11 Best CNC Software 2024 (Router Controller, CAD-CAM)

With such a variety of CNC router software on the market, it can be a pain to figure out which covers your needs without being overly complicated. In this guide, I’ll compare ... Read more

With such a variety of CNC router software on the market, it can be a pain to figure out which covers your needs without being overly complicated. In this guide, I’ll compare ... Read more

Here’s a list of all the major CNC router and CNC machine 2023 Black Friday deals, and links to their insane range of discounted offers. We also have an article covering the ... Read more

In this article, we’ll look at the top CNC router accessories and how they can make your life much easier when cutting, scoring, and engraving. Some on our list are essential must-haves, ... Read more

CNC routers are used in a wide range of industries, including making furniture, doors, cabinets, in woodworking, creating beautiful musical instruments, and much more. I’ve used CNC routers for years, and even ... Read more

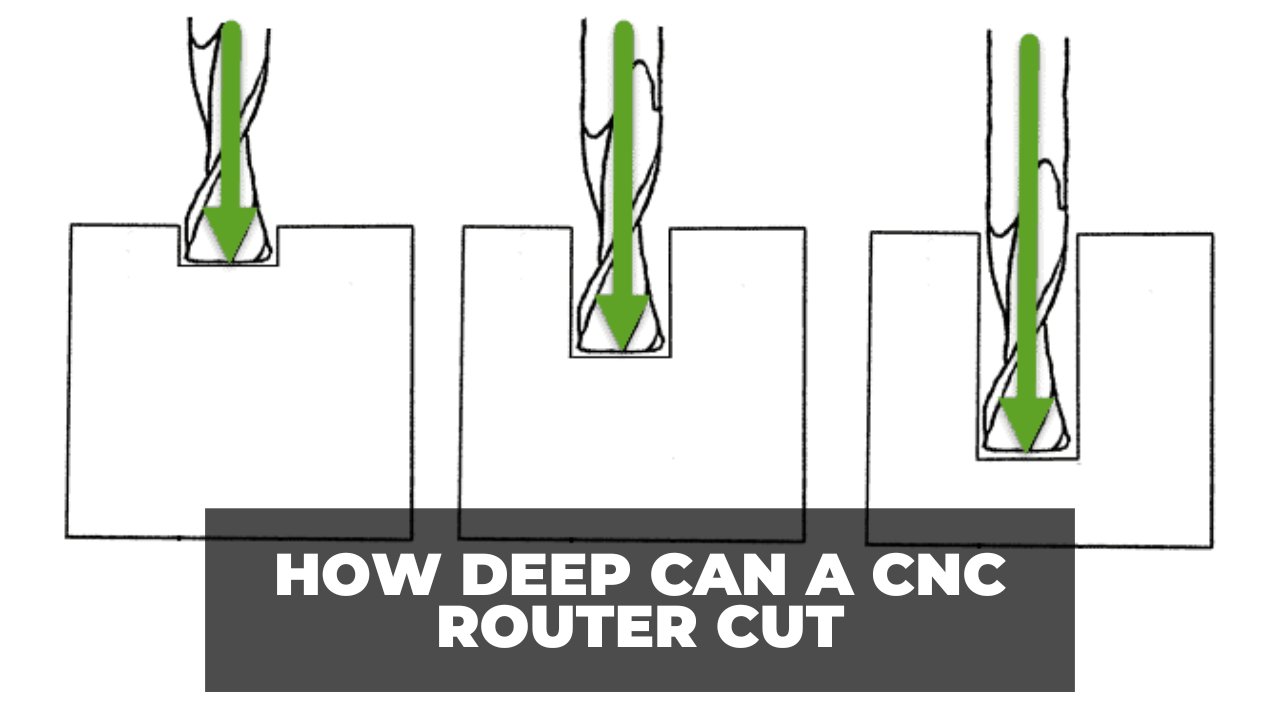

Generally, CNC routers can cut up to about an inch in one pass, and different CNC machines can cut maximum depths of between 1-7 inches. Though, how deep a CNC router cuts ... Read more

