Key Takeaways

- What is CNC programming: CNC programming is creating instructions for a CNC machine using software to control how it moves and interacts with the material workpiece.

- How to learn CNC programming: The best way to learn CNC programming is to find a CNC shop that is hiring and start as a machine tool operator. You can also watch online tutorials and use CAD/CAM software to practice.

- What are the types of CNC programming software: CNC programming software includes CAD (computer-aided design), CAM (computer-aided manufacturing), simulation, post-processor, and control software. CAD and CAM are the most important and widely used.

- What are the benefits of CNC programming: CNC programming is a high-demand and rewarding career that can be applied to many industries. CNC programmers can create complex and precise parts from various materials using different machines.

I have been a professional CNC programmer in a shop for over 15 years, and in this article I’ll explain the basics of CNC programming, how you can learn CNC programming, and my tips for this. I’ll cover:

- What is CNC programming?

- Is CNC programming hard to learn?

- What does a CNC programmer do?

- Key Takeaways

- What is CNC Programming?

- How Does CNC Programming Work?

- What Language is Used for CNC Programming?

- What Does a CNC Programmer Do?

- The 3 Main Types of CNC Programming

- CNC Programming For Beginners – A Guide To Starting

- What Software Do CNC Programmers Use?

- Which Industries use CNC Programmers?

- CNC Programmer Career Outlook

- Examples of Software CNC Programmers Use

What is CNC Programming?

CNC programming (Computer Numerical Control programming) is creating instructions for a CNC machine using software to control how it moves and interacts with the material workpiece. These machines include CNC milling machines, CNC lathes, and 3D printers.

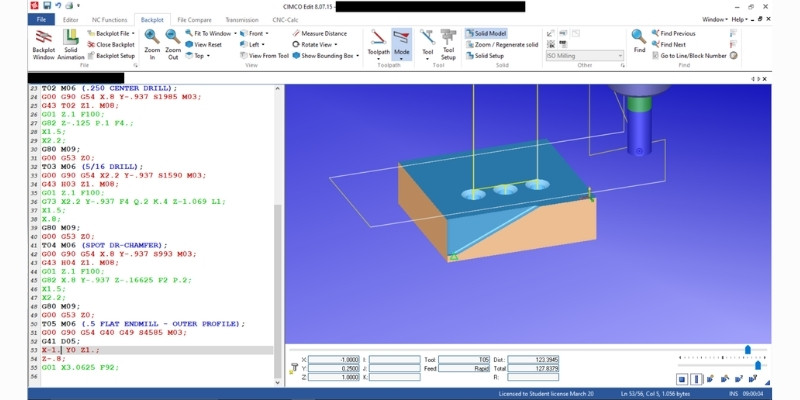

These CNC machines receive their instructions using a programming language called g-code. G-code is created by a programmer at the machine or through a CAM (Computer-Aided Manufacturing) program.

How Does CNC Programming Work?

CNC programming involves taking a 3D CAD model, and converting it into a CNC program with defined toolpaths (where the tool moves during the operation), and any other parameters for the operation.

These parameters include the speed, feed rate, which tools to use, and there are many others. The CAM software then takes these toolpath movement instructions, and parameters, and converts these into G-code, which the CNC machine interprets and operates based on.

What Language is Used for CNC Programming?

CNC programmers use G-code commands to instruct CNC machines what to do. They’re called g-code because most of the letters in the code start with G, but there are also M-codes, and some commands also start with F.

Here’s an example g-code I have written for a hypothetical drilling scenario, with what each code does to the machine. The animation below shows how the machine would respond to the following g-code.

- S700 – Set spindle speed to 700 RPM

- M03 – turn the spindle on

- G0 x100 y250 z5 – Move as fast as possible (g0) to coordinates (100,250,5) mm

- G0 z2 – Lower the tool quickly to z=2

- F100 – feed rate is 100 mm/min (speed to push the tool in the workpiece)

- M08 – Turn on coolant

- G1 z-10 – Slowly lower the tool 12mm, Move with feed rate speed (g1) until you reach z=-10mm

- M09 – Turn coolant off

- G0 z5 – retract the tool upwards to z=5mm

- G0 x0 y0 – Go back to the coordinates (0,0,5)mm

- M05 – Turn off the spindle

In practicality, you’ll never have to do this, as CAM software will automatically generate the g-code. But, it’s a useful example to show what goes on under the hood.

What Does a CNC Programmer Do?

A CNC programmer writes instructions that tell the CNC machine tell the machine to move in a certain direction, by a certain distance.

What a CNC programmer does also depends on how complex the part is that they need to make. The more complicated, and the tighter the tolerance required, means more time spent programming.

A professional CNC programmer could program a simple square part with a hole in it in under 3 minutes. But, I’ve also personally spent 3 days programming a 5-axis part that required a crane to get into the machine.

So what you’ll do as a CNC programmer depends on your skill level, and how complex the project is.

The 3 Main Types of CNC Programming

The 3 main types of CNC programming are:

- Manual CNC programming

- Programming with CAM software

- Conversational CNC programming

1. Manual CNC Programming

Manual CNC programming is programming a CNC machine by entering the g-code yourself, line by line.

CAM software has replaced the need to ever do this however. This is because writing g-code manually is time-consuming for simple operations, and almost impossible for complicated projects. Complicated toolpaths could have over a million lines of g-code, which would take years, and one mistake could ruin the entire job.

The main disadvantages of manual CNC programming include:

- Extremely time-consuming (except for very simple commands)

- Takes tremendous levels of calculations to interpolate curves.

- Impossible to create complex toolpaths with millions of lines

- Requires years of experience to write advanced g-codes

Today, CNC programmers only learn very basic manual programming commands so that if they see them, they can identify them. They may manually program very simple g-code, such as making small modifications like defining a tool offset, or finding simple errors.

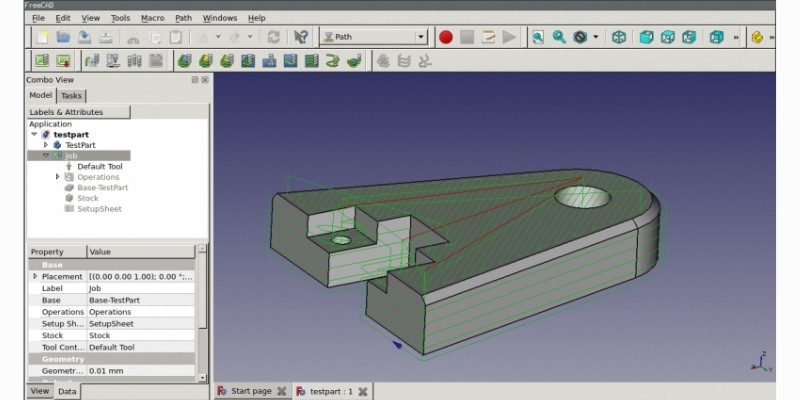

2. Programming with CAM Software

CNC programming with CAM software is essentially using a computer program to write teh g-code for you.

You can also select different features, and give the program instructions on what to do with them. It’s similar to conversational programming, but far more robust.

Simply put, there are things that are just too complicated to do without a CAM program. It’s near impossible to program g-code for machining a massive part with complex 3D geometry, for example.

There are a huge number of different CAD/CAM programs to choose from and narrowing down what works for you and your budget can get pretty involved. We’ve written extensively about this, and recommend the top CAD CAM program choices based on your preferences in our article.

