Wood is the most popular material for CNC routing, but with so many types of wood to choose from, it’s important to know which type is best suited for different projects.

In this guide, I’ll reveal the best wood for CNC routing. I’ve split this article into hardwoods, softwoods, and engineered woods to help you find the right material for whatever you want to make.

Best Woods For CNC Routing – Full Round-Up

Best Softwoods

- Cedar: For outdoor furniture such as benches, as well as for gates and fences

- Cypress: For furniture

- Spruce: For paper pulp, construction lumber, and use of sound boarding in musical instruments

- Fir: For structural work, carpentry, joinery, boatbuilding, and transmission poles

- Pine: For flooring, furniture, and structuring of many houses

- Redwood: For decking and outdoor structures such as fences, gates, and patio covers

- Yew: For archery bows, furniture and turned products

- Western red cedar: For routing

Best Hardwoods

- Birch: For brace and structural component in carpentry

- Ash: For staircases, moldings, doors, and flooring

- Beech: For routing and milling of tables, chairs, and similar products

- Walnut: For wood sculptures, carpentry and gunstocks

- Cherry: For musical instruments, such as guitars and drums

- Elm: For chairs, baskets, coffins, and sports equipment like hockey sticks and archery bows

- Mahogany: For premium furniture, musical instruments such as guitars, violins, and pianos and boat-making

- Maple: For 3D wood carving

- Padauk: For high-end furniture, knife and tool handles, and musical instruments

- Oak: For boat building, joinery, decking, flooring, furniture, and veneers

- Poplar: For furniture, fencing, and all types of other products and applications, including joinery and wood turning

- Alder: For carpentry, carving, woodturning and decorative products

Best Engineered Woods

Best Softwoods For CNC Routing

Cedar, cypress, pine, fir, and redwood are all considered among the best softwoods for CNC routing. Softwoods come from conifer trees, whereas hardwoods are deciduous. Softwoods are typically less dense than hardwoods.

Cedar

- Best for: outdoor furniture such as benches, as well as for gates and fences

Many CNCers favor cedar due to its distinct reddish hue and complex woody aroma. Its fantastic weather resistance means it’s often used for outdoor furniture such as benches, as well as for gates and fences.

Cedar also has good heat resistance and, unlike many hardwoods, doesn’t burn at slow feed rates. This means you can mill it slowly to prevent tearing, which is important as the knots in cedar can make it difficult to mill at high speeds.

Cypress

- Best for: furniture

Cypress is widely used in furniture as it’s decay resistant — although it’s slightly weaker than cedar. Cypress is generally less expensive than cedar however, but this depends on the woods’ age and knotting.

Like cedar, cypress contains knots, so you must take care especially when working on large pieces. However, as it’s slightly softer than cedar, it’s also easier to carve.

Spruce

- Best for: paper pulp, construction lumber, and use of sound boarding in musical instruments

Spruce has some fairly unique benefits and limitations. On the plus side, it’s one of the harder softwoods while still being fairly lightweight and easy to work with, provided the piece you have isn’t particularly knotty.

However, it doesn’t have the best decay resistance. Spruce is widely used for paper pulp, construction lumber, and also has the unique use of sound boarding in musical instruments due to its resonant properties.

Fir

- Best for: structural work, carpentry, joinery, boatbuilding, and transmission poles

Fir is easier to work with than knotted wood like Cedar and Cypress, thanks to its consistent pattern and lack of knots.

Fir is also one of the harder and most durable softwoods. This means that it’s very versatile and is used for structural work, carpentry, joinery, boatbuilding, and transmission poles.

Pine – best softwood for beginners

- Best for: flooring, furniture, and structuring of many houses

Like fir, pinewood is one of the harder softwoods. It’s generally fairly easy to machine, due to it being shrink resistant and holding its form well. You can reduce the risk of splintering by using smaller cutting lengths.

Pine can be a bit fuzzy, so it may require some extra sanding before and after cutting, but it’s very cheap and easily available. Light and pale in color, pinewood has a huge range of uses and is found in the flooring, furniture, and structuring of many houses throughout the world.

