Key Takeaways

- Air Assist Benefits: Air assist improves laser speed, quality, safety, and lifespan by blowing away smoke and debris.

- Air Assist Types: Air assist can use natural air, oxygen, or nitrogen gas. Natural air is cheaper and sufficient for hobbyists.

- Air Assist Control: Air assist can be controlled manually or by software. Some controllers and software support air assist functions.

- Air Assist Recommendations: The xTool D1 Air Assist Set is a low-noise and complete kit. The Amazon Air Assist Set is compatible with Ruida.

Tired of dealing with charred workpieces, slow job completion, and the risk of damaging your valuable laser equipment?

My detailed guide to laser air assist technology will walk you through my hands-on experience with the top commercial and DIY kits for enhancing your laser cutting and engraving work.

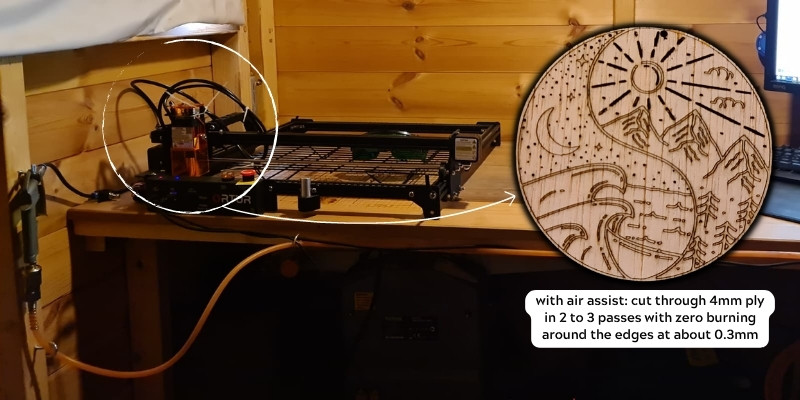

I’ll share the results of a test I ran with my low-cost laser engraver (the Ortur LM3), to show the advantages of adding a laser assist attachment to increase safety and efficiency.

As well as recommending some of the best air assist kits for lasers, I’ll also cover the tips and tricks you should know to get the cleanest cuts – like the best gases for your air assist and how to control air assist with every main laser software.

CNCSourced Recommended Air Assist for Lasers

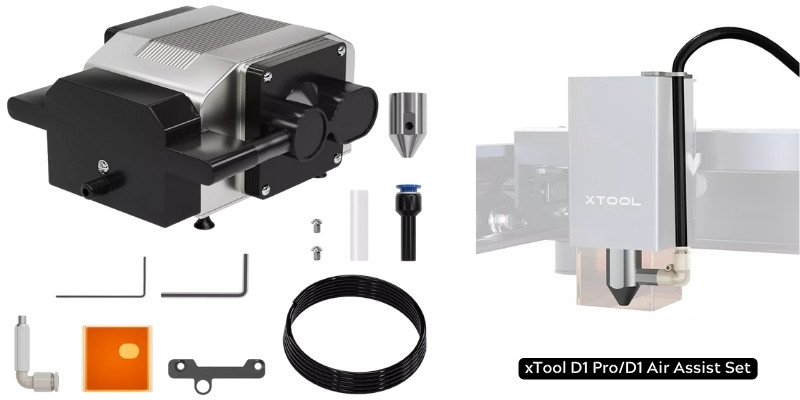

If you want an affordable air assist kit with a low-noise air pump, check out the xTool D1 Air Assist Set. Its quiet air pump is bliss since some air pumps are very loud.

This kit has everything you need. Plus, it has detailed instructions on how to connect it to your controller.

The xTool D1 can provide up to 30l/min while keeping quiet. More generally, we just think the xTool D1 Pro is the best diode laser around right now, and we’ve found xTool’s accessories to be of similar high quality. You can view the specs here, or read our comparison with the Ortur LM3.

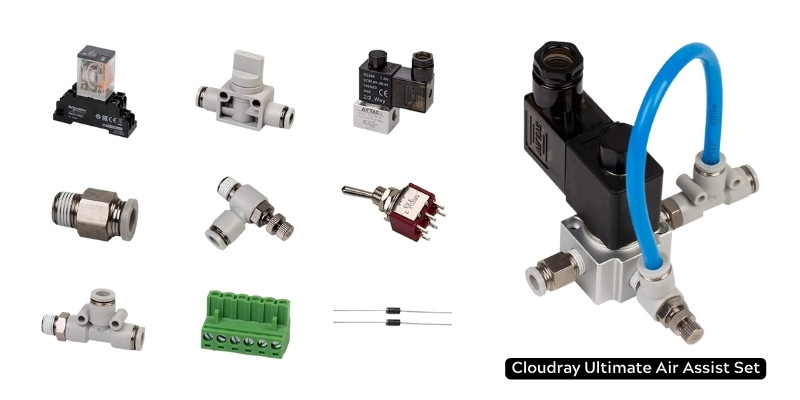

If you have an air compressor but not the rest of the equipment, there is a kit on Amazon for you.

With this air assist set on Amazon, you can connect your air compressor to your laser and controller. It has all the equipment (without the air pump) and is compatible with Ruida.

What Is Laser Air Assist?

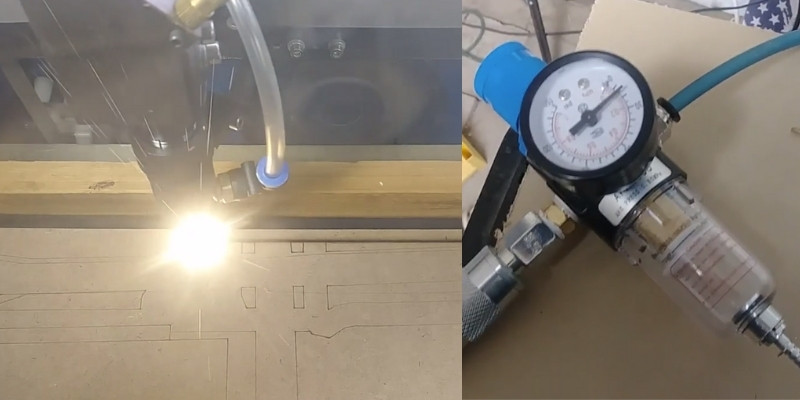

Anything that blows on the workpiece during laser cutting or etching is an air assist. So, air assist can be as simple as a fan. But usually you’ll have an laser air assist pump that attaches to a nozzle. Alternatively, a compressor can act as the air supply instead of an air assist pump.

The laser air assist nozzle sits where the laser head is. This way, the nozzle can blow directly on the area the laser targets and puff the smoke away from the laser head and the lenses.

Moreover, the compressor supplies pressurized gas to the nozzle so the nozzle can blow high-pressure gas from the compressor.

The compressor can be as small as 5l (5 liters), but 50l is more well-liked among laser users.

What are the Benefits of Adding Air Assist To a Laser?

The laser cutter air assist helps in many ways, including the following benefits:

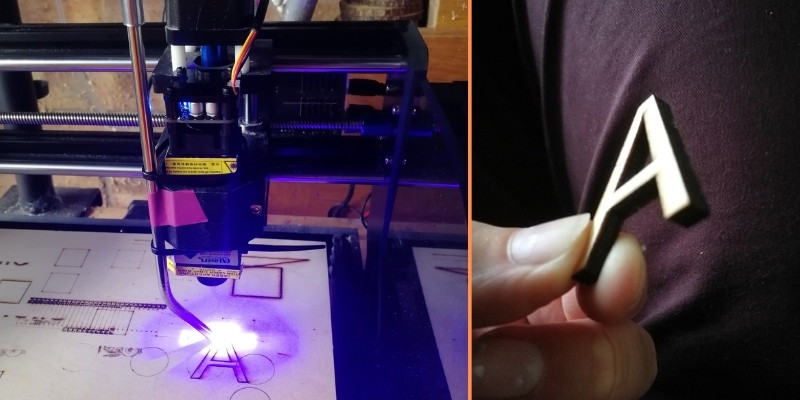

Air Assist Reduces Chars

For one thing, air assist reduces chars significantly. Especially with wood, some scorching around the edges is inevitable. You can spend time cleaning the chars off after the laser cutting wood.

But, air assist could save you from chars and grant you cleaner cuts. The air assist prevents chars by cooling the point of contact and keeping the surface from oxidation.

Air Assist Keeps the Smoke Away From Your Lenses

The cooling effect is not all the laser air assist brings to the table. Air assist also blows the smoke away from the lenses and the laser head.

Laser etching or cutting creates smoke and fumes that rise from the material. Gradually, these fumes gather on your laser’s lenses and decrease the quality of your laser beam.

Granted, you can clean the lens and other parts that have suffered from the fumes, but this is avoidable extra maintenance.

Air Assist Helps With Higher Quality Cuts and Engravings

Air assist also blows the debris away during the laser engraving process. If left on your material’s surface, the residues can worsen the quality of your cuts or engravings by getting in the way of your laser’s beam. But, a proper air assist keeps any residue and debris away.

You’ll Finish Jobs Faster

Air assist also enhances your laser speed. Laser power declines when unwanted residue and carbonized particles get in the way of the laser beam.

But, air assist clears your workspace, so your laser has a clean run at engraving away the wood, acrylic, or ny other material. This leads to a faster cut or clean engraving, saving you time and allowing you to run your laser faster and get the same results.

So, air assist improves the laser speed by enhancing the beam’s efficiency. For example, a 40W beam with 99% efficiency cuts faster than the same beam with 85% efficiency.

Air Assist Keeps Your Laser Head Cool

The workpiece is not the only part that benefits from the air assist’s cooling effect. The laser head is also cooled by the air assist, prolonging the laser’s lifespan.

Safety Improvements

Last, air assist prevents fires from breaking out. Without air assist, there is a small risk part of the material or the unwanted debris could set alight. So, air assist can improve your fire safety.

What Type of Gas Is Good for Air Assist?

The laser industry discovered the virtues of air assist over two decades ago before lasers were readily available or common among hobbyists.

Some industries used oxygen tanks, while others used nitrogen gas for its better cooling abilities.

Using pure oxygen or nitrogen requires large and expensive pressurized tanks. But using natural air has become extremely popular among hobbyists and many industrial laser operations. The air compressors use natural air to provide a steady current of high-pressure gas.

Using natural air is much cheaper than nitrogen or oxygen gas. But is it any good?

For starters, the air is 78% nitrogen and 21% oxygen. So, the natural air around us bestows a mixture of oxygen and nitrogen for free with 99% purity.

Plus, nitrogen gas shines in high-intensity jobs like laser cutting thick metals with high-quality edges.

So, as long as you are a hobbyist, buying nitrogen tanks for air assist brings very few benefits – that aren’t worth the added cost.

In short, natural air for air assist is fine for hobby-level jobs.

How Much Air Do You Need for Air Assist?

I mentioned earlier how air assist helps to improve your speed. But, is there such a thing as too much airflow?

Actually, yes. Feeding too much air into the air assist nozzle is a common mistake among beginner laser operators.

Too much air slows your processing speed instead of increasing it. This is due to worse heat transfer from the laser beam, slowing the laser’s cut speed.

Therefore, only use enough airflow to remove carbonized particles, cool the material, and keep the smoke away.

The amount of airflow you need depends on your job. For example, engraving does not produce as much residue particles and fumes as cutting.

So, Opt Laser recommends that you keep your airflow between 1-3 l/min for engraving. But you should supply between 10-15 l/min for cutting.

How to Control Air Assist With LightBurn (GRBL and Ruida)

You can turn on your air assist manually if your controller doesn’t support air assist. However, many lasers don’t have the circuitry for controlling an air assist attachment.

So, you’ll need to buy an accessory if you want to control your air assist from your chosen laser software. For example, Ortur and xTool lasers have their own optional air assist add-ons which attach to the laser.

In the meantime, if your controller supports air assist and you have taken care of the hardware side of it, you can control your air assist from the software.

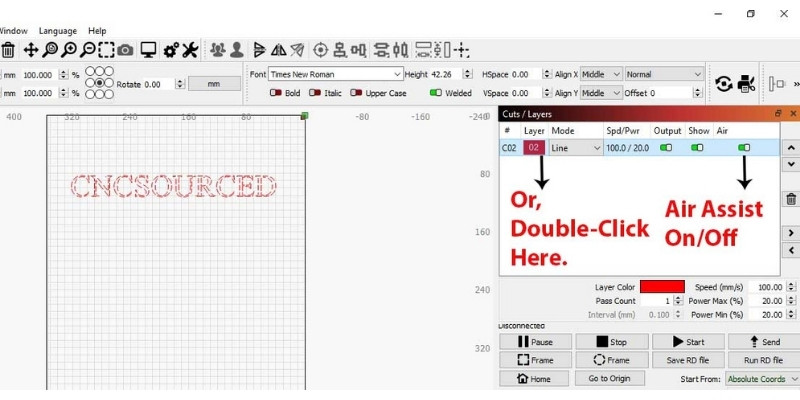

How to Control Air Assist From LightBurn With Ruida Controller

Ruida controllers can control your air assist. If you enable this function in the Ruida settings, you can manage your air assist from LightBurn.

You can specify whether to engage your air assist for different parts of your job in LightBurn.

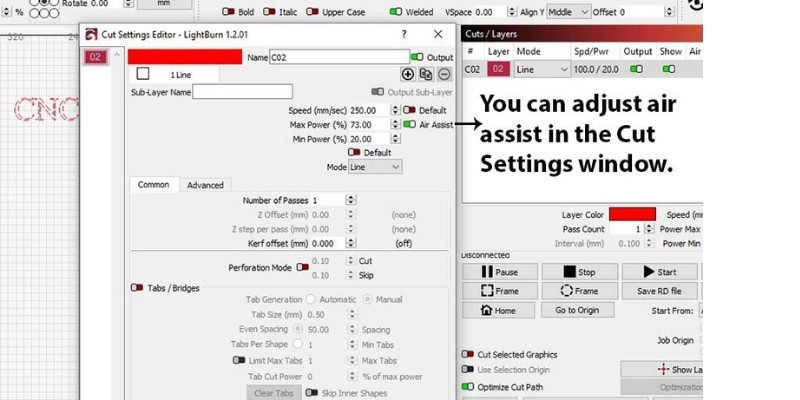

In LightBurn, go to the Layers tab where you can see your different layers. If you have quick access to Air in the layer description, you can simply switch it on or off.

Otherwise, you can double-click on any layer, and the Cut Settings window (for that layer) will pop up.

You can switch the air assist on or off on the right-hand side of the Cut Settings.

When the air assist is off in LightBurn, it still works on low pressure, but if you turn it on, it will bypass the limitation and make your air assist run at full pressure.

So, do not activate the air assist in LightBurn for engraving layers (so the air assist works at low pressure). But, switch the air assist on in the cutting layers to have the air assist run at full power.

What About Air Assist With GRBL Controller?

GRBL controller doesn’t have any pins for an air assist. Although there are tricks to work around this, I will not discuss manipulating your circuitry here. So, LightBurn can’t control your air assist if you have a GRBL controller.

However, you can always manually work with your air assist. You’re unlikely to need to turn off your air assist during a laser jo, so just turn it on before starting, and turn it off after finishing.

Summary

There are a lot of merits to using air assist in a laser.

Without air assist, your lens will get dirty before your third completed laser job. Laser air assist blows the carbonized particles away from the laser beam and reduces chars, and enhances your laser cutting safety by preventing flare-ups and fires.

Finally, air assist improves your laser speed by increasing your laser beam efficiency and allowing you to cut and engrave faster.

We’ve also made a video covering the main info if you prefer this:

Related Posts:

- Best DIY Laser Cutters & Engravers You Can Build At Home

- Top Cheap Laser Engravers/Cutters That Actually Work Well

- xTool D1 Pro vs Ortur Laser Master 3: Hands-On Comparison

- The 10 Best Laser Cutters & Engravers (Every Price Range!)

- Ortur Laser Master 3 Hands-On Review: Best Under $1000?

- Best Laser Safety Goggles for Every Wavelength