This is my review of the Maslow CNC, a CNC machine from MakerMade that’s unique for offering a huge cutting area at a discount price.

Finding the right CNC machine can be tricky, especially if you’re a beginner. After all, if you’re forking out hundreds or thousands on a machine, you need to be confident in what you’re buying.

As an expert in CNC, I’m using my knowledge and experience with mills and routers to create in-depth reviews, so you can get a good idea of what to expect from different machines.

This Maslow CNC review looks into how effective it is as a 4×8 router, what you can cut and its pros and cons for the price, as well as circumstances where you’d consider alternatives.

CNCSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

Review Summary

Pros

Large 4ft by 8ft cutting area

Extremely low price

Wall-mounted

Great support and active community

Upgrade kit available

Cons

Have to buy router separately

Lengthy assembly

The Maslow CNC is certainly one of the more unique CNC machines I’ve reviewed.

It’s the result of an open-source, community-driven project that aimed to make large format CNC work more affordable and available than ever before.

It certainly achieves that aim, offering a very large 4ft by 8ft working area at a really cheap price of around $599.

The machine is also wall-mounted, meaning it can fit in many hobbyist workshops that wouldn’t otherwise be suited to such a large machine. I also really like the active community that surrounds the Maslow.

There are some limitations, though.

For example, you’ll need to source or buy a frame for the machine yourself, and you’ll also need to buy a router and spindle separately. This means the Maslow won’t be for everyone, but if you want a large working area at the cheapest price, then it’s a great choice.

Want to find out before about the Maslow CNC? This review covers everything you need to know to make an informed decision. Let’s get into it.

Size & Working Area

The huge working area is undoubtedly the most unique aspect, and the biggest selling point, of the Maslow CNC.

With this machine, you get an incredible 4ft x 8ft working area, so you have plenty of room to work on large-scale projects.

As you can see on the Maslow CNC website, the possibilities are endless – from tables and cabinets to wine racks and even cat houses, the large cutting area is great for a wide variety of different projects.

It isn’t the working area on its own that makes the Maslow unique, though, as there are many other routers of this size.

What really makes it stand out is the incredibly low price, which is a fraction of what you have to pay for virtually any other 4×8 CNC router.

Another interesting aspect, and one which shows this is very much a hobbyist machine, is that the router is wall mounted. This means you get a 4×8 working area without having to need a huge amount of floor space, so it’s ideal for smaller home workshops.

Build & Stability

When you buy the Maslow, you don’t actually get the frame, so you have to build one yourself using the assembly instructions.

What you do get is the electronics, mechanical components like the axes, and mounts.

As this is a wall-mounted router, it looks pretty different from your standard desktop or tabletop CNC machine. You don’t actually mount it on your wall, though, but rather attach it to the frame at a slight angle which you can then place against your wall.

So, when you machine pieces using the Maslow, you do so from an upright angle, rather than laying the material flat. This brings its various quirks, which we examine in the sections below, so make sure to keep reading if you want to learn about this aspect of the Maslow.

Router & Spindle

One downside of the Maslow CNC is that, unlike the majority of CNC machines, it doesn’t actually come with a router or spindle. So, you need to buy one separately, and you need to make sure it’s a fixed-based router with a Z axis plunge.

MakerMade suggests using a Bosch POF 1200, but the choice is yours.

Some users have noted that as the Bosch POF 1200 is quite large, it’s recommended to make a mount for the router when you’re not using it to avoid bumping into it.

Makita and Dewalt routers are examples of ones that have lower profiles than the Bosch.

It’s not just as simple as plugging the router in and starting to cut, though.

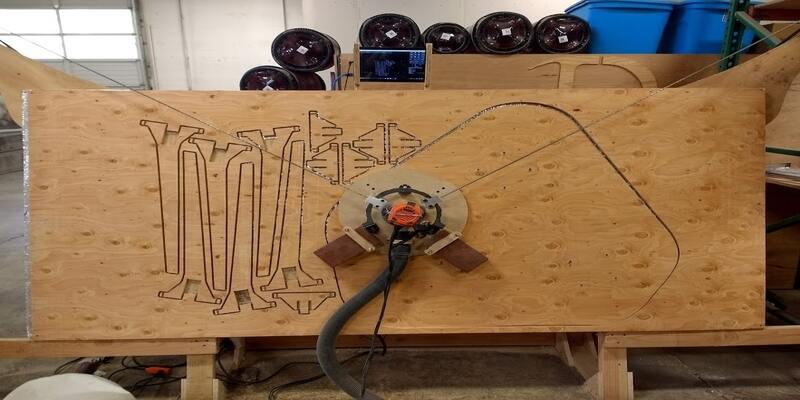

Due to the unique upright build of the Maslow, you need to attach the router to a component known as the “sled”. The sled is essentially a plywood base with a circular metal ring attached that’s used to hold the router.

You get the metal part in the Maslow kit, but you’ll need to source or build your own base using the instructions.

The sled also needs to have two mounts attached for holding items weighing 8-10lb, such as bricks or free weights, in order to help it move across the cutting area smoothly.

Compatible Materials

The Maslow CNC is best suited to woodworking, so it’s ideal for machining materials like hardwood, softwood, plywood, and MDF.

You can also use it to cut a variety of other soft materials, including plastics and composites.

You can cut at speeds of up to 40 inches per minute (ipm).

It’s worth bearing in mind that this is pretty slow compared to many other hobbyist routers, but it’s one of the sacrifices the Maslow makes in order to keep the price so low.

However, it’s actually an upgrade on older versions of the Maslow which maxed out at around 30ipm (MakerMade has continued to make some upgrades to the Maslow since it first become available).

And now to one of the main questions people have about hobbyist CNC routers – can it cut aluminum?

In the case of the Maslow CNC, the answer is that it’s possible, but this is far from an ideal aluminum cutting machine.

You’ll need to find the right conditions, but even then the Maslow will still be slow at cutting metals. For example, this user cut 0.040” sheet aluminum with a 1/4” flute bit at 15ipm and 12,000 RPM.

Axis Motion

The way the axes work is one of the most interesting aspects of the Maslow CNC.

In this machine, the sled that holds the router is driven by a drive chain system that’s in turn driven by motors. This chain system determines the X and Y axis movement.

The chains move along sprocket wheels – one in each of the top corners – with the slack and pull on each side determining the position of the sled. This means it’s vital to keep the chains tense in order to cut effectively.

The innovative design also uses gravity to its advantage in order to achieve accurate upright cutting.

The kit comes with an 11” chain that’s designed for the standard frame size, but if you want to use a larger frame there’s the option to purchase a 15” chain.

The Z axis, on the other hand, is driven by a stepper motor.

One thing I really like about the Z axis is that it automatically adjusts cutting depths so you don’t have to do it manually. The travel of the Z axis will depend on the router and tools you’re using.

Control & Electronics

This CNC machine is controlled by an Arduino Mega 2560 board with a shield made by MakerMade that drives the DC motors on each axis.

The board uses Holey v51.28 firmware, which is developed specifically for the Maslow CNC. You need to use a USB-B cable in order to connect the board to your PC. There’s no offline control option for the Maslow.

The closed-loop geared DC motors are what drive the chain system which moves the sled across the workpiece.

These motors are low torque, but the kit comes with a gearbox you can use to increase the torque.

The electronics of the Maslow are relatively basic, which isn’t a surprise considering the price. They offer enough power for a wide variety of hobbyist projects, but not for intensive machining.

Software

Due to the unique nature of its machines, Maslow has developed its own CNC software called Makerverse, which is open source and completely free to used.

It’s a modification of the CNCjs software, which is based on GRBL.

This is a browser-based program but it can be used offline if you install it on your computer, and it’s available on Windows, macOS, and Linux.

What I really like about Makerverse is that it’s very beginner-friendly and therefore suited to the Maslow’s target audience, which is the casual hobbyist. It also has nice tools like the ability to automatically calibrate the router to help ease you into things.

Bear in mind that Makerverse can only be used to send g code to your Maslow and operate it (it also has jogging keys for this purpose).

You’ll still need to use a different software for creating your designs and converting them to g code – read our best CAD/CAM software guide to check out our favorites.

You do, however, get a USB with 10 free projects to get you started when you buy a Maslow kit, which is a nice touch.

Upgradability

There are several possible upgrades you can make to the Maslow CNC, but by far the most significant is upgrading it to an M2.

The M2 is a standalone machine you can buy from MakerMade, and it’s the direct upgrade to the Maslow, but the manufacturer also provides a Maslow-to-M2 upgrade kit that you can do yourself.

The upgrade kit costs around $610, so it’s a bit more expensive than the actual Maslow.

Now, if you can afford $1,198, we recommend just buying the M2 outright – you can learn more about this machine by reading our MakerMade M2 review.

However, if you’re on a tighter budget, it’s really nice to have the option to buy the significantly cheaper Maslow and then be able to upgrade it further down the line if you wish.

It’s also possible to make other upgrades to the Maslow, such as adding a laser module. However, if you intend to make this kind of addition, I’d strongly recommend just going for the M2.

Assembly

One downside to the MakerMaade Maslow CNC is that it isn’t the easiest machine to put together – this isn’t a preassembled CNC router kit that you can get started within 30 minutes.

Firstly, you’ll need to build a frame, which MakerMake provides instructions for.

You’re also going to need to build the sled once you’ve got a router, install the electronics, assemble the Z axis, and finally calibrate the machine.

The calibration part is particularly important, as if you get this wrong you won’t be able to achieve accurate results.

For most people, it’ll probably take at least a weekend to get the Maslow set up, and you need a fair few different tools in order to do so. There are many Maslow assembly videos on YouTube, so these can also be helpful.

Customer Support

One thing that can’t be denied about MakerMade is that it’s one of the better CNC brands when it comes to customer service.

After all, this is what you’d expect considering that it started out as an open-source community project, but it’s nice to see MakerMade has kept those values as it’s transitioned into a professional manufacturer.

If you need to get in touch, you can call MakerMade on 888-696-0913, email [email protected], complete a contact form, or call 888-696-0913.

You can also find answers to many common issues on the support page where you’ll find lots of resources, including FAQs and past discussions on issues.

However, while the above is pretty standard, MakerMade certainly goes above and beyond to serve its customers. This is shown by the weekly Q and A sessions with Patrick Kinnamon, CEO and founder of the company.

One of my favorite thing about MakerMade as a whole, though, is the online community that’s focused on its machines.

There’s a whole variety of different discussions on the forum page, where you can discuss all things Maslow CNC. MakerMade even offers a community marketplace where you can buy and sell projects made using its machines.

The Verdict

The Maslow CNC is one of the most interesting CNC machines I’ve reviewed, and its pretty distinct benefits and limitations mean it’s best suited to only certain hobbyists.

Of course, the big put-off for some people will be the lengthy and at times difficult assembly process, along with having to buy a router and other parts separately.

On the plus side, it’s the router that offers a 4ft by 8ft cutting area at the lowest price on the market, so if that’s what you’re after, then it can’t be beaten in that regard.

Want to try out the Maslow CNC for yourself? You can order one today through the MakerMade website.

Maslow CNC Alternatives

If the Maslow CNC isn’t quite doing it for you, or you want to check out some alternative options, these are a couple of my favorite hobbyist routers.

MakerMade M2

- Price: $1,198 — Available at MakerMade here / Amazon here

We’ve already touched on the MakerMade M2, which is the direct upgrade on the Maslow.

While it’s the same size as the original model, the M2 is a much higher quality machine and represents the move from a community project to a professional CNC manufacturer.

With the M2, you get all that’s good about the Maslow but with much better electronics, stronger components, and new features like a dust collection attachment.

Bear in mind, though, that you’ll still need to buy a router separately and construct a frame if you go for this machine.

BobsCNC Evolution 4

- Price: $1,230 — Available at Amazon here

The BobsCNC Evolution 4 is a great choice if you like the MakerMade machines but want to do without the lengthy assembly process and having to source a router separately.

This is a full CNC router kit, so all you need to do is put the parts together.

It’s made of wood like the Maslow in order to keep the cost down, but offers a really decent 2ft by 2ft working area and lots of stability – it can even machine soft metals under the right conditions.

You can read our BobsCNC Evo 4 review to learn more about this router.

Specs

- Engraving area: 4ft x 8ft

- Frame material: wood

- Max cutting speed: 40ipm

- Motors: stepper & geared

- Supported OS: Windows, Mac, Linux

- Control: Online

- Software: Makerverse

- Connectivity: USB-B

FAQs

Is the Maslow CNC worth it?

If you want a large 4ft x 8ft working area at a discount price, the Maslow is a great job.

However, needing to build a frame and buy a router separately means it’s not suited to all users.

What can you build with the Maslow CNC?

You can build all sorts of different projects with the Maslow CNC, but the large cutting area means it’s most commonly used to make furniture like tables and shelves.

How deep can the Maslow CNC cut?

As you need to source a router separately, there’s no set limit to how deep the Maslow CNC can cut – it depends on the router, spindle, and bits you’re using.

Other articles you may be interested in:

- Maslow CNC alternatives

- The best DIY CNC routers

- The best CNC routers for small businesses

- The best CNC mills

- The best 4×4 CNC routers