Redwood

- Best for: decking and outdoor structures such as fences, gates, and patio covers

Redwood is notable for its rich red coloring. It’s popular with woodworkers due to this color and also for being sun resistant, so it’s often used for decking and outdoor structures such as fences, gates, and patio covers.

Redwood’s softness means it’s often regarded as the best wood for carving projects. If you’re cutting, shallow cuts can help prevent splintering.

Yew

- Best for: archery bows, furniture and turned products

Yew is one of the hardest softwoods. It has a fine grain and smooth texture which make it an attractive finished wood, but it’s also typically very knotty, which can make it difficult to work with.

It’s also expensive and not very widely available. However, it has a unique mix of strength and flexibility, making it one of the most popular woods for archery bows. It’s also used in some furniture and turned products.

Western red cedar

- Best for: routing

Western red cedar is distinct from other cedar species due to its wide grain, as well as its darker coloring. The wide grains make it a good wood to work with for routing and it’s typically less knotty, but is also one of the more expensive softwoods.

Best Hardwoods For CNC Routing

Ash is widely regarded as the best hardwood for CNC routing, with beech, cherry, mahogany, and cherry being other popular options.

Hardwoods are more demanding on a CNC machine, so you’ll you need one that’s capable of milling these materials rather than a flimsy beginner router. Hardwoods also blunt your tools, so they’ll need to be replaced more often.

Birch – Best hardwood for beginners

- Best for: brace and structural component in carpentry

Birch is a very strong hardwood and very easy to work with, as it doesn’t dent or nick as much as others.

It has a light color with a wavy grain, and is one of the cheapest and most accessible woods. Due to its wavy grain, you should use a test piece and cut from different directions to find the one that causes the least splintering.

Thanks to its stiffness and ability to take screws well, birch is widely used as a brace and structural component in carpentry. It’s one of the most commonly used woods, and as well as furniture it’s used in everything from toys and crafts to broom handles and skateboards.

Ash

- Best for: staircases, moldings, doors, and flooring

Ash’s incredible strength and stiffness make it one of the most durable woods. It’s very dense and is used in products like staircases, moldings, doors, and flooring.

Ash also has an impressive mix of shock resistance and elasticity, which is why it’s often used for sporting equipment like baseballs and tennis racquets, drum casings, and also for wooden tool handles.

Ash is one of the lighter hardwoods in color and has lots of rings within its grain.

Beech

- Best for: routing and milling of tables, chairs, and similar products

Beech is arguably the most versatile hardwood, rivaling ash and birch in strength but with more elasticity, making it a popular choice for the routing and milling of tables, chairs, and similar products. It also turns well.

As it’s odorless, beech is also widely used for making wooden cutlery and kitchen equipment, although it’s not as suitable for carving due to chipping that can result from its hardness.

On the downside, beech is not as durable as some other hardwoods, which is why it’s not the best choice for outdoor products.

Walnut

- Best for: wood sculptures, carpentry and gunstocks

One of the most expensive woods, walnut boasts not only fantastic strength but also a very distinct dark brown coloring, making it a good alternative to the many lighter-colored hardwoods.

As it has straight grains away from the roots, walnut is easier to carve than many hardwoods and takes shocks very well. It’s also very burn resistant.

For these reasons, it’s typically the favored choice of wood sculptures, but is also widely used in carpentry and is particularly common in gunstocks.

Cherry

- Best for: musical instruments, such as guitars and drums

Cherry is one of the easier hardwoods to work with due to it being slightly softer than the likes of ash and beech. This, along with the fact that it doesn’t warp, makes it easier to cut and carve, but you still need to use sharp tools to avoid burn marks.

It’s also often considered one of the most beautiful woods to use in furniture and other products due to its light reddish hue and smooth finishing.

Cherry is a very versatile wood, being resistant to rot and shock, while also having good bending properties. It’s a popular choice for making musical instruments, such as guitars and drums, but is expensive.

Elm

- Best for: chairs, baskets, coffins, and sports equipment like hockey sticks and archery bows

Elm is another of the softer hardwoods. It has a pleasant medium tone and is very stress-resistant with a tight-twisted grain, making it a popular choice for making chairs, baskets, coffins, and sports equipment like hockey sticks and archery bows.

However, due to its course grain and open pores, it’s prone to tearing when you cut across the grain and so is requires a powerful spindle

Mahogany

- Best for: premium furniture, musical instruments such as guitars, violins, and pianos and boat-making

Mahogany is widely considered one of the most luxurious woods due to its rich color and vibrant appearance, which also makes it among the most expensive. It’s used in premium furniture and also in musical instruments such as guitars, violins, and pianos, among many other applications.

It’s also a popular choice in boat-making due to its high water resistance. Mahogany is very strong and resistant to warping, swelling, and shrinking, and is relatively easy to work with as it rarely tears out.

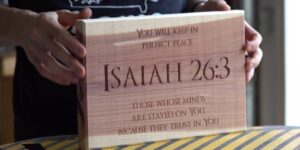

Maple

- Best for: 3D wood carving

Maple ranks among the hardest of all woods, requiring a high-strength CNC router and very sharp bits which will still be dulled after cutting. It’s also one of the more expensive woods, but is favored by many woodworkers due to its toughness and the fact that it stains easily.

Maple also has a uniform grain distribution, making it a popular choice for 3D wood carving.

Padauk

- Best for: high-end furniture, knife and tool handles, and musical instruments

Paduak’s straight grains make it another good hardwood for CNC carving as long as you’re using a sharp bit, although it is one of the dustier woods. It stands out for its dark coloring and distinctive grainy appearance, making it a popular choice in high-end furniture, knife and tool handles, and musical instruments.

Although not as expensive as the likes of mahogany, padauk is still pricier than most other woods.

Oak

- Best for: boat building, joinery, decking, flooring, furniture, and veneers

Another extremely hard wood, oak requires careful cutting with multiple short passes and you need to watch out for burning. However, it’s also one of the cheaper hardwoods. Both red oak and white oak are commonly used in CNC routing.

Oak’s strength, durability, and moisture resistance make it a popular choice in boat building. It’s also favored in joinery, decking, flooring, furniture, and veneers for its long-lasting durability and distinctive ring grain.

Poplar

- Best for: furniture, fencing, and all types of other products and applications, including joinery and wood turning

Poplar is a cheap, widely available hardwood that’s known for taking paint well, making it widely used in furniture, fencing, and all types of other products and applications, including joinery and wood turning.

This is one of the softer and easier-to-work-with hardwoods, but it does require a lot of sanding.

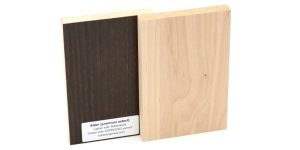

Alder

- Best for: carpentry, carving, woodturning and decorative products

Alder is another of the softer hardwoods. It has straight fibers with an even structure and is very pliable, so it’s commonly used in carpentry. It’s also one of the better hardwoods for carving, even if it can be a bit stringy, and is a fairly popular choice in woodturning and decorative products.

A cheap wood, alder has an even honey-like tone and can be finished to resemble more expensive types, making it a good budget option.

Best Engineered Woods For CNC Routing

MDF, plywood, and particleboard are the most widely used engineered woods in CNC routing.

Engineered woods are derivative wood products typically made by using synthetic adhesives. The main benefit of engineered woods is their low price, wide availability, and that they’re typically easy to cut.

MDF – Best engineered wood for beginners

- Best for: furniture like cabinets

The main benefit of MDF is that, while natural wood has good strength in one direction, MDF is equally strong in all directions.

This is because its structure isn’t patterned. This means MDF cuts much easier than most wood types and doesn’t break or splinter easily. It’s also very cheap and readily available.

However, this also means MDF doesn’t provide the nice natural colors, patterns, and knots you get with natural wood, so most MDF products are painted. On top of that, MDF is not as strong as solid wood, so you wouldn’t want to use it for a chair, for example. It is, though, widely used in affordable furniture like cabinets.

Another thing to bear in mind is that because it’s partly composed of adhesive resin, MDF burns easier than most other woods, so you need to be careful with feed rates. You also need a mask and dust collection system in place to prevent you from inhaling the particles that are produced when you cut MDF.

Plywood

- Best for: structural applications, such as sheathing, partitions, floors, and interior vehicle bodywork

Plywood is made from thin sheets of wood veneer that are glued together, with the sheets’ wood grains rotated up to 90 degrees to each other. Plywood can be made from various wood types, such as birch plywood and pine plywood. You can have both hardwood and softwood plywood.

It’s very inexpensive and lighter than natural woods, while also retaining good stress and weather resistances, Plywood is used in structural applications, such as sheathing, partitions, floors, and interior vehicle bodywork.

While MDF is good for carving, plywood is less so as it’s more prone to splintering.

Particleboard

Also known as chipboard, particleboard is similar to MDF in that it’s made of wood and synthetic resin, but particleboard is made up of chips rather than wood residue. This makes it less smooth and dense, but particleboard is cheaper.

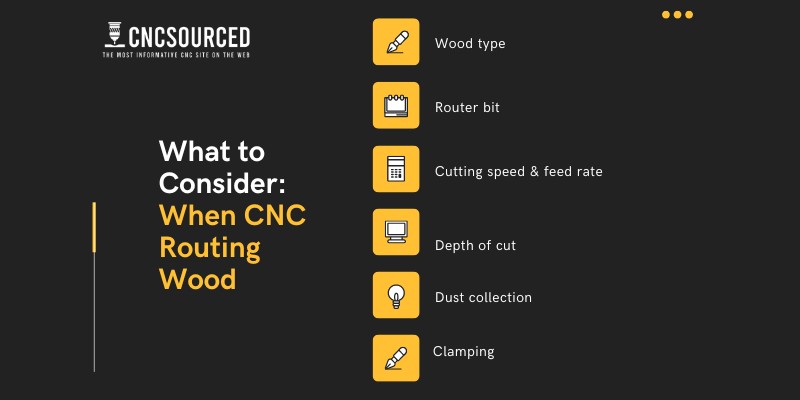

How To Pick Wood For Your Next CNC Project

Wood type

First off, you need to find the right wood for what you want to do. It needs to be strong enough for what you want to make and suitable for your CNC router to handle – some budget CNC routers will struggle with some hardwoods, for example.

You can check out our guide on the best CNC routers for wood to see the top machines for working with hard and softwoods.

You also need to consider the knotting and risk of splintering, as these impact how difficult the carving process will be. For example, redwood and MDF are easier to 3D carve than beech and plywood as they’re less likely to splinter. Other factors, such as color and aroma, don’t impact the cutting process but are important to consider for your end product.

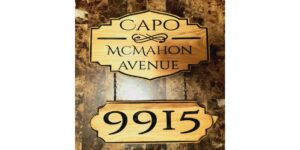

Router bit

It’s important to have the right size and shaped router bit for the type of cutting and carving you want to achieve. For example, spiral bits are better for straight cuts, ball nose bits are best for 3D carving and contouring, while v-bits are preferred for lettering.

You also need to make sure the bit is sharp. If you use an old tool that’s blunted, you’re not going to achieve clean or fast cutting, particularly on hardwood. For the hardest woods, you should consider using a carbide-tipped bit for the best results and the most resistance to dulling.

Cutting speed & feed rate

It’s important to determine the right feed rate when woodworking, low feeds can risk burn marks while high feeds can increase the risk of splintering.

Some CNC machine manufacturers state the suitable feeds for different materials in their documentation, but you can also use online forums and feed calculators to get a better understanding.

It’s always advisable to do a test run on a scrap piece of the wood you’re using to help determine a suitable feed rate.

Depth of cut

Cutting too deep in a single pass can cause wood to splinter, so it’s best to start with shallow cuts to help prevent this. Different wood types are more susceptible to splintering than others, so it’s important to be aware of this.

Dust collection

CNC routing causes small chips and dust to emit from your workpiece, so you need to have a suitable dust collection in place to keep your workpiece and workplace tidy, and also to prevent you breathing in any particles.

You should also consider wearing goggles and a mask. The latter is particularly important if you’re cutting MDF and other engineered woods, as they can produce very fine particles and fumes that can be harmful if breathed in.

Clamping

If your wood isn’t securely clamped down, it may move during the cutting process and mess up your work.

Where to buy wood for CNC Routing

- Home Depot

- Lowes

- Probotix

- Hardwood suppliers