A CNC machine can cost anywhere from a hundred couple of dollars to tens and even hundreds of thousands, depending on the type of CNC machine it is, the size and rigidity, ... Read more

The main differences between CNC mills and CNC routers are that CNC mills are better for hard materials like steel, have a larger Z-axis movement and are great for tall material blocks, ... Read more

I have been a professional CNC programmer in a shop for over 15 years, and in this article I’ll explain the basics of CNC programming, how you can learn CNC programming, and ... Read more

Looking for the best 2×4 CNC router kits to elevate your projects and improve your efficiency? This guide cuts will walk you through my hands-on experience with all the top machines. The ... Read more

X-Carve was a great machine at the time, a ported version of an older Shapeoko. But, since then, X-Carve haven’t really innovated, and the machine is mostly the same as it was ... Read more

A bit is one of the most important parts of a CNC router – but the wide variety of different shapes, sizes, and functionality can mean it’s difficult to know where to ... Read more

Looking to unlock the full potential of 3018 CNC routers without breaking the bank? You’ve come to the right place. I’ve tested the best 3018 CNC routers under $500 – and came ... Read more

We previously tested the 3D printer toolhead of the Snapmaker 2.0, and found it to be the best 3-in-1 3D printer on the market. Today, we’re going deep into the laser cutter ... Read more

If you’ve ever removed material with your CNC machine, you have come across a variable in your CAM software called stepover size. In this guide, I’ll demystify the relationship between stepover size ... Read more

The key to transforming your CNC hobby into a lucrative enterprise is by using ideas that actually sell – and I’m here to show you exactly how This guide will step you ... Read more

While Pocket NC is one of the most popular 5 axis CNC machines on the market, the small working area (4.3 x 5 x 3.5”) and higher price relative to your average ... Read more

You have the choice between two types of laser engraver 3D printer combos: Specially designed machines naturally produce better results, but they’re more expensive. Laser kits can be as cheap as $50, ... Read more

With the best open-source CNC routers, you have the freedom to build your machine from the base up and customize it however you like. These machines are able to deliver exceptional precision, ... Read more

The best 4 axis CNC routers have better, more flexible manufacturing capabilities – but they’re more expensive than standard 3-axis hobbyist CNCs. In this article, I’ll recommend the best 4-axis CNCs for ... Read more

If you’re looking for an affordable CNC router for your home, there’s no shortage of options available – but how do you know which is the best budget CNC router for you? ... Read more

For many, starting a CNC business is a dream job. You get to spend your days doing something you’re passionate about, with the potential to earn far more than you would in ... Read more

In this guide I’ll share my hands-on experience with the most popular wood CNCs available, comparing them across important factors like material compatibility, ease of use, and size so you can find ... Read more

In this article, we’ll discuss two main types of machines: CNC routers (which can cut soft metals like aluminum) and CNC metal mills (designed to handle harder metals like steel, stainless steel, ... Read more

CNC routers come in all shapes and sizes, from small benchtop machines to large industrial machines – and one of the most popular is 4×4 CNC routers (or “4 foot by 4 ... Read more

The controller is the brain of any CNC, 3D printer, or laser. The CNC controller interacts with the control software to receive the G code and then plans the motion of your ... Read more

The spindle you use has a significant effect on everything from the run-off to the cutting speed, so choosing the right one for your project and material will result in more accurate, ... Read more

There are plenty of CNC shields for Arduino controllers, like GRBL and Marlin. If you are also developing an Arduino controller for your CNC, laser, or 3D printer, finding a good CNC ... Read more

Whether you plan to sell custom wooden wares on Etsy, or need a more professional CNC router for prototyping or commercial part production, there’s a tool to match your project and budget. ... Read more

You can do several things if you are dissatisfied with your stepper motor’s performance. You can change the stepper motor or the stepper motor driver or modify your stepper motor wiring (unipolar, ... Read more

CNC routers are great for cutting into thicker wood, while laser engravers are perfect for delicate features and cutting sharper corners. Combine them in a combo machine and you’ve got the perfect ... Read more