The new Snapmaker 2.0 10W High-Power laser module has just released for the Snapmaker 2.0 A250 and A350 models, so we had to test it out after enjoying the original kit so much.

We’ve previously reviewed the Snapmaker 2.0 A350 for two previous posts: testing it as a 3D printer, and as a CNC carver, laser, and the rotary attachment module. It impressed us in every area, and so testing the newest module for faster cutting of thicker materials was a no-brainer.

Having tested almost a dozen laser engravers and cutters, CNC routers and 3D printers, we put the new laser module through a variety of tests on wood, acrylic and metal, as well as using it with Snapmaker’s rotary attachment module, and here are our results.

Snapmaker 2.0 10W Laser: Main Specs

- Snapmaker 2.0 10W laser price: $399 — Available at Snapmaker Store here

- Work speed: up to 6000mm/s

- Maximum cutting depth: 8mm

- Auto focus

What Does the 10W High-Power Laser Do?

You can view the results that the original 1.6W laser delivered in our original CNC and laser review, and we were surprised it managed to cut thin wood to create a wooden storage box when we tested it.

But the new 10W laser head ups the ante and reaches new strengths, able to engrave on anodized aluminum, as well as cut through acrylic and wood up to 8mm thick.

In fact, here’s the full list of materials you can cut or engrave with the Snapmaker 10W laser:

- MDF

- Basswood

- Leather and artificial leather

- Stone

- Bamboo

- Anodized aluminum

- Dark glass

- Stainless steel

Testing the Snapmaker 2.0 10W High-Power Laser

To use the new 10W laser module with your Snapmaker 2.0 you’ll need to update the firmware, as well as Snapmaker Luban. We have had our Snapmaker 2.0 for a few months now and our current firmware needed updating for the new laser head.

You’ll also need to calibrate the 10W laser head once you’ve attached it and turned on the machine. If you’ve used the Snapmaker before, you’ll have plenty of calbration cards lying around, but the laser module comes with another for calibrating it to the laser bed, which then triggers the second step, finding the middle of the print bed and calculating material thickness using your laser target metal card.

This takes around 5 minutes, and then you’re ready to cut.

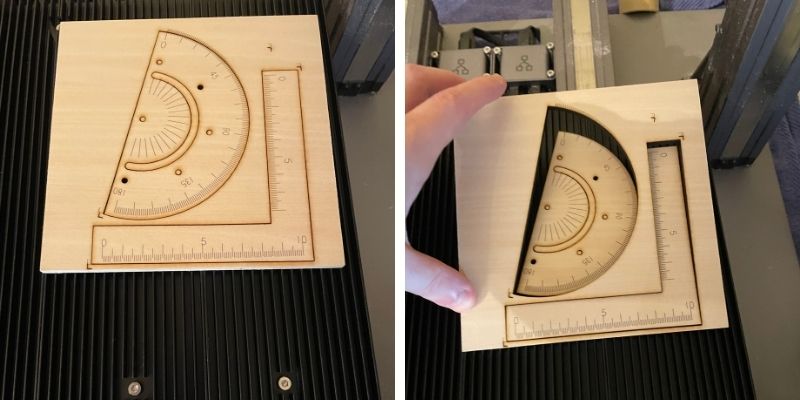

The first project we tried was a fun, practical wood cut from the 5mm basswood sheet that came with the Snapmaker 2.0 10W laser head. We used a model from Luban for two useful measuring tools: a protractor and a mitre square, with the outsides and some internal parts to be cut out, as well as engraving the lines for each millimeter for use measuring.

The job took 9 minutes, and left us with 2 cleanly cut wood measuring tools – I was really pleased with the quality. The cut was clean, and so fast compared to the previous 1.6W laser – at this rate, you could knock out 10-12 of any similarly sized design per hour, potentially a good money earner.

One part of the engraving was off, most notably on the protractor, but that was down to me not holding down the material well enough – next time I’ll use the clamps.

The next project was engraving a design on top of a thin, keyring-sized piece of anodized aluminum – probably the thing I was most looking forward to testing on the 10W High-Power Laser head. A tiny job, the entire laser marking process took just 45 seconds, and left a clear and contrasting line drawing of a wolf on the metal, though you can’t feel it if you run your hand over the anodized aluminum surface.

The ability to mark metal so easily and clearly is a big advantage for this more powerful laser, and I’ll be having fun marking stainless steel, aluminum and stone over the following months with this.

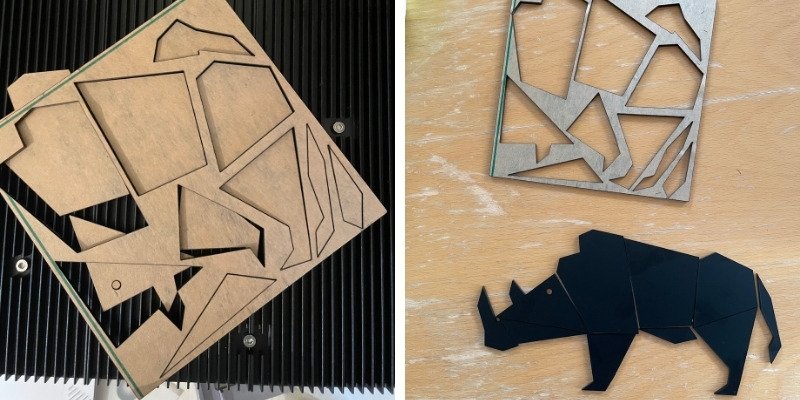

The last project I tried was on acrylic, as it can be tricky for some lasers. The 3mm black acrylic sheet was big enough to cut out a mini puzzle, so I gave that a go. The job took 15 minutes to cut around 12 pieces of acrylic out from the sheet, and like with the wood, provided a clean cut – every piece fell out of the sheet after the job finished; there were no almost-cut parts. The puzzle looked great and is a fun thing you can make for your kids, or a range of products that could sell well online, and at 15 minutes per run, could be a profitable laser project.

I’ll add more tests as I get to them, but having tried the 10W Snapmaker 2.0 Laser on wood, acrylic, and metal, and performed well with all, this seems like a fast, powerful and accurate laser that’s well built and has a host of advanced auto-calibration features to save you time and make you money.

Snapmaker 2.0 10W High-Power Laser Review: Is It Good?

Pros

✅ More powerful, faster, and more precise

Overall, we were impressed with the extra power and speed the 10W laser head offers. Whereas cutting out a box on softer wood took just under an hour on the 1.6W standard laser, the 10W laser works up to 8x as fast, and can cut thicker and tougher woods.

Though it’s not the fastest laser you’d ideally use to start a productive business with – read our best laser cutters for small businesses for our recommendations – it’s a big upgrade on the original, with up to 6000mm/min work speed when cutting 1.5mm basswood.

It engraved high-quality, contrasting intricate design on both flat material blocks, and on rounded material, so for any hobbyists looking to engrave custom images or designs for themselves or to test for a business, it’s a great add-on.

The Fast-axis Collimating (FAC) lenses help compress each of the two laser diode’s laser spot, combining them to offer high power, and much finer laser focus of 0.05mm x 0.2mm – also allowing for higher energy density. This combination of smaller laser focus and higher power makes for cleaner cuts, better details, and a better laser cutter and engraver overall.

✅ Easy to use software

Though 3D printing software like Cura are really intuitive and simple to use, laser software and CNC software – barring popular laser software Lightburn – are considered more complex, with many parameters that may spook beginner hobbyists.

Snapmaker Luban, Snapmaker’s in-house software, is easy to use, handles every single use in within one app (CNC, 4-axis CNC and laser, 3D printing, laser engraving and cutting) and does all without making it complex for the user. Even the 4-axis laser engraving with the 10W laser add-on was made simple

✅ Saves you space

One of the best things about the Snapmaker 2.0 is that being a 3-in-1 machine, it saves you owning three machines to do the same job and cluttering up your workspace. Naturally, you sacrificed performance in the laser in order to do this at a fair price, but now with the more powerful add-on, you can mimic standalone desktop laser engravers within one machine.

✅ One-stop-shop within the Snapmaker ecosystem

We highly recommend you use the laser with the Snapmaker 2.0 enclosure to filter out the fumes and deflect any harmful light from damaging your eyes. The good news is that if you already have the enclosure, for example for ABS 3D printing to reduce warping, you’re all set as the same enclosure serves all these roles.

Cons

? Expensive

The 10W laser is an upgrade on the standard 1.6W module, but still struggles vs CO2 lasers. OMTech’s K40 40W laser is only a hundred dollars more expensive, and comes loaded with 40W power for cutting through thicker materials and better marking engraving.

For more serious standalone laser uses or business use, consider upgrading to a standalone machine.

What does the Snapmaker 2.0 10W Laser come with?

- 1 sheet of 2mm anodized aluminum

- 1 sheet of 3mm acrylic

- 1 sheet of 5mm basswood

- A pair of eyewear for protecting your eyes against the laser.

- Quick start user guide

- Paper calibration card

- Metal laser centering block

- Accessories box containing:

- 5 cotton buds

- 1 washer

- 6 M4 x 8 screws

Is the 10W Laser Module Compatible with my Snapmaker?

The 10W laser is compatible with all Snapmaker 2.0 A350 and A250 models, and the AT and F versions of the Snapmaker 2.0.

What Snapmaker modules can you use with the 10W laser module?

You can use the 10W laser head with the laser rotary module, emergency stop button, enclosure, and air purifier.

Check out another modular CNC machine, the Stepcraft CNC D840.

Related Articles: