11 Best CNC Software 2024 (Router Controller, CAD-CAM)

With such a variety of CNC router software on the market, it can be a pain to figure out which covers your needs without being overly complicated. In this guide, I’ll compare ... Read more

With such a variety of CNC router software on the market, it can be a pain to figure out which covers your needs without being overly complicated. In this guide, I’ll compare ... Read more

CAD CAM software is used by hobbyists and professionals across a wide range of applications, from CNC machining to dentistry. But how do you go about finding the best CAD CAM software? ... Read more

CNC machining is a powerful technology that automates the carving, drilling, and shaping of materials. It only requires programming specific parameters into a machine and letting it do all the heavy lifting ... Read more

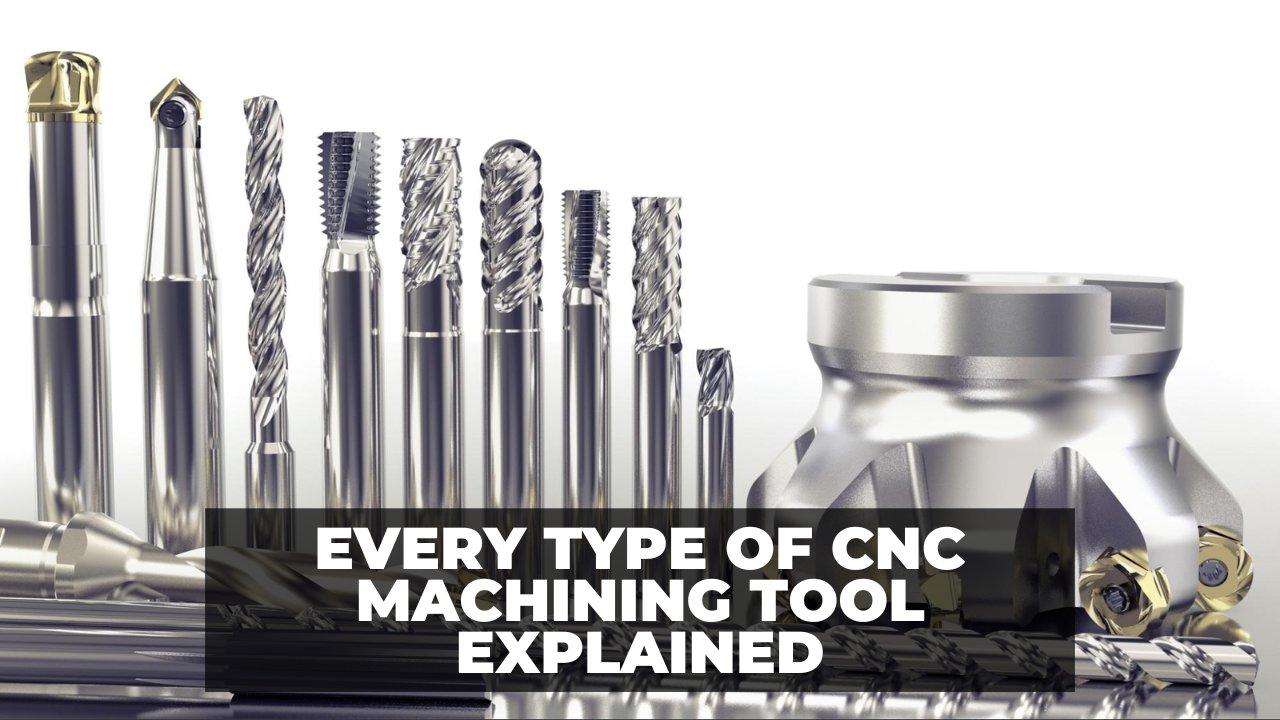

The right CNC machine tool is crucial for an accurate project, maximizing productivity, and extending tool life. In fact, using the wrong CNC tool affects: This article will explore the different types ... Read more

There are 15 different types of CNC machines, each with their own unique capabilities. The most common types include milling machines, lathes, routers, and grinders. These are the 15 types of CNC ... Read more

CNC terminology and acronyms can be confusing and technical, especially for beginners. So, we’ve put together this comprehensive CNC terminology guide of the terms often used in CNC machining circles. From “2D” ... Read more

A CNC machine can cost anywhere from a hundred couple of dollars to tens and even hundreds of thousands, depending on the type of CNC machine it is, the size and rigidity, ... Read more

CNC (computer numerical control) and NC (numerical control) are two different types of machining tools. They both transform stock materials into a finished product or part. The main difference between NC and ... Read more

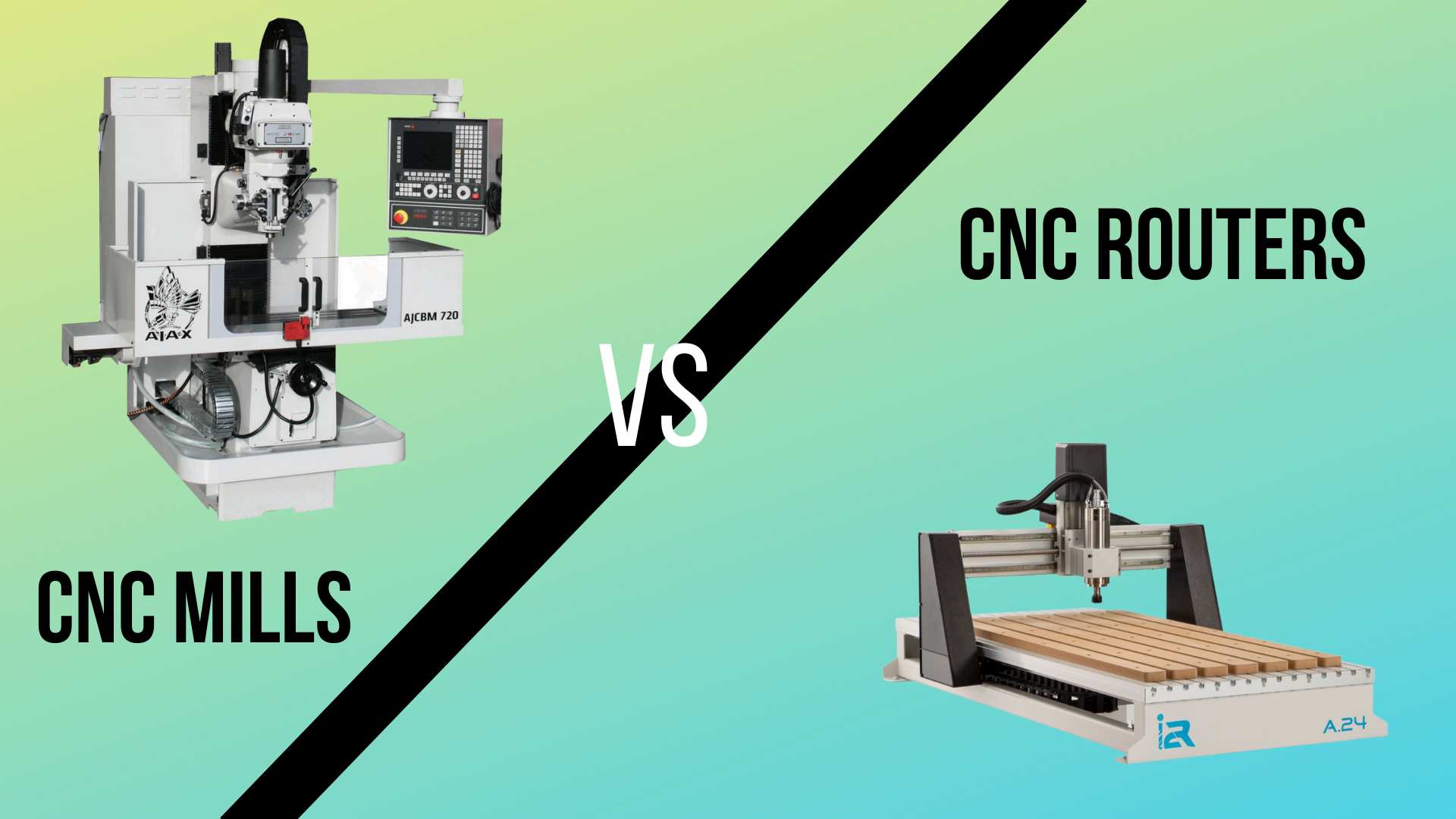

The main differences between CNC mills and CNC routers are that CNC mills are better for hard materials like steel, have a larger Z-axis movement and are great for tall material blocks, ... Read more

I have been a professional CNC programmer in a shop for over 15 years, and in this article I’ll explain the basics of CNC programming, how you can learn CNC programming, and ... Read more

A bit is one of the most important parts of a CNC router – but the wide variety of different shapes, sizes, and functionality can mean it’s difficult to know where to ... Read more

If you’ve ever removed material with your CNC machine, you have come across a variable in your CAM software called stepover size. In this guide, I’ll demystify the relationship between stepover size ... Read more

The key to transforming your CNC hobby into a lucrative enterprise is by using ideas that actually sell – and I’m here to show you exactly how This guide will step you ... Read more

Looking for inspiring CNC furniture plans and project ideas? Every DIY enthusiast knows building your own furniture makes for the most rewarding homemade adventures. In this article, I’ve curated a collection of ... Read more

Whether you choose to utilize a CNC shield or go without one, understanding the differences in connecting your stepper motor is crucial. In this comprehensive guide, we will delve into the intricacies ... Read more

If you’re looking for an affordable CNC router for your home, there’s no shortage of options available – but how do you know which is the best budget CNC router for you? ... Read more

In this guide I’ll share my hands-on experience with the most popular wood CNCs available, comparing them across important factors like material compatibility, ease of use, and size so you can find ... Read more

Finding the right CNC mill for you isn’t always easy. For starters, most CNC milling machines are very expensive and designed for industrial settings, so finding an affordable yet high-quality machine can be ... Read more

CNC, or Computer Numerical Control, encompasses the manufacturing process where machines cut, carve and form parts based on computer codes that control the cutting tool’s speed and movement. These machines cut metals, ... Read more

In this article, we’ll discuss two main types of machines: CNC routers (which can cut soft metals like aluminum) and CNC metal mills (designed to handle harder metals like steel, stainless steel, ... Read more

CNC routers come in all shapes and sizes, from small benchtop machines to large industrial machines – and one of the most popular is 4×4 CNC routers (or “4 foot by 4 ... Read more

The controller is the brain of any CNC, 3D printer, or laser. The CNC controller interacts with the control software to receive the G code and then plans the motion of your ... Read more

The spindle you use has a significant effect on everything from the run-off to the cutting speed, so choosing the right one for your project and material will result in more accurate, ... Read more

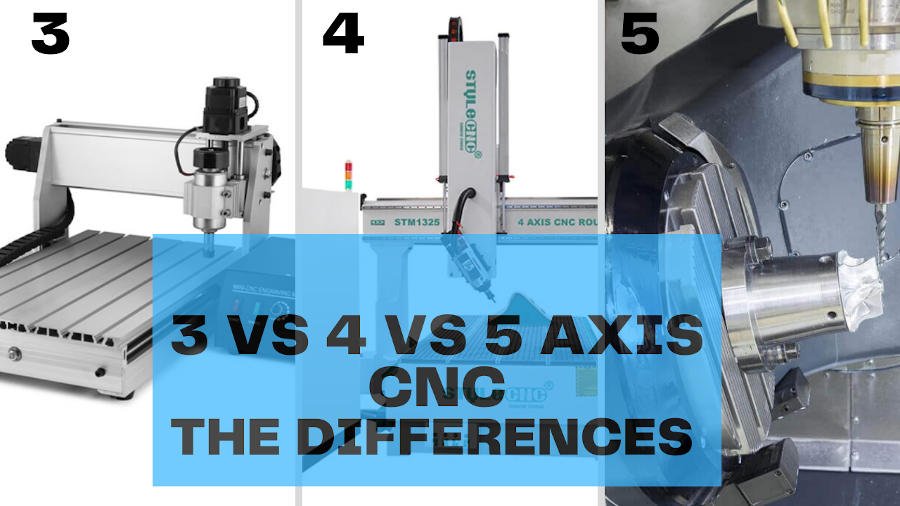

When it comes to buying a CNC machine, the first and perhaps most important consideration is whether you need a 3 axis CNC router, a 4 axis CNC router, or a 5 ... Read more

Whether you plan to sell custom wooden wares on Etsy, or need a more professional CNC router for prototyping or commercial part production, there’s a tool to match your project and budget. ... Read more

If you are about to cut or mill anything with your CNC machine, understanding feed rates and RPM speeds is vital. They will significantly affect your tool life, surface finish, and machining ... Read more

You can do several things if you are dissatisfied with your stepper motor’s performance. You can change the stepper motor or the stepper motor driver or modify your stepper motor wiring (unipolar, ... Read more

The best entry-level CNC plasma tables will help beginners leverage numerical control to enjoy far easier and more accurate cutting. But they’re not all created equal. In this guide I’ll share my ... Read more

Wire EDM is a type of CNC machining technology capable of producing shapes and structures that are next to impossible with other CNC methods — and can give you incredible results. In ... Read more

The best CNC simulators will allow you to easily test run projects without the risk – and in this guide, I’ll be ranking my experience with free and paid options. CAMotics is ... Read more