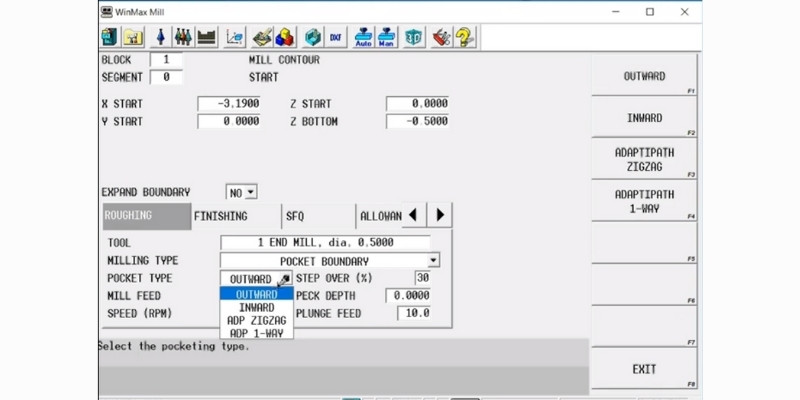

3. Conversational CNC Programming

Firstly, there is conversational programming. This is where the programmer is shown options for which types of tool, shape, and various other operations, and picks from these options.

It’s quick, it’s intuitive, and very effective at doing simple tasks. You literally tell the machine to cut this line or drill these holes, and the program is then converted into g-code for you.

With AI improvements, I think this will become much more powerful very soon. I predict you will within the next year be able to write a much more complex prompt in your software, and the machine will instantly adapt to this. Think of it as the CNC programming version of Midjourney or ChatGPT.

CNC Programming For Beginners – A Guide To Starting

Here’s some useful answers for beginner CNC programmers looking to learn how to program a CNC machine, or are looking to find out if this career is for them.

Is CNC Programming Hard?

The basics of CNC programming are easy to grasp, and can be learned in just a few days. But, complex CNC programming skills, such as programming a CNC mill to cut metal, can take years to master.

CNC programming’s difficulty depends on what you’re programming, and for what goal. Programming a 3D printer or laser cutter is fairly simple, but more complex tasks, with more axes and tougher materials, are far more difficult.

What Do You Need To Be A Good CNC Programmer?

To be a CNC programmer, you will need some math skills. But, computers can help with complicated aspects such a complex geometry or trigonometry.

I’m personally not good at math, but I’m a pretty good CNC programmer, so don’t be put off if you aren’t confident in your math skills.

To be a good CNC programmer, you also need to be able to listen and learn. You will likely never have done anything like this before, so you need to be teachable when you start.

Once you get the basics, then the next thing is being able to problem-solve. There is no hard and true way of programming a part. It’s as much art as it is application. Any experience with CAD (Computer-Aided Design) or CAM software is also a plus.

How To Learn CNC Programming

To learn CNC programming, it’s best to find an existing CNC shop, and ask if they are hiring. While there are classes you can attend that teach a lot of valuable information, I recommend learning within a shop as you’ll be working on real-life CNC programming projects.

Even if your end goal is to be a CNC programmer, I recommend that you start as a machine tool operator. You’ll be running a machine and learning the basics of machining, which will help you prepare for programming later on.

The CNC industry is built on the sharing of knowledge, and you may be surprised how eager people are to teach you. In fact, I’ve only ever worked with one person that went to college to be a CNC programmer.

Where To Learn CNC Programming

There are CNC programming college courses that you can take, as well as trade schools. But, honestly, I would steer you away from those.

If you are interested in learning how to program, you can get a basic idea of what it entails by watching YouTube videos. If it looks like something that you are interested in, then I would start applying at local shops.

Every shop I’ve ever worked at is always hiring. If you’re enthusiastic, even with zero experience, they will likely give you a shot. That said, it’s not easy, and not everyone succeeds in becoming a CNC programmer. You’ll learn pretty quickly whether or not you’ve got what it takes.

Some CNC Programming Tips For Beginners

I’ve trained about a dozen people over the years. Based on this, here are some tips for learning CNC programming:

- Honesty: The first and most important thing I teach is that you have to be honest. If you don’t understand something, speak up. You won’t be able to fake your way through it later. Pay attention, ask questions, and most importantly, don’t be afraid to say “I don’t understand that part.”

- Be curious and take action: When learning, look things up online, and watch YouTube videos while taking action and learning at a shop. College is not necessarily required, and you get all your training on the job when you learn in a shop.

- Be prepared for the future: Artificial intelligence will change how CNC programming works. But, there will always be a need for good CNC programmers. Even if robots take over the CNC operator’s position, with an arm that pushed buttons and loads the part, somebody will still need to program that arm. But, stay aware of the changing industry trends and learn the latest knowledge so you are not left behind.

What Software Do CNC Programmers Use?

Software used for CNC programming includes CAD (computer-aided design), CAM (computer-aided manufacturing), CAE (computer-aided engineering), simulation software, post-processor, and control software. These CNC programs are often integrated, for example Mastercam has CAD, CAM, and simulation features all in one.

Of these, CAD and CAM are the most important, requiring expertise and reflecting true CNC programming.

Here’s a quick breakdown of the main three types of CNC programming software:

- CAD: CNC programmers use CAD software to design the 3D part. Sometimes this won’t be required, for example, if you receive an order from engineers who have already designed the part.

- CAM: CAM software turns the 3D model into commands for the CNC machine. CAM software has a library of CNC tools and has strategies for planning the machine’s movement (tool path) to produce the g-code.

- Simulation software: The simulator software reads the g codes and simulates the job, helping to show up any issues that could affect the success of the job, before you waste the material or damage your CNC in the real operation. With this feedback, you can make changes to ensure everything goes smoothly.

Which Industries use CNC Programmers?

Almost everything that is manufactured is related in some way to CNC programming.

For example, in the automotive industry, CNC programmers instructed the CNC machine to cut and drill the car frame components. A CNC machine also produced the gears in the transmission. Every piece of plastic was extruded or pressed into a mold that was machined.

CNC programmers are involved in industries including:

- Defense

- Medical

- Aerospace

- Agriculture

- Space

- Electronics

- Plastics

- Cabinetry

- Signs

- Prototyping

CNC Programmer Career Outlook

CNC programmers are in high demand. They are needed in every facet of Industry and it’s not a very popular career path. You can find some useful statistics here, and at CNCSourced we also publish our own updated list of CNC industry statistics.

Here’s some career roles you may be interested in:

Machine Tool Operator

In most cases, you’ll start your career in CNC programming as a machine tool operator. Machine tool operators work directly at the machine, and are responsible for changing parts, measuring completed parts, and maintaining tooling.

Every shop does things differently, but you should expect to work as a machine tool operator for a year or two. You’ll pick up a massive amount of knowledge that will prepare you for the next step.

CNC Machinist

Once you’ve been a machine tool operator, the next stage is becoming a machinist. A CNC machinist’s role is to program and run their machine. They need to be intimately aware of the machine’s specifications and abilities.

A machinist is the person you give a cart full of material stock to, along with a blueprint, and when you return later, they’ve turned this into a stack of finished parts

CNC Programmer

A CNC programmer’s job is broader than a machinist’s, as they will have a lot of different CNC machines that they program for.

CNC programmers need to understand the shop’s capabilities as a whole, and which machine is best suited for any individual job.

Some shops have a handful of programmers supporting a large number of operators, while other shops might only have machinists. Every shop is unique in how they function.

Beginners who are seriously considering a career in CNC programming, also need to get familiar with CNC terminology and acronyms.

Examples of Software CNC Programmers Use

Here are some of the well-known software for CNC programming:

- Fusion 360: Very popular with small businesses and hobbyists, and has 5-axis features, and some CAE features.

- Mastercam: Popular among CNC programmers for its excellent CAM capabilities, and also has CAD, simulation and g-code editing features.

- SolidWorks: Popular with mechanical engineers and manufacturing, and is also somewhat used by CNC programmers with a range of free and paid CAM add-ons.

For more related topics, here are some articles we recommend:

- Great Laptops for CNC Programming

- CNC G Code Tutorial: G02 and G03 with I J K and R for Circular Interpolation

- Best G Code Editors: Offline & Online Options

- Best Cheap CNC Routers (Beginner & Advanced Machines)

- FreeCAD vs Fusion 360: Which CAD Software is Best For You?

- Coolest X-Carve Projects