s guide

- The best 4×8 CNC routers

- Our buyer’s guide for the best laser cutters and engravers