Key Takeaways

- CNC machines: CNC machines are computer-controlled machines that can perform various tasks, such as cutting, drilling, engraving, and 3D printing. They use different tools and methods depending on the material and the desired shape.

- CNC milling machines: CNC milling machines are used to make metal parts with high precision and accuracy. They have a movable bed and a spindle that moves up and down. They can have three or more axes and use different types of bits and end mills.

- CNC routers: CNC routers are used to cut sheet materials, such as wood, plastic, and foam. They have a large bed and a gantry that holds a spindle. They use router bits with various shapes and sizes to create patterns and features.

- CNC lathes: CNC lathes are used to make cylindrical parts, such as gears, shafts, and pistons. They rotate the workpiece while the cutting tools remain stationary. They can have two or more axes and use different types of tools, such as drill bits, taps, and grinding wheels.

There are 15 different types of CNC machines, each with their own unique capabilities. The most common types include milling machines, lathes, routers, and grinders.

These are the 15 types of CNC I’ll cover in this article:

- CNC router machine

- CNC mills

- CNC lathe machines

- Wire EDM

- EDM

- CNC laser cutting machine

- CNC grinders

- CNC plasma cutting machine

- CNC Oxy-fuel cutter

- CNC waterjet cutter

- Drilling CNC machine

- CNC drag knife and tangential knife CNC

- 3D printer

- CNC bending machines

- Pick and place machine

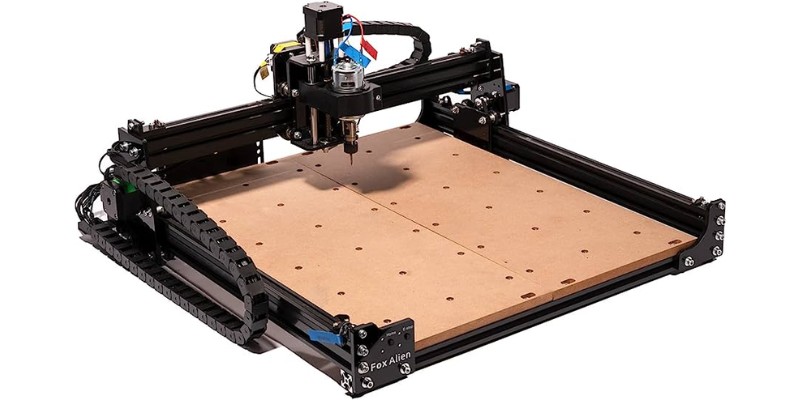

1. CNC Routers

- Price Range: $300-$400,000

- Used For: cabinet making, custom cutting material sheets

- Material Compatibility: wood, PVC, MDF, foam, plastic, glass, acrylic, and stone sheets

- Main Brands: Inventables, Carbide 3D, Sainsmart, Mori, Okuma, Laguna

- CNC machine tools: spindle cutting with endmills

- Desired shape: 3D patterns

- Industrial tolerance: 0.005″-0.03″ (0.13-0.76mm)

CNC routers have a large bed for laying sheet material. They use a spindle that takes inserts (end mills) with various shapes for cutting.

A CNC router has a gantry, which is a frame with arms on either side that holds the spindle. This type of CNC machine can handle large sheets of material, but it’s not strong enough to cut metal with great precision.

CNC routers are not as rigid as CNC milling machines. They’re great for woodworking and cabinet making, as well as some other industries.

In another article, we examined the best CNC router accessories and how they may make cutting, scoring, and engraving much simpler for you.

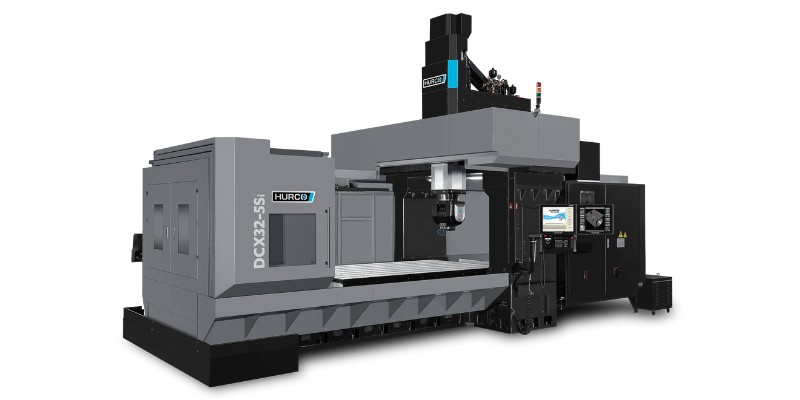

2. CNC Milling Machines

- Price Range: $2K-$500K+

- Used For: part making, gears, metal parts for cars, planes, etc.

- Material Compatibility: CNC machining metals (steel, aluminum, brass, zinc, titanium), thermoset plastics

- Main Brands: Mazak, Haas, DMG Mori, Doosan, Okuma, Makino, Fadal, Nakamura

- CNC machine tools: spindle cutting

- Desired shape: 3D patterns

- Industrial tolerance: 0.002″-0.005″ (0.05-0.13mm)

CNC milling machines are used in many industries to make metal parts. They have a movable bed and a spindle that moves up and down. CNC milling machines are very strong and accurate, which makes them perfect for precision machining. These machines typically have three or more axes, which allows them to create complex shapes.

The 3-axis CNC milling machine approaches the workpiece’s plane only from one angle, but 5-axis CNC milling machines tool the material from all possible angles, and can make extraordinary metal parts.

Vertical Machining Centers

A Vertical Machining Center (VMC) is a type of CNC milling machine that uses an automatic tool changer to switch out cutting tools. VMC machines are typically enclosed and have more axes than other types of CNC mills, making them more rigid, accurate, and expensive. They can cost upwards of $500,000.

3. CNC Lathes

- Price Range: $2K-$500K+

- Used For: part making, gears, metal parts for cars, planes, etc.

- Material Compatibility: metal CNC machining (steel, aluminum, brass, zinc, titanium), thermoset plastics

- Main Brands: Mazak, Haas, DMG Mori, Doosan, Okuma, Makino, Fadal, Nakamura

- CNC Machine Tools: Cutting tools and possible live tools

- Desired shape: cylindrical symmetry(2D) and possible 3D patterns

- Industrial tolerance: 0.002″-0.005″ (0.05-0.13mm)

CNC lathes are turning machines that rotate the workpiece while the cutting tools remain stationary.

Lathes are accurate and can handle tough materials, just like CNC mills. CNC lathes are better at making cylindrical parts, while CNC mills are better at creating various patterns.

Traditional CNC lathe machines have two axes. Modern CNC lathes, on the other hand, have live tooling and more axes. These types of CNC machines are a hybrid of CNC mills and CNC lathes.

Horizontal machining center (HMC)

A horizontal machining center is a CNC lathe that uses an enclosure and automatic turrets to change tools. The Z axis lies horizontally in these machines, hence the name “horizontal.” They have many servo motors and spindles, making them very expensive. Prices can range above $500,000.

4. Wire Electric Discharge CNC Machines

- Price Range: $7K-$200K

- Used For: cutting metal

- Material Compatibility: metals, graphite, any conductive material

- Main Brands: Mitsubishi, ONA, Makino, FANUC, Sodick, Agie, Brother

- CNC Cutting Tool: Wire electrode

- Shape capability: 2D cut-through from the edge or a predrilled hole

- Industrial tolerance: 0.0002″ (0.005)

Wire EDM machines use a hot wire to cut conductive materials. The wire can start cutting from the edge of the material or be passed through a hole in the part prior to cutting. This allows for precise cuts in complex shapes.

A wire EDM machine uses a thin wire electrode to cut through a workpiece by repeatedly discharging electricity between the wire and the workpiece. The workpiece is submerged in a dielectric fluid, which helps to insulate the workpiece and conduct the electricity.

Wire EDM machines can only cut through the workpiece, and cannot carve or engrave the surface.

5. CNC Electrical Discharge Machines EDM

- Price Range: $7K-$200K

- Used For: mold manufacturing processes, plastic mold injection, milling, and carving tough metals like titanium

- Material Compatibility: metals, graphite, any conductive material

- Main Brands: Mitsubishi, ONA, Makino, FANUC, Sodick, Agie, Brother

- CNC Machine Tools: copper or graphite electrode

- Shape capability: 3D pattern

- Industrial tolerance: 0.002″-0.005″ (0.05-0.13mm)

CNC electrical discharge machines (EDMs) use the same spark technology as wire EDMs, but they work in a different way.

Instead of using a wire electrode, CNC EDMs use graphite or copper electrodes. The electrode is machined on a CNC mill to create a negative of the desired cutting pattern.

The electrode is then lowered into close proximity to the workpiece surface. Sparks are generated between the electrode and the workpiece, which erode the material away until the electrode’s shape is copied.

CNC EDMs are used to create complex shapes in hard materials that would be difficult or impossible to machine with other methods.

6. CNC Laser Cutting Machines

- Price Range: $200 to $600K+

- Used For: cutting metals and non-metals, engraving, etching, marking

- Material Compatibility: wood, acrylic, metals, cardboard, fabric

- Main Brands: xTool, OMTech, Glowforge, Trumpf, Bystronic, Tanaka & Koike, Amada, Mazak, Mitsubishi, Salvagnini

- CNC Cutting Tool: laser beam

- Shape capability: 2D cutting and engraving

- Industrial tolerance: 0.005″-0.01″ (0.1-0.25mm)

CNC laser cutters use a laser beam to cut or engrave materials. They use the same gantry design as CNC routers, but with a laser beam instead of the router bit.

The laser beam is controlled by computer numerical control (CNC), which means that the path of the cut is programmed by a computer. The intensity and speed of the laser beam can be adjusted to create different cuts, or just to etch the surface of the material.

CNC laser cutters are excellent for engraving a wide range of materials with fine patterns or images.

Powerful industrial laser cutters are also excellent for cutting sheet metals and other sheet materials. They have the smallest kerf of cut (the width of material removed with the cutting tool) besides wire EDMs. Laser cutters have lower operating costs than plasma cutters and CNC waterjet cutters. However, they are not as fast as wire EDMs and cannot cut conductive materials.

Overall, CNC laser cutters are versatile machines that can be used for a variety of tasks. They are a good choice for businesses that need to cut or engrave materials.

7. CNC Grinding Machines

- Price Range: $8K-$1M+

- Used For: tool making, OD grinding, ID grinding, surface finish

- Material Compatibility: anything solid

- Main Brands: DMG Mori, Studer, Okuma

- CNC Cutting Tool: grinding wheel, possible insert grinder

- Shape capability: cylindrical symmetry (inside and out), possible 3D pattern

- Industrial tolerance: 0.002″-0.005″ (0.05-0.13mm)

CNC grinding machines remove materials from a workpiece with a rotating grinding wheel.

CNC grinders are known for:

- Offering some of the best surface finishes of any CNC machine type

- Machining the hardest materials

- Having the highest material removal rate

A grinding wheel is a tough, rotating disk with abrasive grits bonded to it. It can machine even the toughest materials, like carbide. In fact, the insert tools for other CNC machines are made on a CNC grinding machine center.

There are two main types of CNC grinding machine:

Cylindrical Grinders

Cylindrical grinders combine a CNC grinder and a CNC lathe. Cylindrical grinders are widely used in making cylindrical metallic parts.

This type of CNC’s most prominent operations are OD grinding (removing materials from the outer diameter) and ID grinding (removing materials from a hollow cylinder’s inner diameter). Such CNC grinders can make pistons, spline shafts, gear shafts, and brake cylinders.

Surface Grinders

CNC surface grinders, unlike cylindrical grinders, can machine the workpiece’s surface and even create 3D convex or concave patterns on it.

8. CNC Plasma Cutting Machine

- Price Range: $5K-$100K+

- Used For: cutting metals and electrically conductive materials

- Material Compatibility: metals, conductive materials (less common use)

- Main Brands: Laguna, Motorsports, Baileigh, Firebird

- CNC Cutting Tool: plasma torch

- Shape capability: 2D cutting

- Tolerance: 0.015″-0.03″ (0.35-0.8mm)

CNC plasma cutting machines are similar to laser cutters, but instead of a laser beam, CNC plasma cutting involves a plasma torch.

Plasma is a gas that has been heated to the point where its atoms lose their electrons. Plasma cutters use a nozzle to contain pressurized gas (oxygen, nitrogen, or natural air) and an electrode. The electrode is charged with a power supply, which ionizes the gas in contact with it. The plasma arc then travels through the nozzle towards the conductive material and cuts it.

Plasma cutters are excellent for cutting tough metals like steel, and they can cut both thick and thin metal sheets. But, they are only 2D cutting machines, and cannot cut any 3D shapes, like standard laser cutters, and 3-axis CNCs.

9. Oxy-Fuel CNC Machine

- Price Range: $4K-$100K

- Used For: cutting very thick ferrous metals

- Material Compatibility: ferrous metals

- Main Brands: Torchmate, FabCut

- CNC Cutting Tool: oxyfuel torch

- Shape capability: 2D cutting

- Tolerance: 0.02″-0.03″ (0.5-0.8mm)

Oxy-Fuel CNC machines use CNC technology to guide an oxyfuel torch. Oxy-fuel cutting involves heating the metal up to its ignition temperature and then, shooting a jet of oxygen at the metal to cut it.

The oxygen reacts with iron at high temperatures, and the high-speed flow of gas removes the iron oxide layer, cutting the metal and washing away the rust. This type of CNC can cut metals as thick as 6-20 inches. However, oxy-fuel cutting only works with ferrous metals.

However, it’s less accurate than other CNCs, because oxy-fuel cutting leaves a wide kerf with some kerf inconsistencies.

Oxy-fuel CNC tables cut parts that are then used in more precise machining processes. For example, a CNC grinder or a CNC lathe can be used to finish the surface of an oxy-fuel cut part with high accuracy.

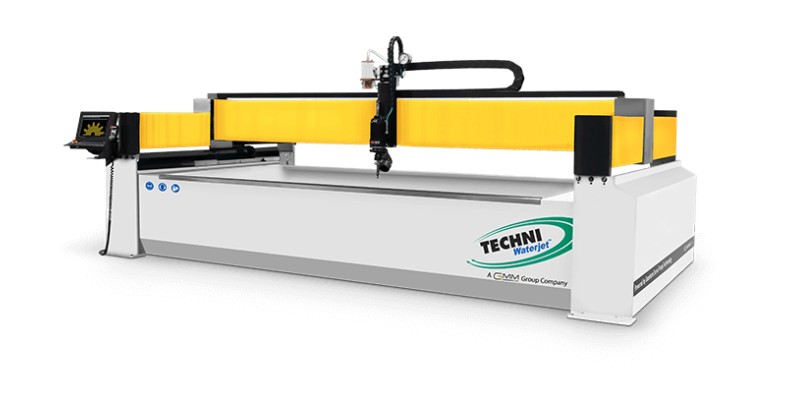

10. CNC Waterjet Cutting Machine

- Price Range: $4K-$100K

- Used For: cutting stone, tiles, glass, ceramics, plastics

- Material Compatibility: anything

- Main Brands: Omax, Sugino, Flow, KMT, Bystronics, CMS, Dardi, Resato

- CNC Cutting Tool: waterjet

- Shape capability: 2D cutting

- Tolerance: 0.01″-0.03″ (0.25-0.8mm)

CNC water jet cutters spray a high-pressure stream of water mixed with abrasives. The high pressure breaks down the material, allowing the cutter to cut through it.

Using CNC controls, the CAM software (computer-aided manufacturing) specifies the speed for the CNC water jet cutter to move the waterjet nozzle.

CNC water jet cutters are more accurate than CNC plasma cutters and Oxy Fuel CNC tables. However, CNC water jet cutters demand much more maintenance than CNC plasma cutters.

11. CNC Drilling Machines

- Price Range: $2K-$300K

- Used For: drilling plates and wood sheets and cabinet making

- Material Compatibility: all materials (wood, metals, stones, plastics, etc.)

- Main Brands: Voortman, ONA, AKYPAK, Nanxing

- CNC Machine Tool: drills

- Shape capability: holes

- Tolerance: 0.003″-0.005″ (0.07-0.13mm)

CNC drilling machines are used for precisely drilling holes in the workpiece for attaching other pieces.

Drilling only pushes the drill in and out of the workpiece, while other CNC machining types move a tool in all directions.

12. CNC Drag Knife, CNC Tangential Knife, and Oscillating Knife

- Price Range: $1K-$20K+

- Used For: cutting soft materials

- Material Compatibility: foam, rubber, textiles, fiberboard, vinyl, sandblast foil, flex, flock

- Main Brands: DMS, Summa, Aimark, GRIMCO, AXYZ

- CNC Machine Tool: drag knife, tangential knife, or oscillating knife

- Shape capability: 2D cutting

- Tolerance: 0.004″ (0.1mm)

CNC drag knife machines use a knife to cut soft materials like foam and rubber that CNC routers struggle to cut. CNC drag knives are similar to CNC routers, but they have a sharp knife cutter instead of a spindle.

Types of CNC knife cutters vary depending on the type of knife they use.

CNC drag knives are the simplest, putting the blade in the material and dragging it until the cut is finished.

Another type of CNC knife cutter is the tangential knife. Tangential knives can pull the blade out, spin it 90°, and put it back in for cutting. Certain materials like rubber will bend when a drag knife moves to the side at higher speeds, but a tangential knife can always redirect the blade.

Finally, oscillating tangential knives have a motor that moves the knife up and down, while another motor can rotate the blade like a tangential knife. This type of CNC knife cutter can cut even small contours (cutting small contours on soft materials like foam and rubber is difficult since they bend).

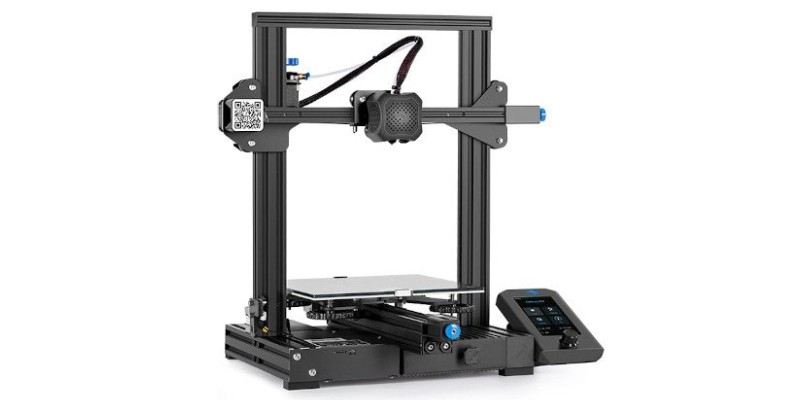

13. 3D Printers

- Price Range: $300 to $500K+

- Used For: additive manufacturing processes

- Material Compatibility: plastic (PLA, ABS, PVA, Polyamide), metals (stainless steel, gold, aluminum, titanium, bronze), graphene, polymers (PEEK, PEI, PPSU, PPSF), resin, carbon fiber, nitinol, paper

- Main Brands: Creality, Anycubic, Elegoo, Snapmaker, Stratasys, EOS GmbH, 3D Systems, Voxeljet AG, XYZprinting

- CNC Machine Tool: diverse methods depending on the machine – most common is a nozzle melting filament

- Shape capability: 3D objects

- Tolerance: 0.004″-0.012″ (0.1-0.3mm)

A 3D printer prints parts by adding material, layer-by-layer. Unlike other CNC machining techniques that are subtractive (they remove material from a workpiece block), 3D printers are a form of additive manufacturing. But, they are still CNC machines.

There are many methods of 3D printing: fused deposition modeling, stereolithography, selective laser sintering, multijet fusion, and more. But at the hobby level, the most common types of 3D printers use FDM (fused deposition modeling), or LCD, which is a form of resin printing.

FDM 3D printers use a filament, which is a coil of long and narrow string of thermoplastic. They have a nozzle that’s heated at the end (called the hot-end). This heat melts the filament, just like a glue gun, and then the extrusion system feeds this filament thorough the nozzle and deposits it on the print bed.

14. Bending CNC Machines

- Price Range: $4500-$80K

- Used For: bending pipes, tubes, and metal plates

- Material Compatibility: pipes, tubes, and metal sheets

- Main Brands: AMADA, TRUMPF, Bystronic, Gasparini, Salvagnini, Shenchong

- CNC Machine Tool: rotating arm or pressing block

- Shape capability: bent tubes and plates

CNC bending machines are specialty machines that bend material. The most common types of CNC bending machines are CNC tube bending machines, and CNC plate bending machines.

They are often used to bend metal tubes and pipes for HVAC systems (heating, ventilation, and air conditioning), automotive components, and more.

Pipe bending CNC machines can bend a pipe at any length, and to any degree. They have a chuck that holds the pipe, and move the pipe horizontally to adjust where it will be bent, and also rotate the pipe to adjust the direction of the bend. When the pipe reaches the point of bend, the clamping station holds it firmly, while the bending arm rotates to bend the pipe.

Meanwhile, plate-bending CNC machines are used to bend metal sheets to make panels for industries such as the automotive industry.

15. Pick and Place Machines (PNP)

- Price Range: $3000-$50K

- Used For: PCB assembly

- Material Compatibility: transistors, ICs, resistors, and other electronics

- Main Brands: Yamaha, Panasonic, Europlacer, Mycronic, Neoden, Hanwha, JUKI, DDM Novastar

- CNC Machine Tool: vacuum nozzle picking electronics and placing on circuit board

- Tolerance: 0.001″(0.03mm)

Pick-and-place CNC machines lift electronic components and place them on an electronic board. This type of CNC machine is widely used in the electronics industry and the making of cell phones, TV, computers, and nearly all devices with electronics.

However, not all pick-and-place machines are CNC machines. Some are a type of robot.

Most electronic circuit boards have surface-mounted components. A pick and place machine uses a vacuum nozzle to pick up these components from a tape and place them accurately on the board using its CNC controller.

How to pick the right type of CNC machine for you

To select the right CNC machine, ask these two questions, first:

- What shape do you want to create?

- What material?

Then, see the table below to spot the appropriate CNC machine.

| CNC machine | Shape | Material |

|---|---|---|

| Laser cutter | 2D cut-through – engraving | Sheets of metals and nonmetals |

| Waterjet cutter | 2D cut-through | All materials |

| Plasma cutter | 2D cut-through | Conductive materials |

| Oxy-fuel cutter | 2D cut-through | Ferrous metals |

| Drag Knife – Tangential knife | 2D cut-through | Sheets foam, rubber, textiles, fiberboard, vinyl, sandblast foil, flex, flock |

| Wire EDM | 2D cut-through only from the edge or drilled hole | Conductive materials, typically hard metals |

| CNC router | 3D pattern | Sheets of wood, PVC, MDF, foam, plastic, glass, acrylic, stone |

| CNC mill | 3D pattern | metals (steel, aluminum, brass, zinc, titanium), thermoset plastics |

| EDM | 3D pattern | Conductive materials, typically hard metals |

| 3D printer | 3D pattern | Resin, plastic, metals, graphene, polymers, carbon fiber |

| 2-axis Lathe | Cylindrical symmetry | Metals, wood, and rarely other materials |

| Multi-axis lathe | Cylindrical symmetry + 3D pattern | Metals |

| Grinding | Flat surface finish – OD and ID grinding | All materials, especially extremely hard metals |

| Drilling machine | Drill holes | Most materials, typically wood, metals |

If you have multiple choices, investigate the price, other capabilities, and operational costs.

FAQs:

What are the 5 common types of CNC machines?

The 5 common types of CNC machines are CNC milling machines, CNC routers, CNC lathes, CNC laser cutting machines, and 3D printers. Other less common types include CNC grinders and EDM machines.

What is the most commonly used CNC machine?

The most commonly used CNC machine in the industry is CNC mills. The most common CNC machine for woodworking and cabinet-making is the CNC router.

How many different CNC machines are there?

There are 15 main types of CNC machine, but there are also others including speculative picks like XY plotters, inkjet printers, and more. You could also arguably count 5-axis CNC machines or automatic tool changers as separate machines, or count the various CNC bending machines as different machines.

Related posts: