X-Carve was a great machine at the time, a ported version of an older Shapeoko. But, since then, X-Carve haven’t really innovated, and the machine is mostly the same as it was all those years back.

Hence, I now recommend these alternatives instead of the X-Carve for your next hobby CNC router.

| Name | Starting Price | Work Area | Where to buy |

|---|---|---|---|

| Shapeoko 5 Pro | 2×2: $3200; 4×2: $3500; 4×4:$3750 | 35.5″ x 35″; 60″ x 35″; 60″ x 59″ | Matterhackers here |

| Shapeoko 4 | Standard: $1,700 XL: $2,050; XXL: $2,300 | 17.5″ x 17.5″; 33″ x 17.5″; 33″ x 33″ | Matterhackers here |

| Shapeoko Pro | Standard: $2,400 XL: $2,600; XXL: $2,800 | 17.5″ x 17″; 17.5″ x 33″; 33″ x 33″ | Matterhackers here |

| Onefinity CNC Woodworker X-35 | NA | 32″ x 32″ | Matterhackers here |

| OpenBuilds LEAD CNC Machine | 1010 Full: $2396; 1515 Full: $2856 | 46”×49”; 29”×32” | OpenBuilds here |

| Avid CNC CRP4824 | $3,095 | 49-1/2″ x 25-3/4″ | AvidCNC here |

Reasons NOT to Buy an X-Carve

- Rigidity: X-Carve bends too easily if you push its gantry down, and can’t carry heavy loads. The culprits are the weak aluminum body, the motion structure, the Y-axis being supported only at the ends, the narrow belts, the small extrusions, and the v-wheels.

- Speed and depth of cut: for the above reason you have to use a lower feed rate and smaller depth of cuts with X-Carve, or you’ll get a lot of inaccuracy and chatter.

- Odd-Sized work area: while it has a big working area, it doesn’t reach the important 4’ milestone on the X-axis (not that its rigidity even allows a bigger work area). So, you have to pre-cut a 4*8 sheet before putting it in. As a result, the X-Carve is neither small enough to gain a footprint advantage, nor big enough to be a full-fledged sheet cutter.

- Not suitable for constant use: if you want to run the CNC for long hours or make money with it, you’ll need a spindle. But X-Carve only offers 300W DC spindles, which are not up to the task. This is because the X-Carve will bend if you install a heavy spindle, and ruin your cuts. In fact, the list of approved spindles is very short in their wiki, with only two 800W AC spindles.

- Long assembly time: Inventables states that the X-Carve takes 16 hours to assemble.

- Maintenance: X-Carve’s v-wheels are notorious for gaining play under force. You’ll have to adjust them regularly. V-wheels work with 3D printers, but they’re not sturdy enough for CNCs.

- Controller: although most beginner-level CNCs including X-Carve use GRBL, one of my recommendations in this article has a better controller.

The Best X-Carve Alternatives in 2024

1. Shapeoko 5 Pro – Best X-Carve Alternative Overall

- Price: Check latest price at Matterhackers here

- Work Area: 60″ x 35″

- Also available in: 35.5″ x 35″ and 60″ x 59″

To put it blunt: the Shapeoko 5 Pro is better than the X-Carve in every possible way. It’s a better comparison to compare the Shapeoko Pro with the X-Carve Pro, but really it’s better than the X-Carve Pro despite being half the price.

Work area – 4’ milestone reached

The Shapeoko 5 comes in three sizes: 2×2, 4×2, and 4×4. The larger work areas are affordably priced, too, so, if you have enough room, I recommend the 4×2 and 4×4 because you can directly feed in a 4×8 plywood sheet, something an X-Carve can’t do.

From personal experience, it becomes a big bother when I have to cut a plywood sheet into smaller pieces with a saw before putting them into my CNC. But with a 4×4 CNC, you can put half of the sheet into the machine while the other half hangs out the back. Then when you’re done, just slide in the other half.

Drive system

The Shapeoko 5 Pro has ballscrews and linear rails on all axes, while the X-Carve uses belts and v-wheels on the X and Y. This makes the Shapeoko 5 more rigid and almost maintenance-free, whereas you should regularly adjust the X-Carve’s belts.

Superior structure and rigidity

The Shapeoko 5’s structure is much more rigid than the X-Carve. It has much thicker machined extrusions that are sturdier and more accurate. Plus, the design is simply better since the Shapeoko table also supports the weight of the Y-axis.

All of this means that Shapeoko 5 Pro can handle tougher materials, deeper cuts, and much higher feed rates than X-Carve.

Better spindle options

Also, if you’re buying a CNC for a business and plan on running it for long hours, I recommend Shapeoko’s 1.2kW spindle and VFD package that could run all day. You don’t have many spindle options with the X-Carve as it’s mostly a casual hobbyist machine.

Easy assembly

Shapeoko 5 Pro ships with X and Y units pre-assembled. All you have to do is assemble smaller parts and start cutting. In contrast, X-Carve’s 16-hour assembly was already notoriously harder than even the older Shapeokos.

Support

Shapeoko covers for any issues (or mistakes) in the first 60 days. So, if you’re learning, don’t worry about destroying your Shapeoko.

However, it still uses the same controller

Finally, Shapeoko 5 uses the same GRBL controller as X-Carve. This is among the few areas Shapeoko doesn’t beat X-Carve.

2. Shapeoko 4 – Most Affordable X-Carve Alternative

- Price: $2,050 — Check latest price at Matterhackers here

- Working Area: XL: 33″ x 17.5″

- Also available in: 17.5″ x 17.5″ and 33″ x 33″

If the Shapeoko 5’s higher cost is a deal breaker for you, the cheaper Shapeoko 4 is similarly priced to the X-Carve, but is a better machine.

Similarities

Like the X-Carve, Shapeoko 4 also uses belts and v-wheel on the X and Y axes, while using lead screws on the Z. However, Shapeoko’s 15mm belts are stronger than X-Carve’s 9mm belts.

Another flawed similarity is that Shapeoko 4 also comes in odd sizes that are big, yet don’t make the 4’ milestone I explained earlier. If you want a CNC with a convenient work area for 4×8 sheets, go with Shapeoko 5.

They also both use Arduino boards with GRBL firmware, which is common among hobbyist CNCs but not as high quality as the Builbotics controller seen in the Onefinity CNC series.

Differences

Size flexibility

The Shapeoko 4 is available in three different sizes in contrast to the X Carve being available in just one.

The Shapeoko 4 XXL is the most similar in size, but with a larger 33”x33”x4” working area, while the smaller Standard and XL size options give you more freedom to choose the right machine for your budget and workshop space.

Sturdier structure for cutting tougher materials

Both these CNC routers are built with aluminum extrusions, but the extrusions on the Shapeoko 4 XXL are significantly larger and heavier.

To be precise, the Shapeoko’s extrusions measure 85x55x5mm in contrast to the X Carve’s 40x40x3mm, with the added weight making the Shapeoko considerably more stable.

Also, Shapeoko’s extrusions support the Y-axis and gantry’s weight providing a defense against bending forces, while X-Carve’s Y-axis is only supported at the ends.

All of this means Shapeoko 4 can cut tougher materials like aluminum than the X-Carve much faster, and it has been shown to cut wood up to as twice as fast. The X-Carve can still be used to cut soft metals, but can’t cut aluminum in the way Carbide 3D have proven the Shapeoko can on their YouTube tests.

Easier assembly

Due to the Shapeoko 4 parts coming preassembled, it’s quicker to get up and running.

Both are very similar in terms of upgradability, with laser engraver modules, Z-axis upgrades, and extension kits available for each router.

However, it has less popular software, and Shapeoko doesn’t come with a router

Generally, Inventables’ Easel 3 software is better than Carbide 3D’s Carbide Create and Carbide Motion package, and once set up it’s one of the most user-friendly CNC routers you can buy.

The X Carve also comes with a Makita router included, whereas Shapeoko users need to order a Makita or Carbide compact router separately.

But overall, if you’re looking for a sturdier, bigger alternative that’s better at cutting metal, the Shapeoko 4 offers just that for only a slightly higher price. For more detail, you can also read our more in-depth Shapeoko 4 vs X Carve comparison.

3. Shapeoko Pro – Best X-Carve Alternative Under $3000

- Price: Check latest price at Matterhackers here

- Work area: Standard (17.5″ x 17″)

Also available in: XL: (17.5″ x 33″) x and XXL: (33″ x 33″)

Our opinion on the Shapeoko Pro is mostly the same as Shapeoko 4, but with two advantages:

- It has linear rails instead of belt drives. This is an important upgrade that adds to rigidity. Also, you don’t have to constantly replace broken wheels and adjust the tension.

- Shapeoko Pro ships with a bit setter, which you can also buy optionally for Shapeoko 4. The bit setter does what X-Carve’s Z-probe does, but in my opinion, it’s nicer. The bit setter sits at the end of the table and the machine saves its coordinates. So, whenever you press the set tool Z, the machine goes there and automatically measures where the tool’s tip is and sets the z offset automatically.

It’s worth nothing that Carbide 3D has said that they may discontinue either the Shapeoko 4 or Shapeoko Pro. But until they do, we’ll have both of them on our list.

4. Onefinity CNC Woodworker X-35 – Fastest X-Carve Alternative

- Price: Check latest price at Matterhackers here

- Working area: 32″ x 32″

Having tested several popular CNC routers against the X Carve, I believe the Onefinity CNC Woodworker X-35 is one of the best X-Carve alternatives around.

Here are the main benefits of the Onefinity over the X-Carve:

- It uses a ball screw mechanism that’s better than the X Carve’s belt drive and Z-axis lead screw

- The Onefinity CNC’s Buildbotics controller is significantly better than the X Carve’s standard GRBL board

- You get a slightly larger working area with the Onefinity CNC

- The Onefinity is made of steel and offers more stability, rigidity, and durability

- It is much easier and quicker to assemble than the X Carve

These different Onefinity machines are actually the same machine but in four different sizes, ranging from a small desktop machine to a large 4ft x 2.6ft. You can read more about this in my Onefinity CNC review. In contrast, the X Carve comes in just one size.

The Woodworker X-35 is the closest in size to the X Carve, offering a 32”x32” working area in contrast to the X Carve’s 29.5”x29”. While there’s only a few inches in it, most hobbyists will prefer that extra space, especially considering they’re a similar price.

Stability and sturdiness

Whereas the X-Carve is made of an aluminum frame and offers decent stability, the Onefinity is constructed using hollow steel shafts. Steel is stronger and makes it sturdier and more rigid, while the hollow shafts help minimize flexing and vibrations. This makes the Onefinity an incredibly stable, and therefore precise, machine.

Better metal cutting

One thing that many people question about the X Carve is its metal cutting ability. While you can cut soft metals like aluminum with it, it’s not ideal for this. In contrast, the Onefinity CNC is widely referenced as a quality metal cutter, and people have even used it to cut thin steel.

Electronics and controller

Whereas the X Carve uses a standard Arduino board with GRBL firmware, similar to many other affordable CNC routers, the Onefinity CNC uses a Buildbotics controller.

This powerful controller uses a Raspberry Pi board, so you don’t need to use a PC to run the Onefinity. There’s the option to add an 8” touchscreen display and even a “joypad” styled on an Xbox controller, which provides an incredibly intuitive CNC experience.

The Onefinity base kit with the Buildbotics controller actually costs less than the X Carve too, so it’s great value for money.

However, the software is not as good as X-Carve

Now, this isn’t to say the Onefinity CNC is better than the X Carve in every way. For example, with the X Carve you get a 3-year license for Easel Pro, a powerful, user-friendly all-in-one CNC software with CAD, CAM, and motion control functions. All you get with the Onefinity CNC is a basic control software preprogrammed onto the Builbotics controller.

However, software is always something you can get separately. In my view, the significantly better mechanical and electrical components make it worth spending the extra money on the Onefinity.

Read more: our Onefinity CNC review

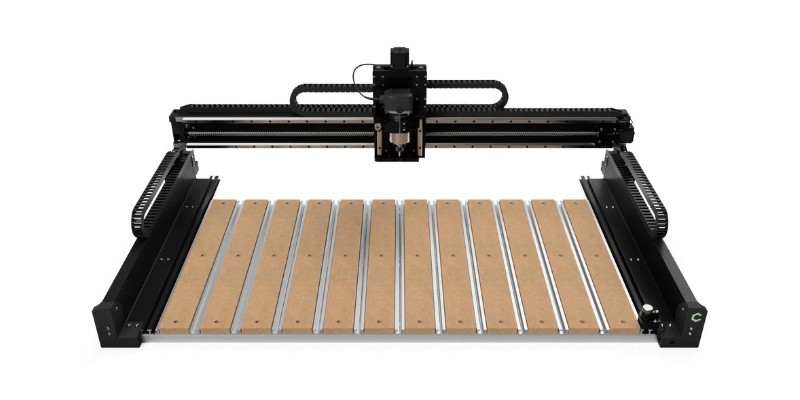

5. OpenBuilds LEAD CNC Machine – Best Work-Area for Money X-Carve Alternative

- Price: Check latest price here

- Work area: 46”×49” and 29”×32”

OpenBuilds LEAD CNC is an open-source machine, so you can use the design however you like, or just order the kit. OpenBuilds LEAD is very similar to the X-Carve in design overall, but it’s bigger.

Size and price

You can order the OpenBuilds LEAD in two sizes. The table below shows the two sizes and prices of OpenBuilds LEAD vs X-Carve.

| Machine | Work Area | Price |

|---|---|---|

| X-Carve | 29.5”×29.5” | $2599 |

| LEAD 1010 Fully Loaded | 29”×32” | $2395 |

| LEAD 1515 Fully Loaded | 46”×49” | $2855 |

The LEAD 1515 almost reaches the 4’ milestone. You can put a 4×8 plywood sheet in it, but the machine’s work area is a little smaller, leaving an inch of uncut material on each side. It would be better if the X-axis was 2” wider, but it still can take a full sheet.

Drive system, structure and stability

Both machines use v-wheel and belts on the X and Y axes and lead screws on the Z-axis.

However, OpenBuilds LEAD has larger aluminum extrusions, especially in the gantry. This is how it manages the larger work area.

Other differences

Among smaller distinctions, OpenBuilds ships with a RoutER11, which seems to be their rebranded router, whereas X-Carve ships with a Makita. X-Carve’s Makita is better, but you can also buy it for $80.

You also get OpenBuilds CAM and Control for free with this package (OpenBuilds Control is free anyway). Inventables’ Easel is much more popular at the moment, though it’s an online software.

6. Avid CNC CRP4824 – Best Professional X-Carve Alternative

- Price: Check latest price here

- Work area: 49-1/2″ x 25-3/4″

All of the CNC routers I’ve covered so far are very much hobbyist machines, although the likes of the Onefinity CNC and Shapeoko 4 are good enough for small, home business production.

However, if you’re looking for a more professional, industrial-grade alternative, I recommend checking out an Avid CNC router.

Avid CNC makes a wide range of professional CNC machines that are excellently made, and the CRP4824, a 2×4 CNC router kit is the most valid alternative to the X-Carve in my opinion.

The reason I’ve highlighted this particular Avic CNC model is that you get a very high-quality router that offers a significantly larger working area than the X Carve, but for just around $1,000 more.

It’s a 4×2 CNC, so you can process a 4×8 sheet without cutting it down with a saw. This is perfect if you want to start working on larger products or at faster, more demanding production rates.

It’s made of heavy-duty aluminum with steel plates for better stability, while the dual drive rack and pinion on the Y axis, rack and pinion drive on the X axis, and 5 start Acme lead screw drive on the Z axis makes for a very smooth, high-quality linear motion. These are significantly better than all the other machines on our list, and provide top-notch stiffness and all the power you need for cutting aluminum and soft metals with great precision.

As a result, this machine is considerably faster than all of the other alternatives I’ve listed.

The controller is also robust and better than GRBL. On the downside, the control software is Mach4, which costs $200 and is not as easy to use as GRBL, especially for beginners.

Also, the price doesn’t include a spindle, so you need to order that separately, which adds to the cost.

Also, bear in mind that these Avid CNC machines are not as user-friendly as the X Carve, which is specifically designed for beginners and amateur hobbyists. I wouldn’t recommend these to first-timers.

Factors To Consider When Choosing an X Carve Alternative

Rigidity and Drive System

Rigidity is one of the most important factors to consider, affecting both accuracy and speed.

From our recommendations, the order of most rigid to least is:

- AvidCNC CRP 4824

- Onefinity CNC

- Shapeoko 5

- Shapeoko Pro

- Shapeoko 4

- OpenBuilds LEAD

Price

The OpenBuilds LEAD is the most affordable X-Carve alternative. However, all the options on our list provide better and unique value for money than the X-Carve offers. At the top end, the Avid CNC CRP4824 starts at $3,095, aimed at professional or industrial-grade work.

| Product Name | Starting Price (USD) |

|---|---|

| Shapeoko 5 | 2×2: $3200 4×2: $3500 4×4: $3750 |

| Shapeoko 4 | Standard: $1,700 XL: $2,050; XXL: $2,300 |

| Shapeoko Pro | Standard: $2,400 XL: $2,600; XXL: $2,800 |

| Onefinity CNC Woodworker | NA |

| OpenBuilds LEAD | 1010 Full: $2396 & 1515 Full: $2856 |

| Avid CNC CRP4824 | $3095 |

Work Area

The Shapeoko 5 has the largest work area, with the 4×4 version able to handle full 4 by 8 sheets with no issue. The next best options are OpenBuilds LEAD 1515 and AvidCNC.

The table below summarizes the work areas of X-Carve alternatives from the best to the worst (not necessarily largest to smallest).

| Product Name | Work Area (X*Y) | Can It Take a 4×8 Sheet? |

|---|---|---|

| Shapeoko 5 | 2’×2′ 4’×2’ & 4×4 | Yes |

| OpenBuilds LEAD | 46”×49” & 29”×32” | Yes |

| AvidCNC | 4’×2’ | Yes |

| Shapeoko 4 and Pro | 33”×33” | No |

| Onefinity Woodworker X-35 | 32”×32” | No |

Speed

For speed, outperforms every other machine on our list by a large margin.

The order of fastest to slowest overall is:

- AvidCNC

- Onefinity

- Shapeoko 5

- Shapeoko Pro

- Shapeoko 4

- OpenBuilds LEAD

Ease of Use and Software

It’s doubly important for beginners to go for an easy-to-use machine. On our list, all Shapeokos and OpenBuilds are among the easiest to use (they share the same controller). Then, the Onefiniity, and the least beginner-friendly is the Avid CNC.

FAQs

What is better, Shapeoko or X-Carve?

Having tested the two against each other, I believe the Shapeoko 4 is better overall due to its superior stability, aluminum cutting, and larger size. However, the X Carve is a very user-friendly machine with a better software package.

Can you use other software with X-Carve?

Yes. While Easel Pro is optimized for the X Carve, as the controller is GRBL-based, you can use any GRBL control software and any CAD/CAM program of your preference.

For more related topics, here are some articles we recommend:

- Maslow CNC alternatives

- Pocket NC Alternatives

- Inventables X Carve alternatives

- Best DIY CNC router kits

- The best free, paid, and open-source CNC software

- The best cheap CNC routers

- 40+ CNC industry stats and facts