Key Takeaways

- NC vs CNC: NC (numerical control) and CNC (computer numerical control) are two types of machining tools that transform stock materials into finished products or parts.

- NC features: NC machines are controlled by prerecorded information and punched tape. They are cheaper, simpler, and more skillful than CNC machines, but also more time-consuming, less accurate, and less flexible.

- CNC features: CNC machines are controlled by computer software and G-code. They are faster, more precise, and more complex than NC machines, but also more expensive, less skilled, and more wasteful.

- CNC advantages: CNC machines can produce high-quality, intricate, and customized shapes and designs with minimal error and repetition. They can also be easily modified and altered on the computer.

CNC (computer numerical control) and NC (numerical control) are two different types of machining tools. They both transform stock materials into a finished product or part.

The main difference between NC and CNC is that CNC is computer controlled, while NC is controlled by prerecorded information and punched tape.

Besides CNC being more advanced and NC being more rudimentary, there are lots of other differences between these two tools.

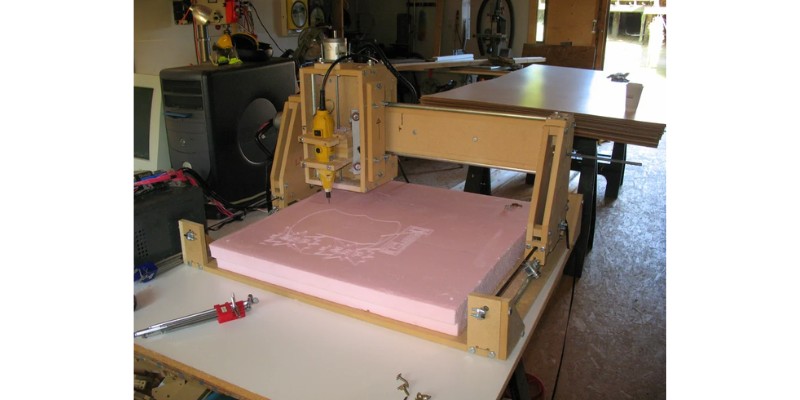

What is a CNC Machine?

With CNC machines, you can manipulate tools in any way you want using a computer. These digital instructions are called ‘G-code’, which you can write using a CAM or a CAD program.

Instead of manually writing out G-code, you can build your project on a computer program. Then, you can build the tool path from the digital model and get the G-code. This code can be read by the CNC machine tool to construct the physical parts.

Both CNC and NC machines work by commanding several tools to make changes to the stock material. With CNC machines, these tools are saved in a digital tool library.

What is an NC Machine?

NC machines, on the other hand, rely on instructions via ‘punched tape’. NC machines were the first of their kind, having started back in the 1940s. Groundbreaking at the time, NCs replaced manual wood and metal work with self-moving tools.

Instructions in this tape come in numbers, letters, and other symbols. Specific symbols match up with specific machine commands. So, you need to select the correct symbols based on what you want the machine to do. Then, you have to feed this into the NC machine.

Once you feed this punched card into the machine, it goes to the Machine Control Unit (MCU). The MCU can interpret the data presented on the card. From this, the MCU can carry out actions as informed by the punched tape.

Key Differences between NC and CNC

NC and CNC machines are mostly similar; they’re both used to make products and parts. Specifically, both machines can be used in engineering, construction, and manufacturing industries.

Input

CNC machines are fed instructions through a computer program, hence their title ‘computer numerical control’.

NC machines, on the other hand, are given controls via punched cards. These cards contain commands that correspond with preprogrammed settings.

Capabilities

CNC is the preferred machine tool for advanced designs, including complex geometries.

NC is not recommended for complex geometries. It’s much better suited for simple shapes and carrying out fixed logical functions.

Modification

CNC programming can be modified easily on the computer. There are even powerful free CNC CAD/CAM software tools now (some are even browser-based), as well as CNC simulators that simulate the cutting process to spot any potential issues.

To modify an NC machine program, you must alter the data presented on the punched tape.

Operation parameters

Operational parameters can easily be altered on a CNC machine.

You cannot alter operational parameters on an NC machine.

Storage

You can easily use computer chips for storing memory for a CNC machine.

For NCs, your only method of information storage is through punched cards.

NC vs CNC Comparison

To answer the question ‘what’s the difference between NC and CNC machine tools?’ here’s a table to demonstrate the contrasts between the two:

Cost

| Machine | Cost |

|---|---|

| NC | Cheaper than a CNC machine. |

| CNC | With all that said about CNC machines, one might wonder, “How much does a CNC machine cost?” Costs more than an NC machine. They generally range between $5,000 and $200,000. Budget options are available, such as the Sainsmart 3018 ProVer, which costs around $300. |

Maintenance cost

| Machine | Maintenance cost |

|---|---|

| NC | Minimal maintenance cost. |

| CNC | Generally more expensive to maintain. |

Accuracy

| Machine | Accuracy |

|---|---|

| NC | Relying only on punched tape instructions, NCs are less accurate than CNCs. |

| CNC | Being computer-controlled, CNC machines deliver greater accuracy. |

Operator skill level

| Machine | Operator skill level |

|---|---|

| NC | It requires an advanced understanding – comprehension of relevant symbols and an understanding of how to create punched tape instructions are necessary. |

| CNC | Only a basic understanding of computer machining process is necessary. The Inventables X Carve is good CNC router for beginners. However, for more complex milling operations, such as on CNC machines with 5 axes, these can require expert knowledge. |

Flexibility

| Machine | Flexibility |

|---|---|

| NC | There’s less flexibility with NC as prerecorded commands are limited. |

| CNC | CNC offers great flexibility, being compatible with several computer programs. |

Time consumption

| Machine | Time consumption |

|---|---|

| NC | Much more time is necessary to set up an NC machine. |

| CNC | Operations can be completed on a CNC machine quickly. |

Memory storage

| Machine | Memory storage |

|---|---|

| NC | No memory storage. |

| CNC | Lots of memory storage. |

FAQs

What are some disadvantages of NC machines?

The main disadvantage of direct numerical control machines is they are time-consuming. It can take a while to set up the punched tape required to control the NC systems. Furthermore, it takes a skilled operator to control an NC system. Even a skilled operator could make a mistake in the punch system.

Another disadvantage of an NC machine is that the punched tape can suffer from wear and tear over time. This increases the maintenance costs of this machine control system.

What are some disadvantages of CNC machines?

While CNC machines have a host of advantages over NC machines, there are several drawbacks to the modern machining process. One is that it requires fewer skills to use a CNC machine than an NC machine. While this can be viewed as an advantage, it means that the CNC machine operator is less skilled. They don’t learn as much as the NC operator.

Another disadvantage is the cost of this machine tool. Not only is it expensive upfront, but computer numeric control units are also costly to maintain. Luckily, CNCs are becoming more common, with plenty of affordable options now available.

Lastly, it could be argued that the rise of the computer numerical control machine leads to unemployment.

What are some advantages of NC machines?

The main advantage of an NC machine is that it is much cheaper to control and maintain than a CNC machine. It also has various advantages over manual labor, including that it requires a smaller workforce. It also takes up less floor space than manual labor operations and reduces the risk of human error.

What are some advantages of CNC machines?

CNC machines are faster to operate. Unlike NC machines, they don’t require the user to fill out a punched card. Instead, computer systems and machine control units (MCUs) are used.

Another advantage of the CNC machine is that projects don’t need to be carried out more than once. Once you’ve used to cutting tool to create a desired shape, the CNC machine can replicate the same shape as many times as required. The CNC machine is more reliable and can create shapes and intricate designs more accurately.

Can a CNC machine tool be wasteful?

Both NC and CNC machine tools can be wasteful, mainly due to the amount of scrap material produced. Even with a skilled operator, there’s always going to be leftover material.

Is there a future for CNC tools?

A main difference between NC and CNC machine tools is that there is more of a future in CNC tools. CNC machine capabilities will continue to grow in complexity.

Final Thoughts

A CNC machine is a more advanced version of an NC machine, which can be controlled via computer software (hence why it is called computer numerical control). While NC tools can still serve a purpose, they require more skill, time, and effort than a CNC machine.

If you want a machine that offers better accuracy and is less time-consuming, a CNC machine would be the best option. Alternatively, if you want to use a machine that requires more skill and costs less, an NC machine would be the better option for you.

Recommended articles for further reading: